WOODOT

AI-powered mobile robot automating defect detection and repair in wood manufacturing

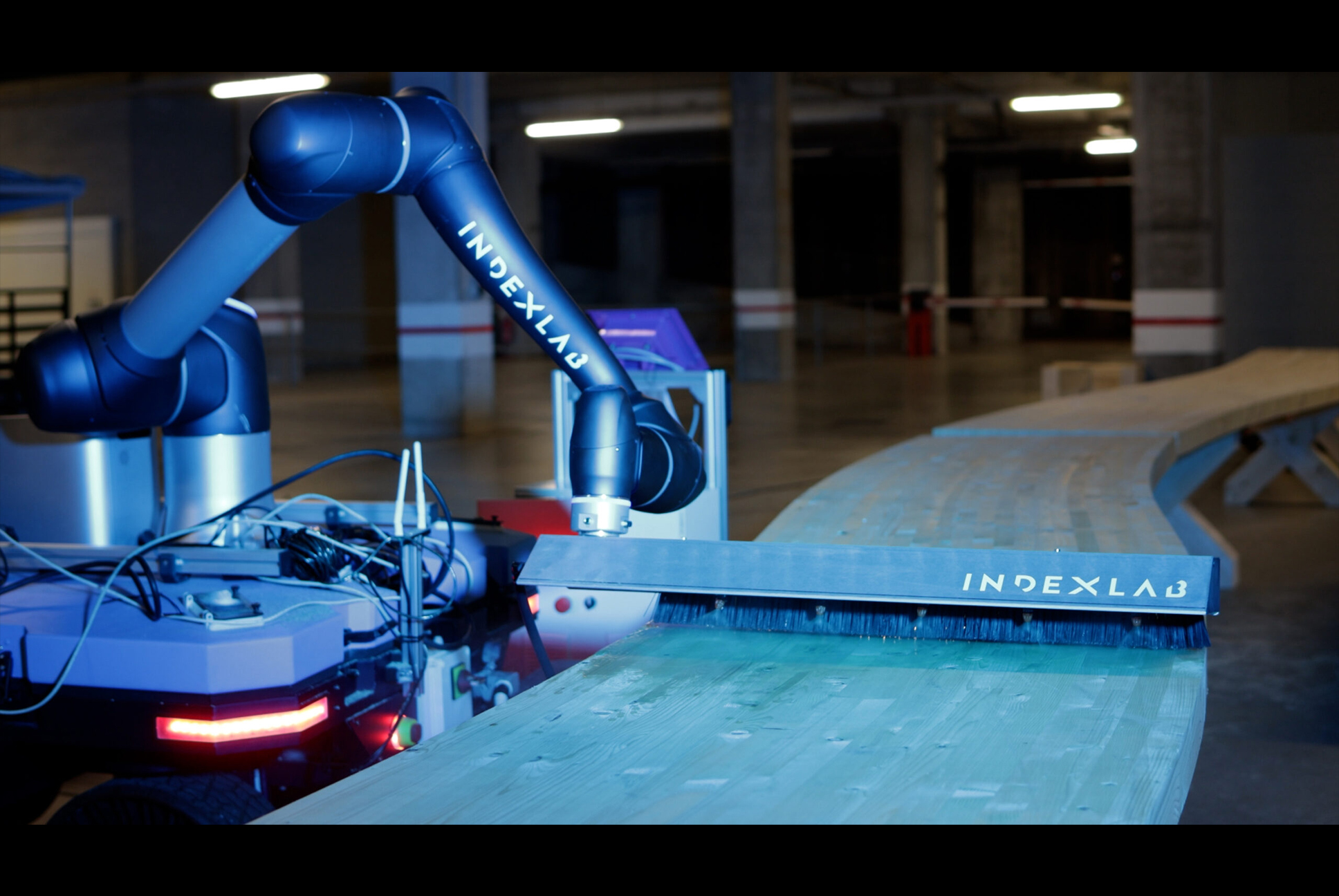

WOODOT is a robotic system for automated quality control and defect remediation in laminated timber beams. It integrates a six-degree-of-freedom robotic arm mounted on an autonomous mobile rover, equipped with a customizable end-effector for tasks such as defect detection, milling, sanding, and restoration material application. The system relies on an AI-driven vision model, trained to identify and process surface defects, outperforming manual inspection and commercial AI-based cameras.

Manual inspection and repair of wooden beams are labor-intensive, inconsistent, and inefficient, causing quality variation, material waste, and delays. WOODOT addresses this by integrating robotics, AI-based defect detection, and automated processing into one streamlined workflow to enhance accuracy, consistency, and efficiency while minimizing repetitive human tasks.

Building a fully autonomous quality control system involves challenges: the AI must distinguish defects from natural wood grain through extensive training and real-time adjustments; the robotic platform must navigate large, irregular beams with precise motion and adaptive path planning; and the system must switch tools seamlessly to transition between scanning, defect removal, and material application without interruption.

WOODOT consists of an autonomous mobile robot (AMR) that navigates predefined paths or maps its environment for on-site use. A six-axis robotic arm, equipped with a multi-functional end-effector housing a camera, milling cutter, and restoration tool, performs inspection and repair tasks.

The system operates in five phases: the AMR positions itself near a beam, aligning the arm for scanning; the AI vision system captures high-resolution images and analyzes defects in real-time; the arm mills damaged areas; and the end-effector applies wooden plugs or restoration material to complete repairs.

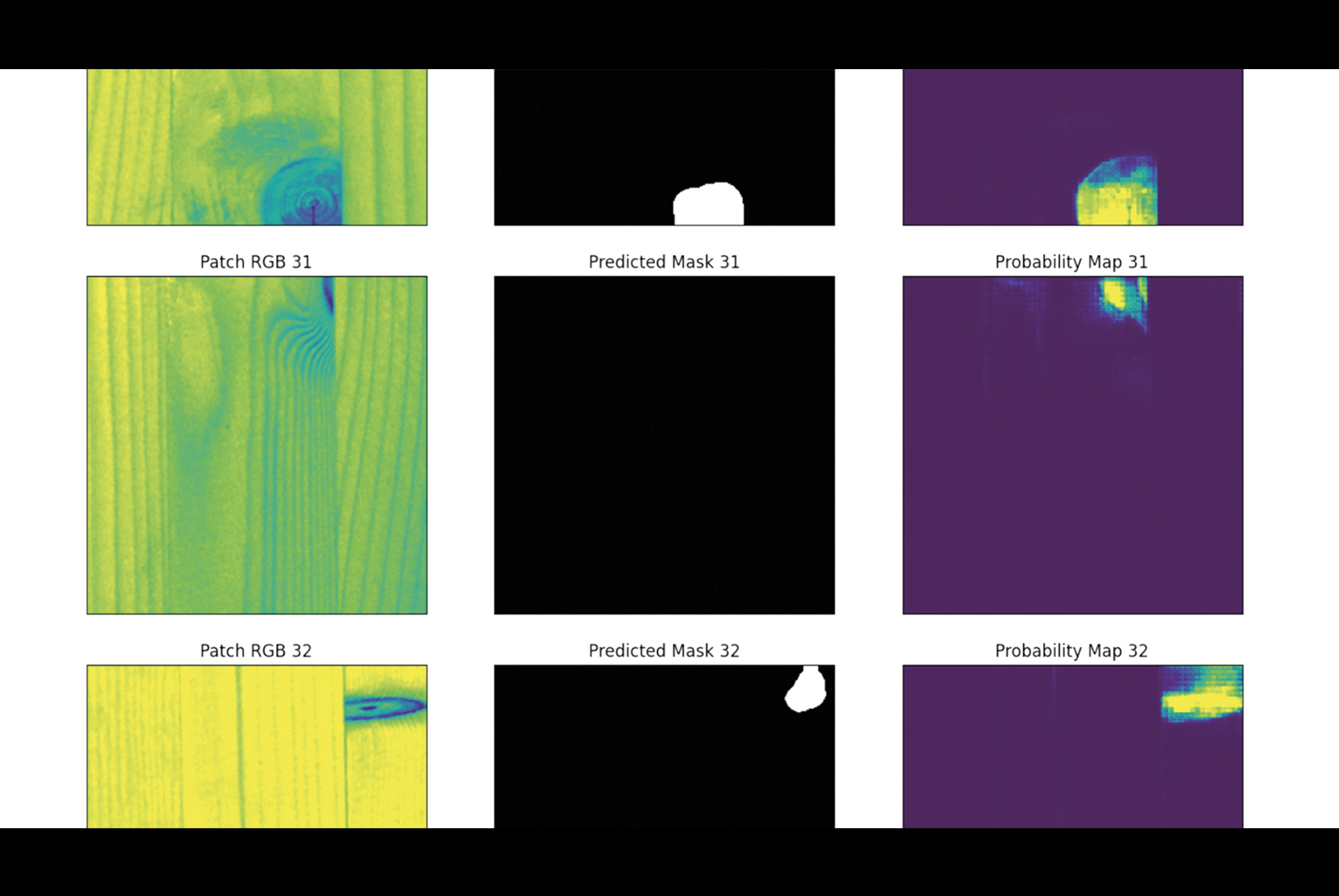

At its core is a deep learning segmentation model trained on custom datasets to detect knots, cracks, and scratches while ignoring natural grain. A real-time inference pipeline allows adaptation to various wood textures and types.

WOODOT demonstrated high accuracy in defect detection and repair. The deep learning model reduced false positives and misclassifications, improving defect identification.

Field tests validated the system’s ability to perform fully autonomous defect detection, milling, and restoration, removing the need for human intervention.

space

MATERIALS

Glued Laminated Timber (GLT)

PROCESSES

Milling | Robotic Wood Processing | Surface Finishing | Artificial Intelligence & Machine Learning | Vision System |

Autonomous Construction Equipment

space

ROLES

INDEXLAB developed the system architecture of WOODOT, integrating a 6-DOF robotic arm with a mobile rover platform, and designed a modular end-effector capable of executing defect detection and milling. Indexlab also trained and implemented a custom AI vision model for surface inspection.

STAKEHOLDERS

LOCATION

First exhibited at SAIE Fair in Bologna, Italy

YEAR

2024

space