DETEEKT

AI-powered defect detection system for prefabricated façades with immersive MR-based traceability

Deetekt proposes a new approach to quality control in the construction of curtain walls for multi-storey buildings. The project addresses the challenge of early defect detection in building components, improving process efficiency and continuity. The integration of computer vision and immersive technologies enables automatic anomaly detection during the material procurement phase. MR-assisted visualization simplifies reporting and traceability operations, reducing the cognitive and physical workload of operators.

In the field of prefabricated building facades, quality control is often fragmented, slow, and prone to human error. Deetekt aims to overcome these limitations through the use of AI-based vision systems. The goal is to develop an operational workflow capable of automatically detecting defects, accurately tracking them, and supporting subsequent assembly phases.

The project is set in a context where construction site digitalization is still limited. Existing solutions focus on isolated phases of the process. Deetekt, on the other hand, adopts an integrated approach that leverages robotic arm automation.

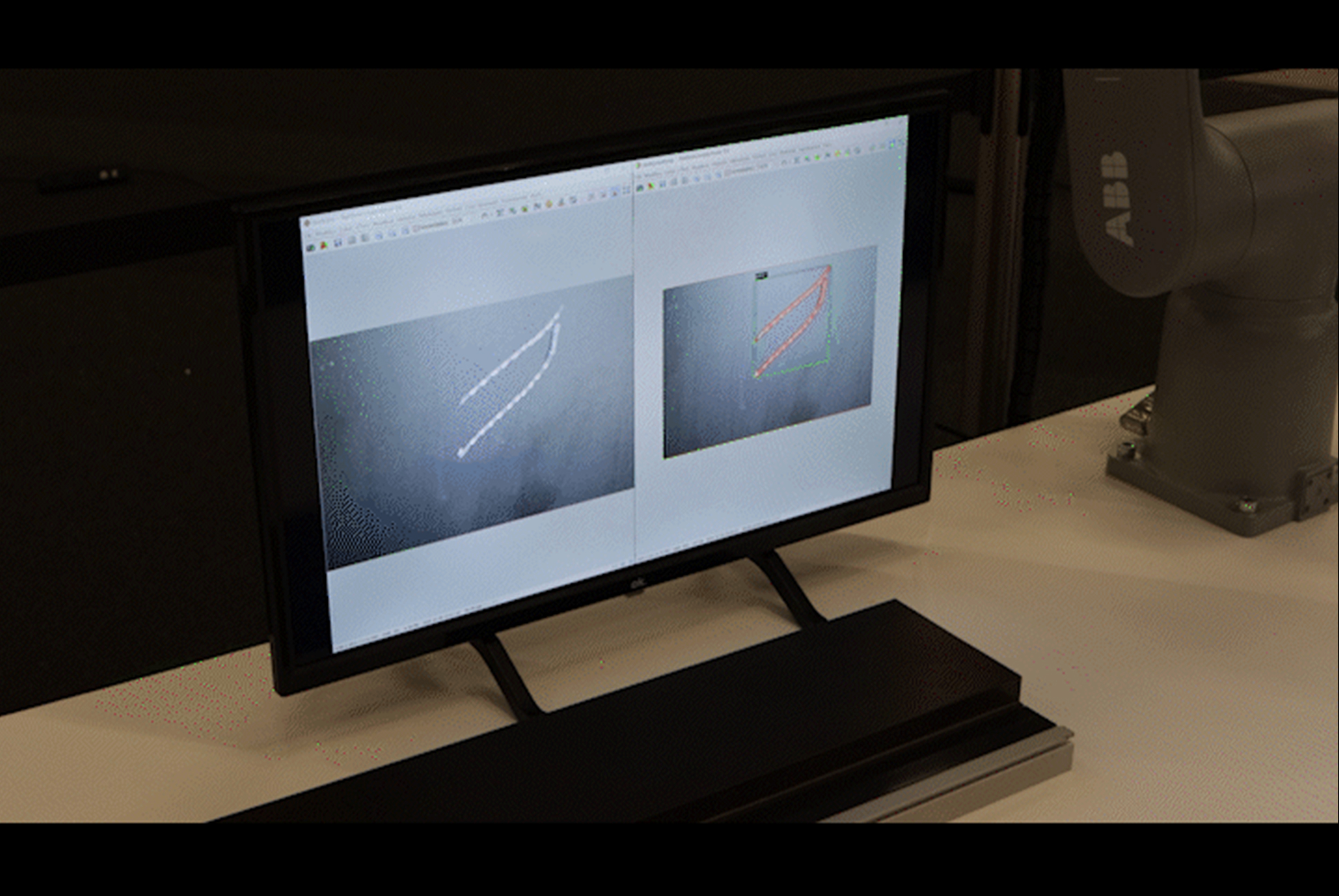

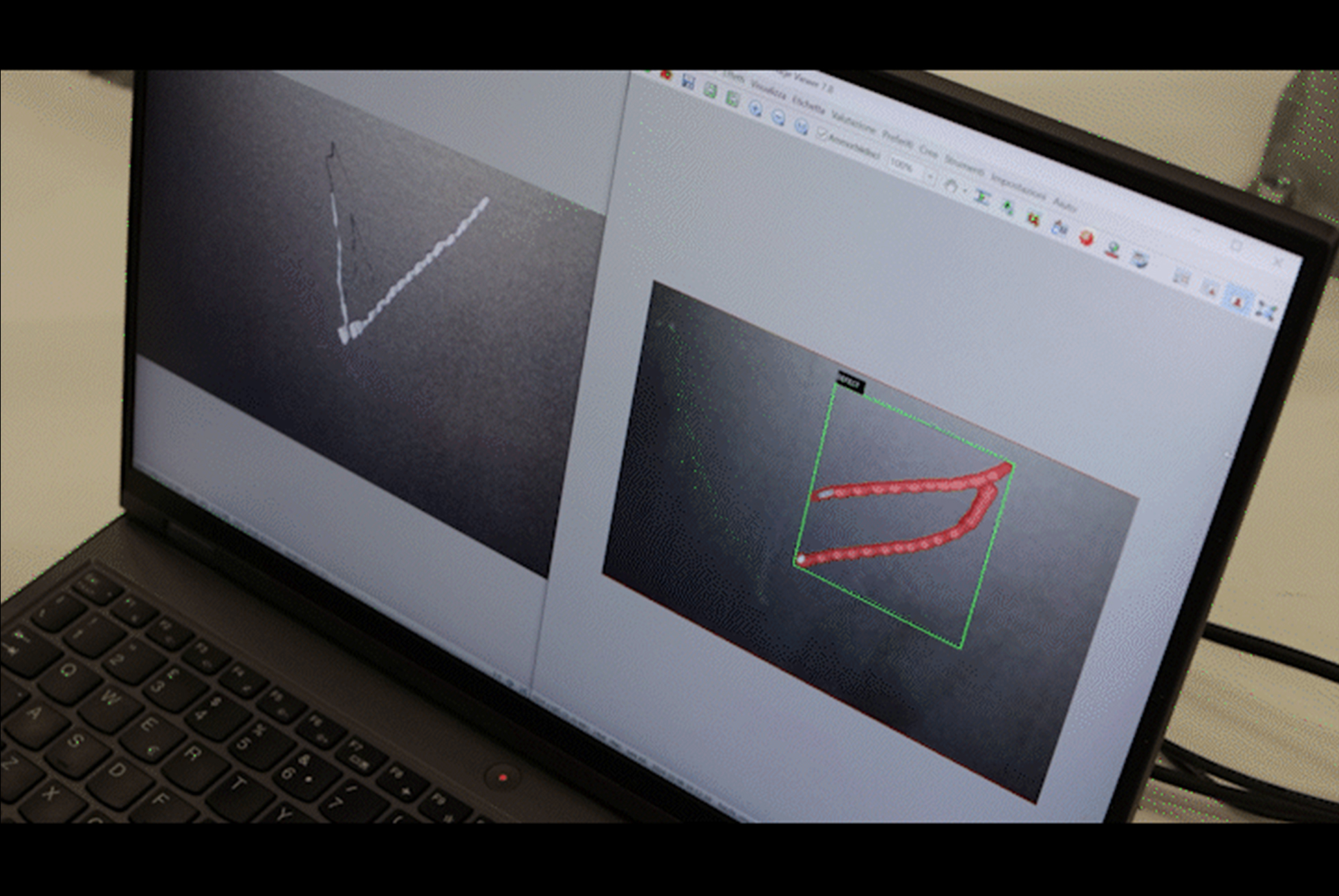

The system captures images of components using industrial cameras mounted on robotic arms.

The developed algorithm, based on semantic segmentation models, analyzes the data to detect defects such as scratches, dents, or cracks.

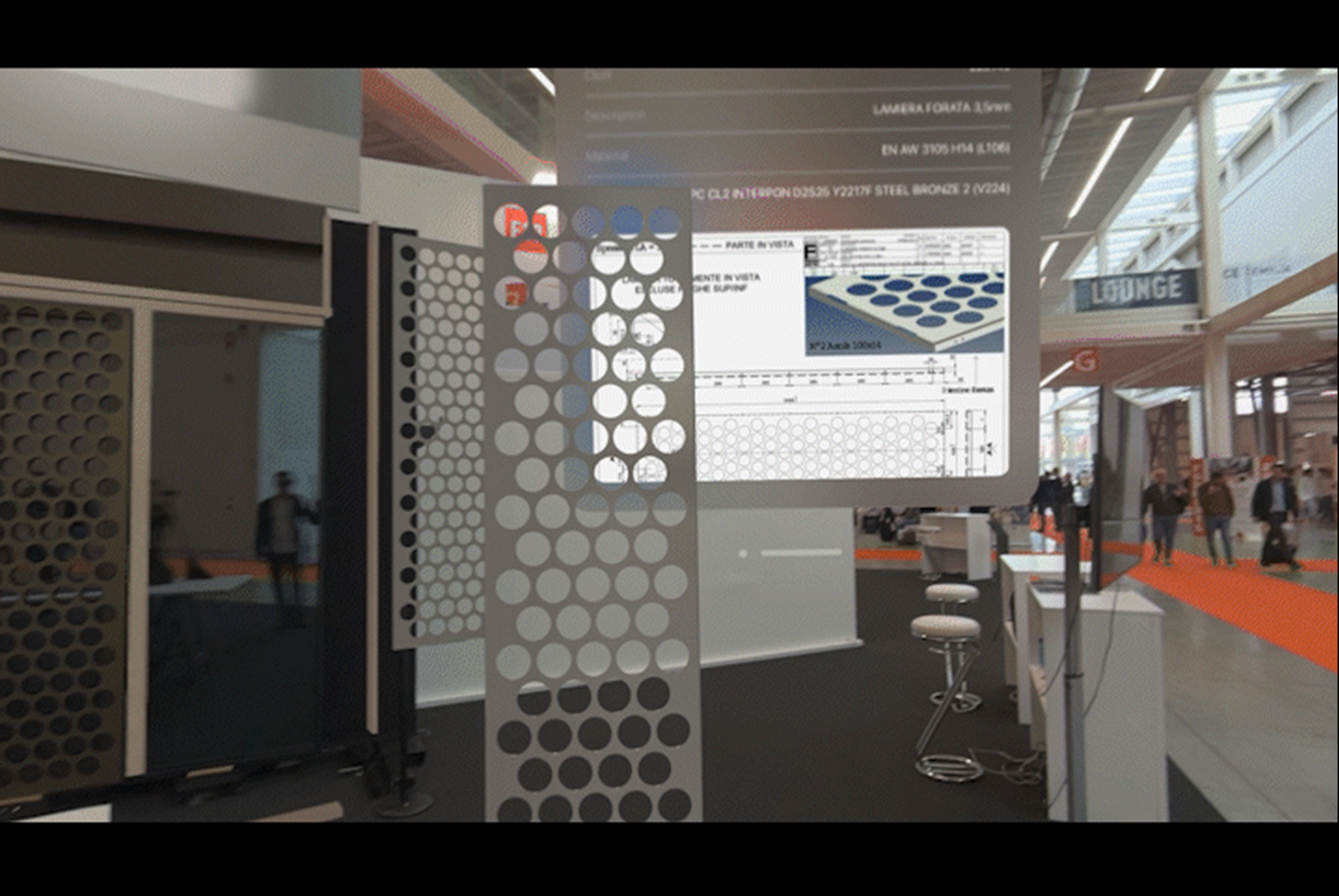

Operators, through Apple Vision Pro headset, view annotations directly on the components. Additionally, an immersive environment accessible through a virtual portal allows for remote, real-time site inspections.

The prototype demonstrates a significant reduction in inspection times and improved defect traceability compared to manual quality control.

The use of mixed reality simplifies communication between production and assembly. The system enhances perceived quality and accelerates on-site operations.

space

MATERIALS

Aluminum | Digital Materials

PROCESSES

Robotic Defect Detection | Artificial Intelligence & Machine Learning | Vision System | Prefabrication and Modular construction | Mixed Reality

DESIGNS

Kit-of-Parts Modular Systems

space

ROLES

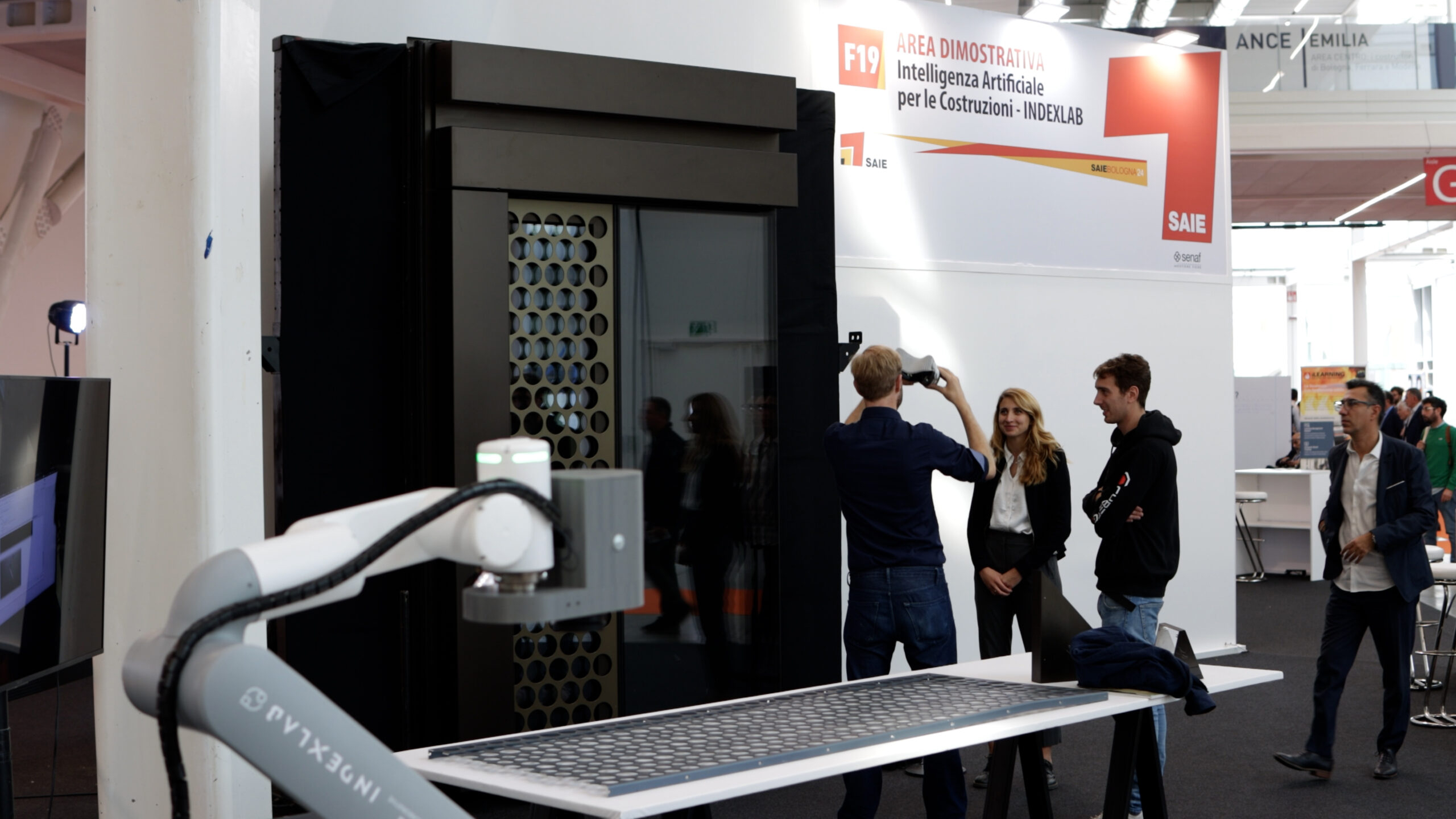

Indexlab prototyped Deetekt, a system for early-stage quality control in curtain wall construction. The team developed an AI-driven workflow that combines computer vision with immersive technologies to automatically detect anomalies during the material procurement phase.

STAKEHOLDERS

LOCATION

First exhibited at SAIE Fair in Bologna, Italy

YEAR

2024

space