LOUVEN

AI-driven system automating the design-to-fabrication workflow for complex architectural shapes.

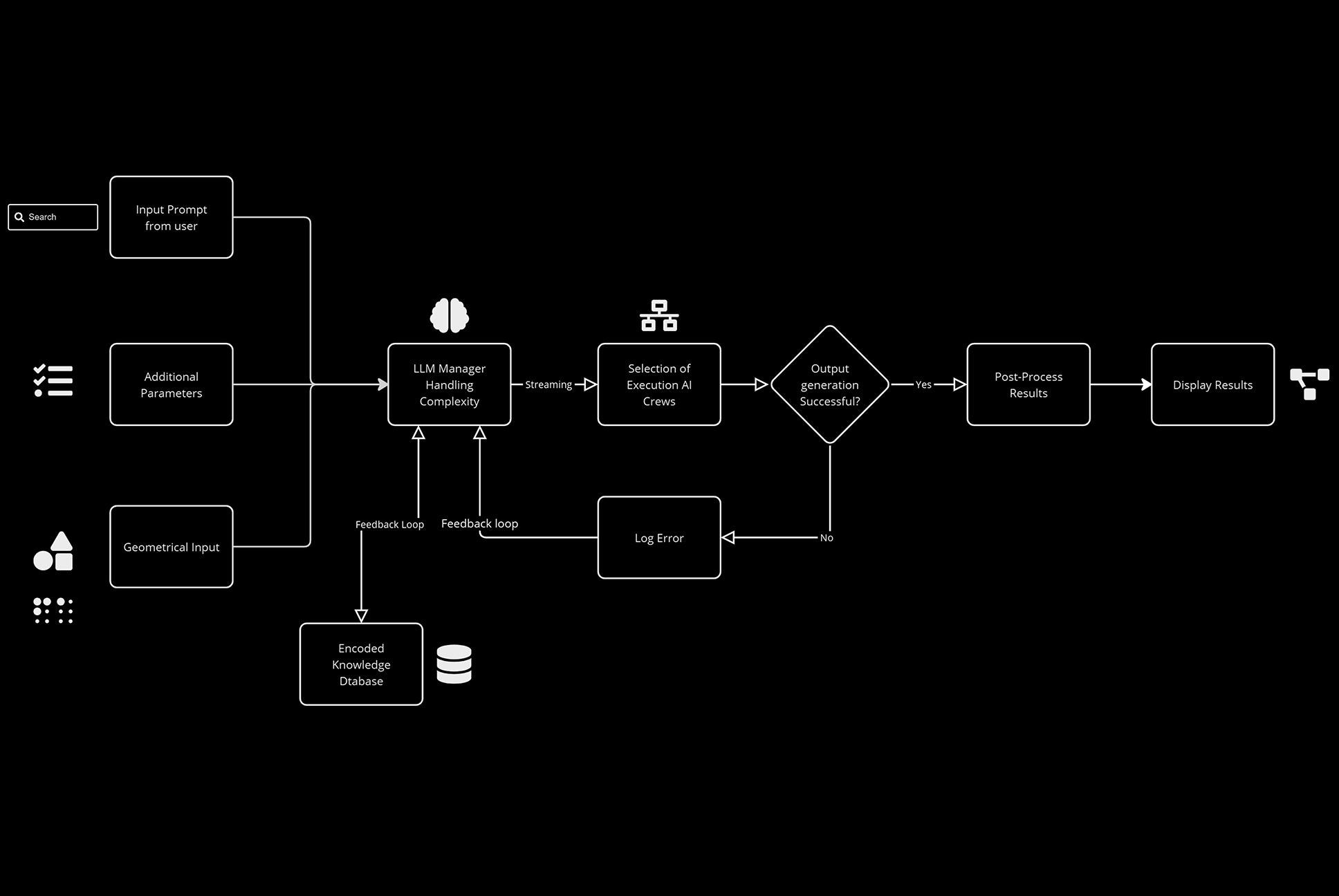

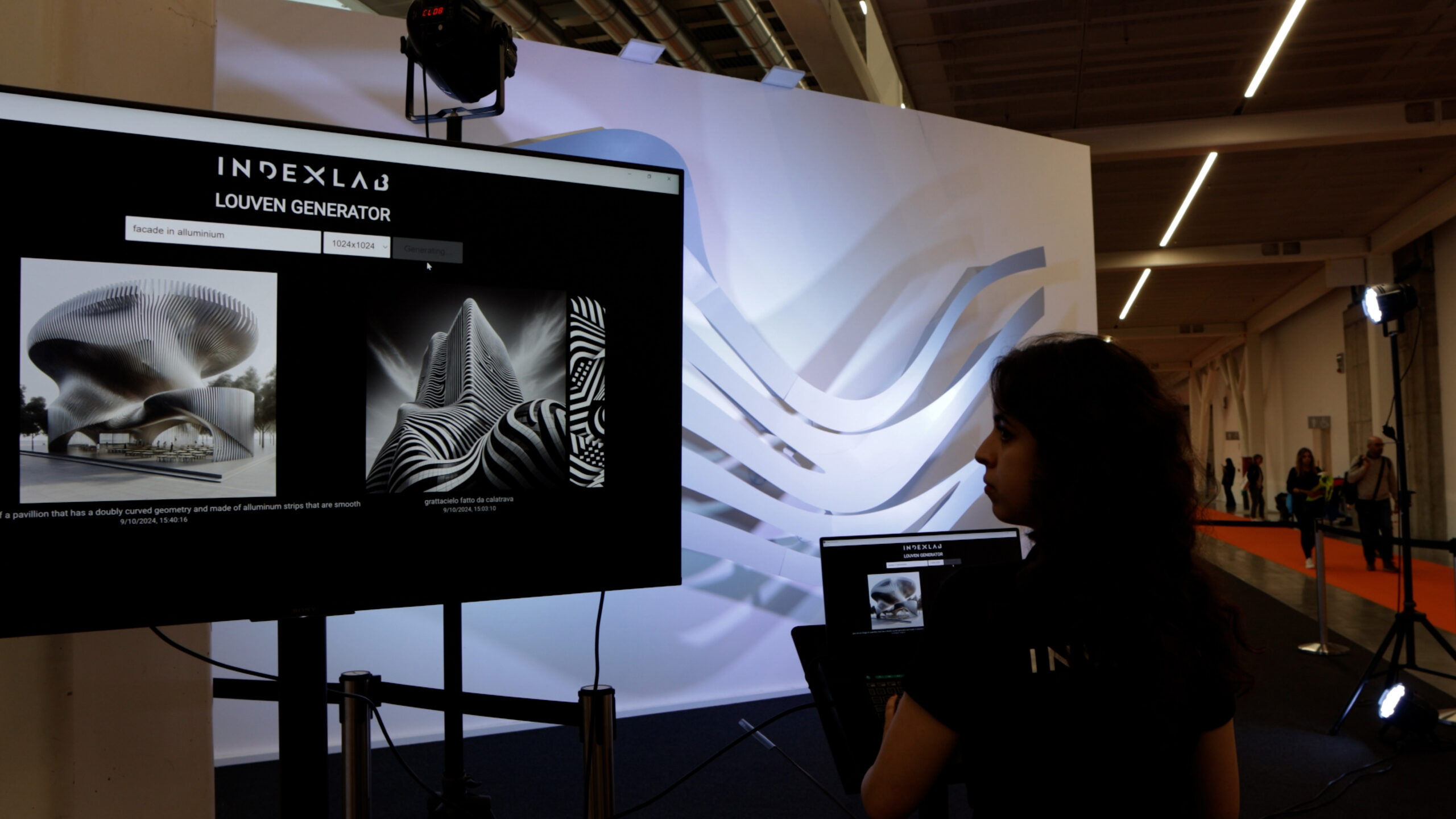

Louven is an AI-driven computational fabrication system that automates the design-to-manufacturing workflow, allowing for the rapid generation of complex architectural surfaces. By integrating Large Language Models (LLMs) with multimodal artificial intelligence, Louven enables designers to create fabrication-ready parametric definitions using text inputs. The system automatically incorporates manufacturing constraints, ensuring all outputs are ready for CNC cutting, bending, and welding.

LOUVEN simplifies computational fabrication by reducing reliance on manual scripting and specialized parametric modeling expertise. Automating the design-to-production pipeline it eliminates time-consuming iterations and ensures that all outputs are CNC-ready for efficient manufacturing.

One of the primary challenges is generating manufacturable geometries that align with both material properties and production constraints.

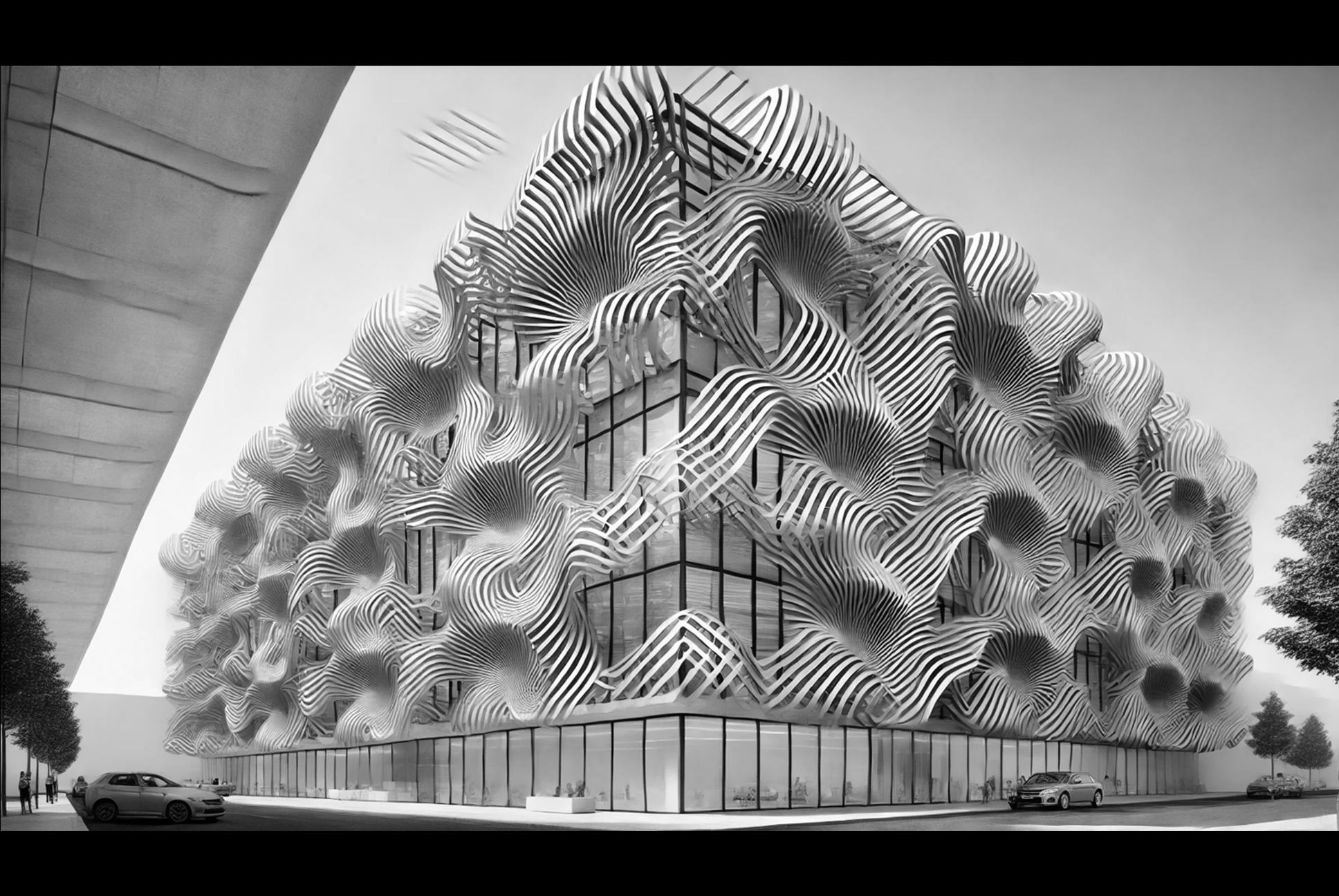

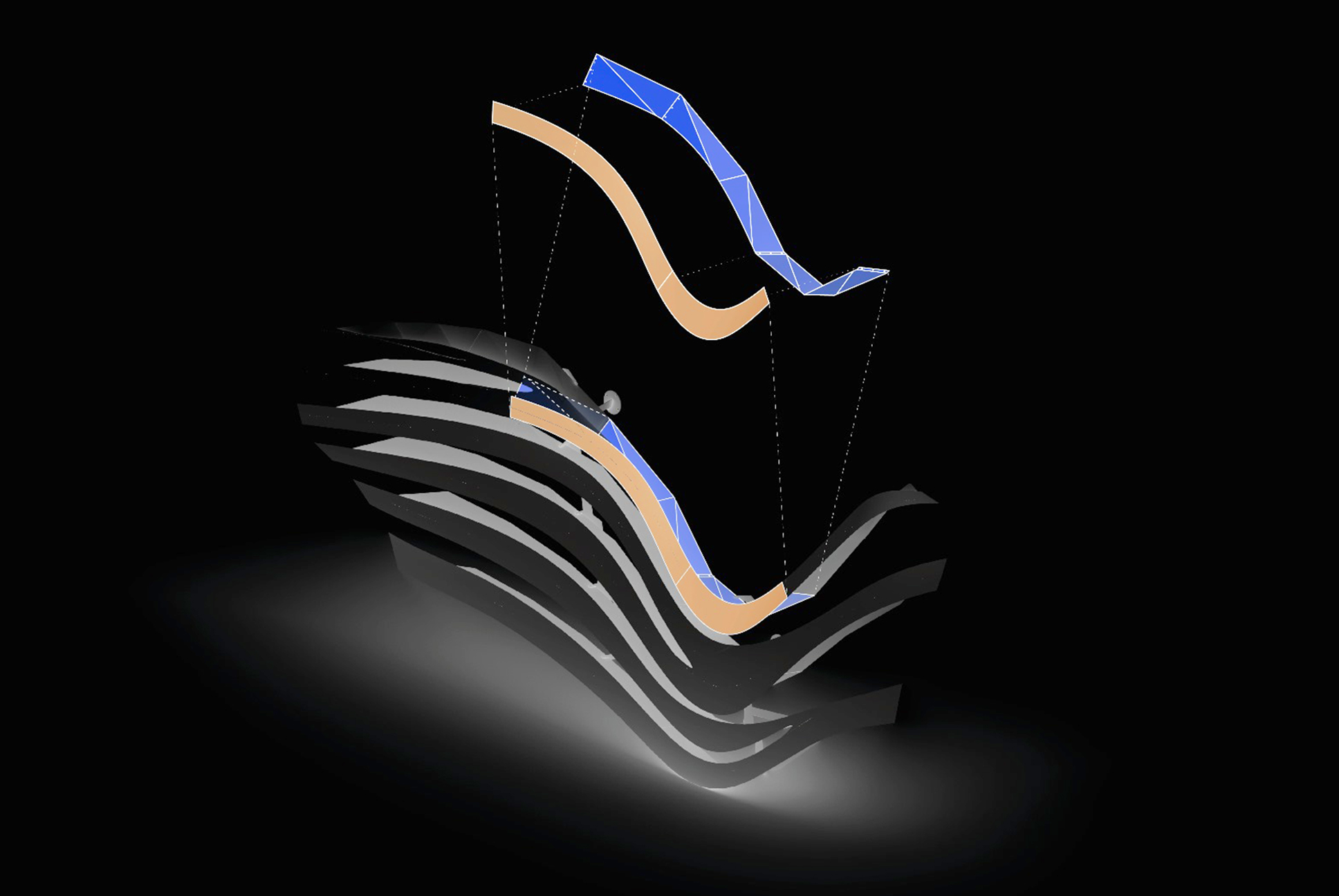

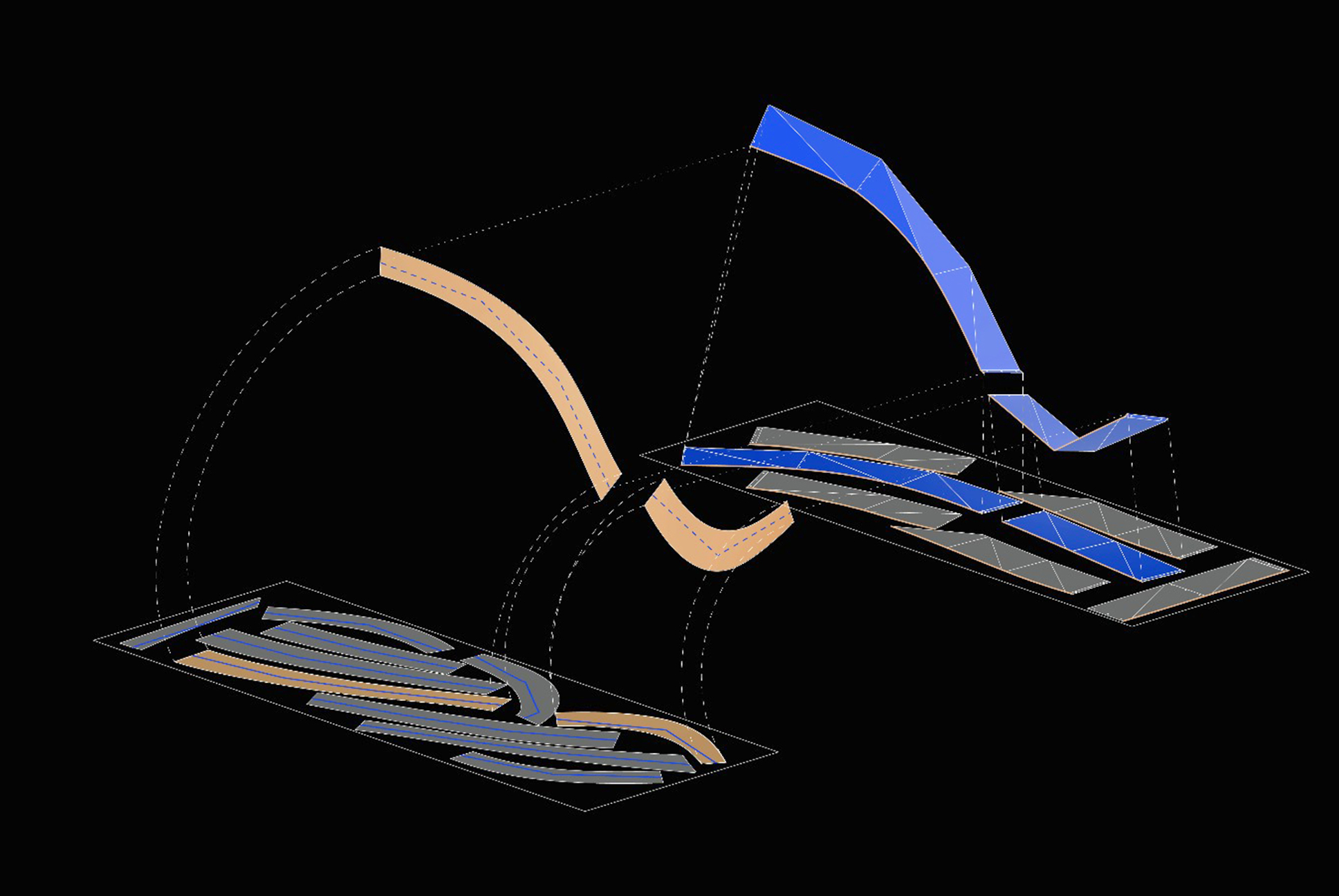

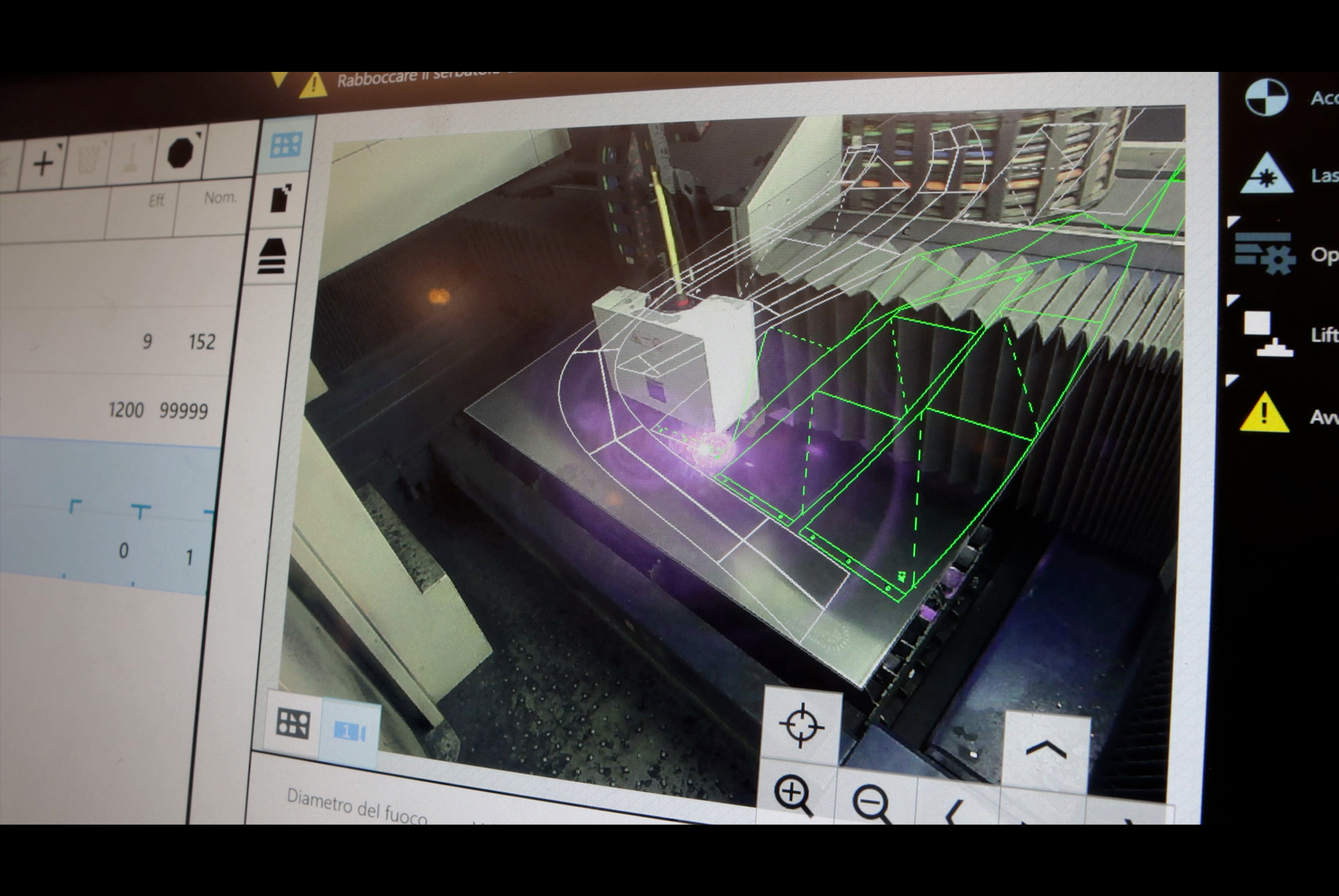

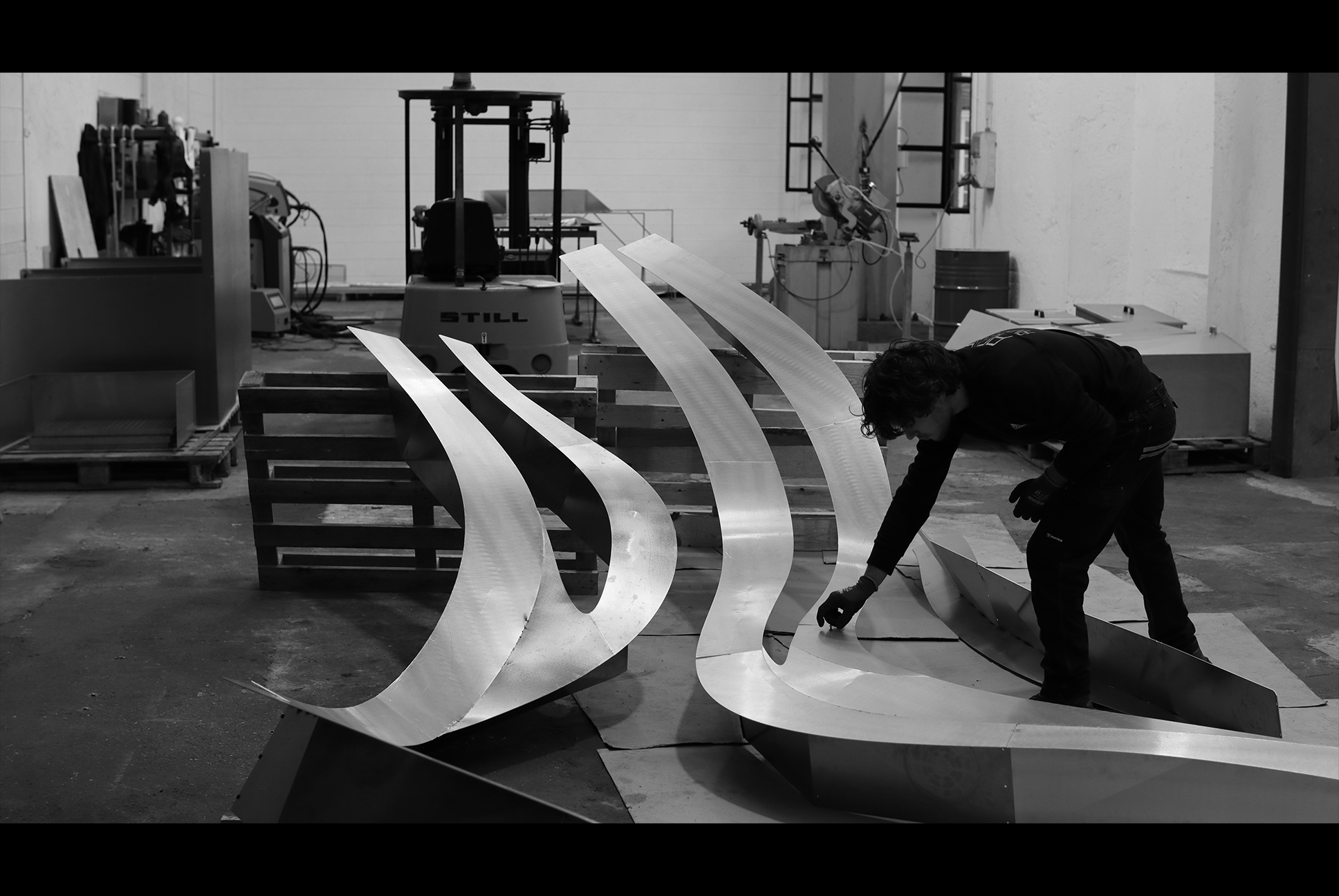

LOUVEN’s LLM-based system translates conceptual inputs into parametric models embedded with fabrication constraints. These models define stripe-based patterns that shape double-curved surfaces, reinforced by a T-system for structural stability. Once generated, the parametric models are processed for manufacturing. The system employs CNC cutting, bending, and laser welding to process 2mm-thick aluminum panels, streamlining assembly without the need for manual adjustments. AI-generated toolpaths integrate bend angles and joint tolerances directly into the fabrication process.

The LOUVEN case study has been tested on customized shading elements and façade systems, demonstrating its ability to streamline the design-to-fabrication process. By reducing the need for manual parameter adjustments, the system lowers technical barriers and simplifies the transition from concept to production. Through intelligent segmentation of curved elements, material usage is optimized, minimizing waste while maintaining geometric accuracy. Structural precision is improved as CNC bending and welding processes ensure that each component aligns with predefined fabrication constraints.

MATERIALS

Aluminum | Digital Materials

PROCESSES

Laser Cutting | Sheet Plate Bending | Laser Welding | Artificial Intelligence & Machine Learning

DESIGNS

Triangulation | Band Strips | Lofting | AI Image Generation

ROLES

Indexlab developed the core workflow of LOUVEN, integrating LLMs with multimodal AI to enable text-based generation of fabrication-ready parametric models. Indexlab also defined the system's architectural logic and material constraints, ensuring outputs are directly compatible with CNC cutting, bending, and welding processes.

STAKEHOLDERS

LOCATION

First exhibited at SAIE Fair in Bologna, Italy

YEAR

2024

Get in touch!

SAY HELLO

info@indexlab.it

Follow

LINKEDIN

Copyright © 2025 INDEXLAB

All rights reserved