SUPERFRAMEs

A Hybrid Construction Method for Freeform Surfaces via Panel Discretization and Screw Extrusion

Superframe is a construction system that integrates planar panels with 3D-printed thermoplastic frames to realize free-form geometries in a cost-effective, sustainable manner. Leveraging Robotic Additive Moulding (RAM) and tailored discretization strategies, Superframe streamlines fabrication by shifting surface complexity to the printed frames, enabling faster production, reduced material usage, and broad design freedom. Iterative prototypes (v1, v2, v3, and v4) demonstrate the system’s evolution, highlighting how computational design, additive manufacturing, and custom discretization come together to build geometries that meet contemporary demands for resource-conscious and creative architectural solutions.

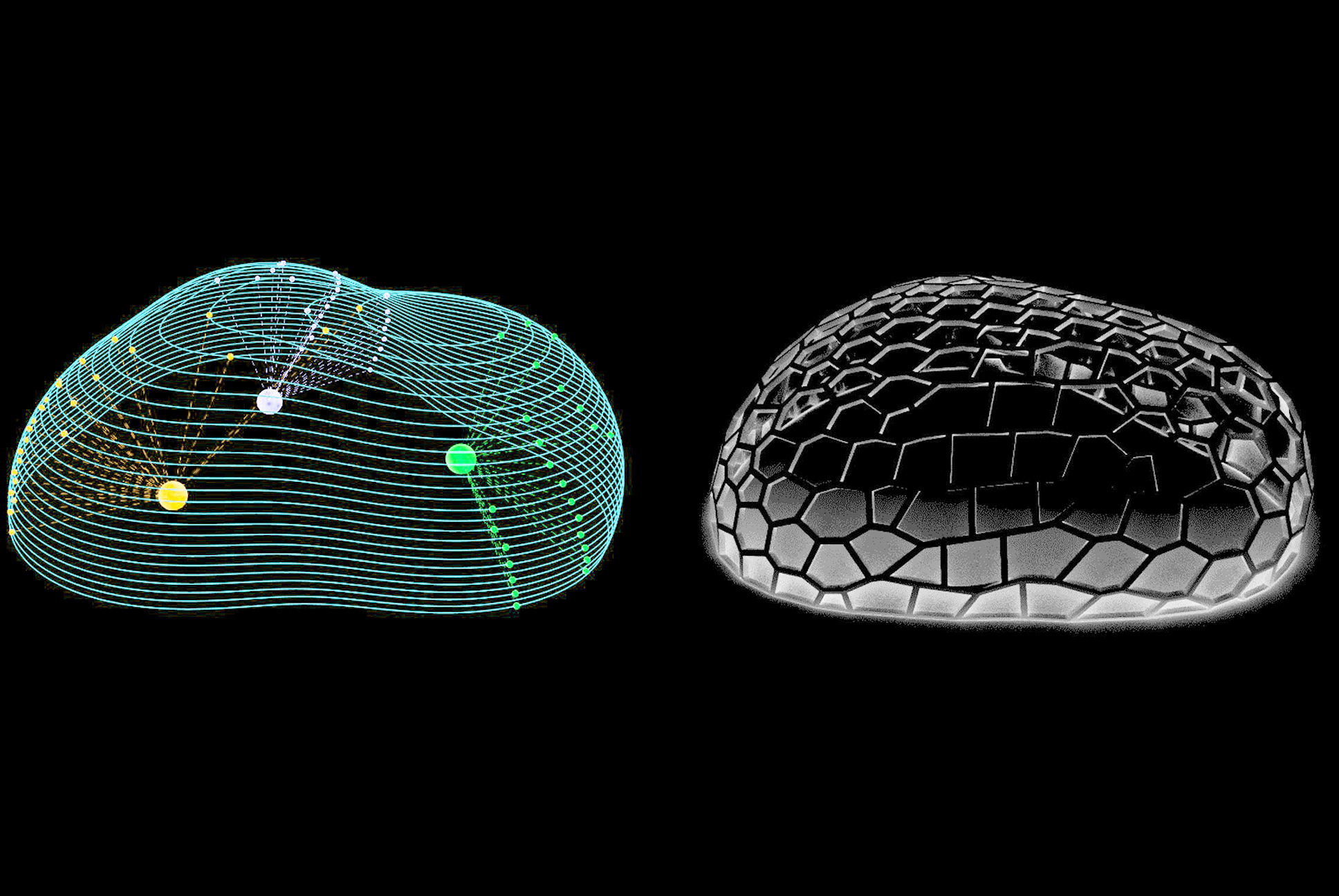

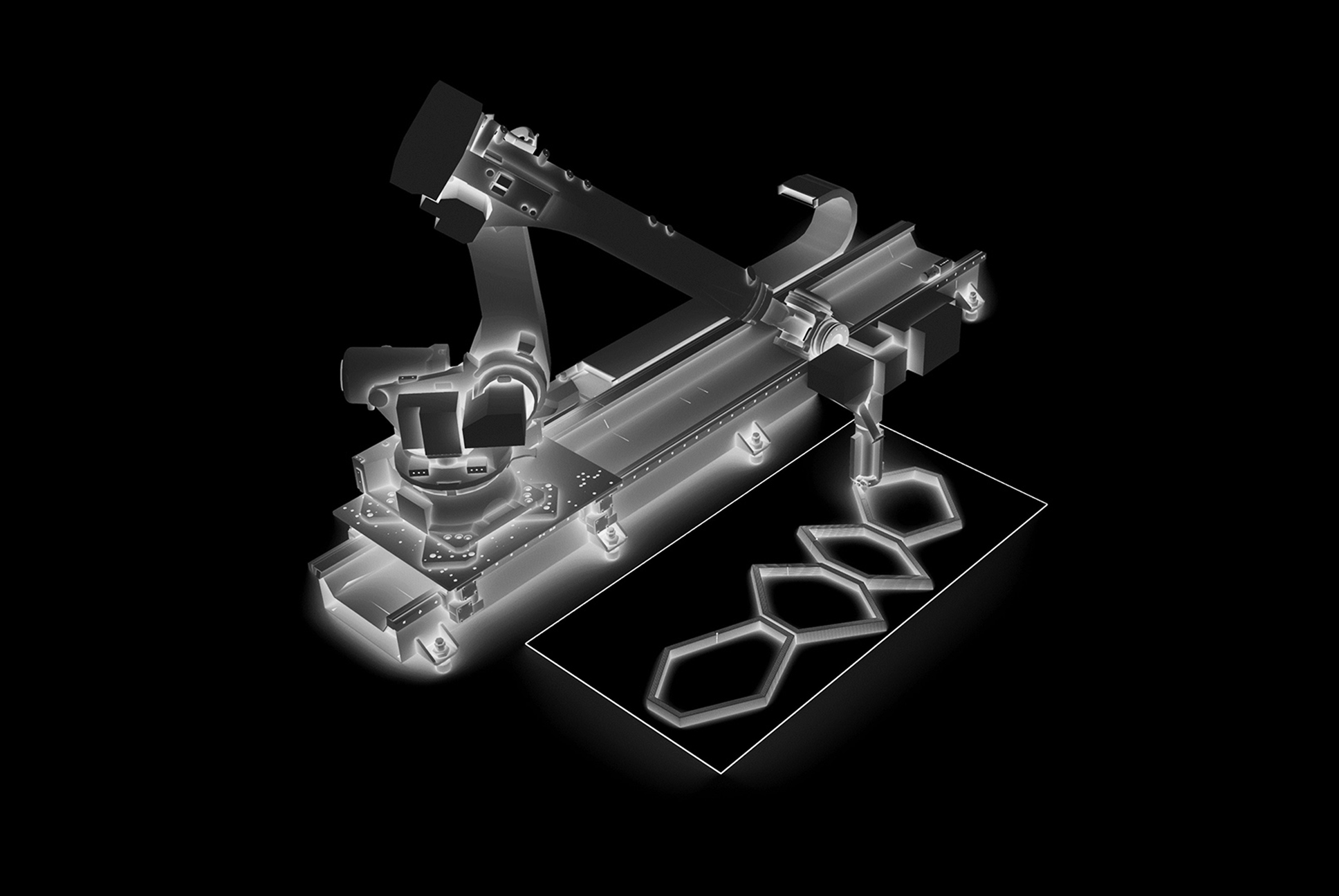

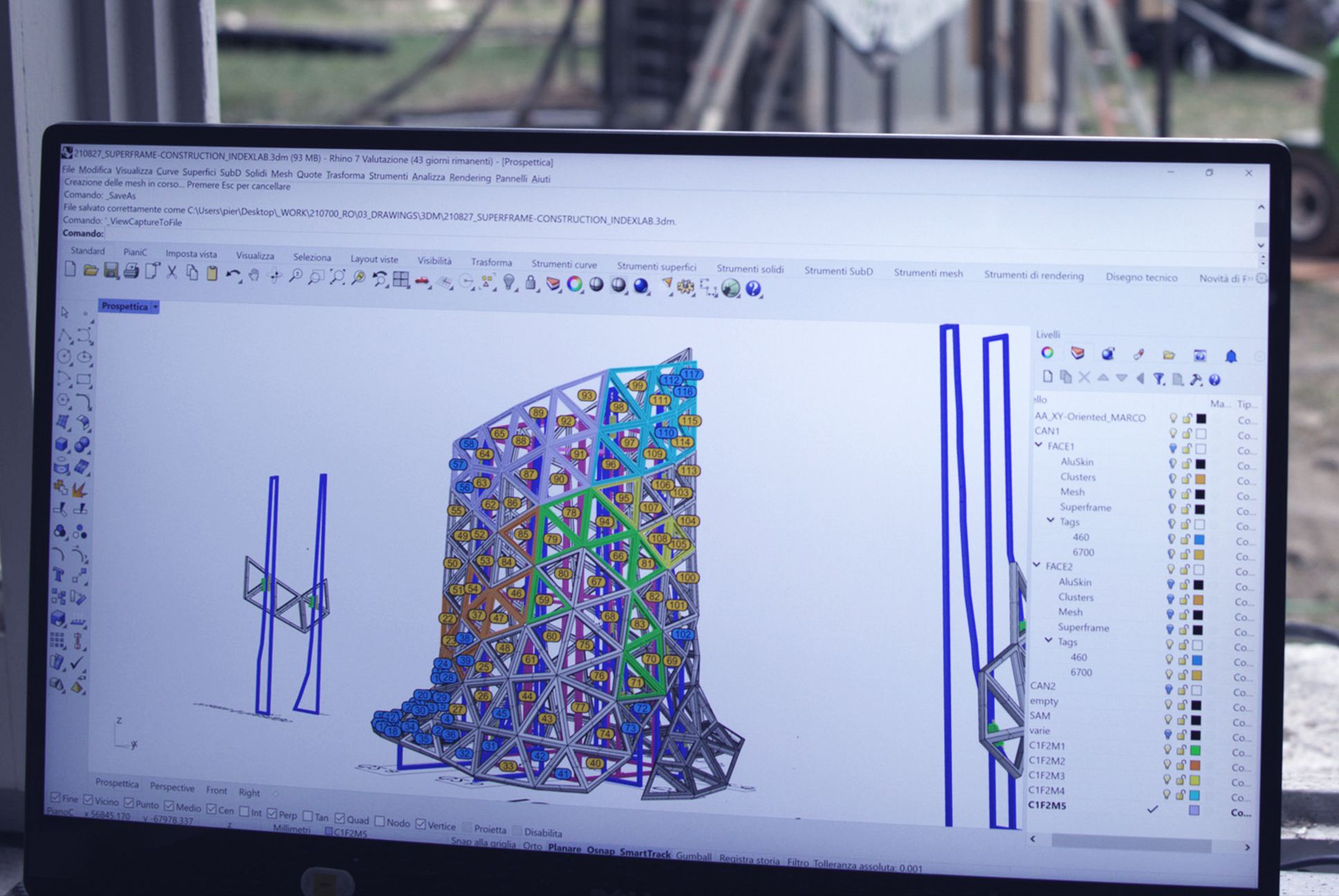

Superframe’s methodology rests on computational design tools and a robotic additive manufacturing process.

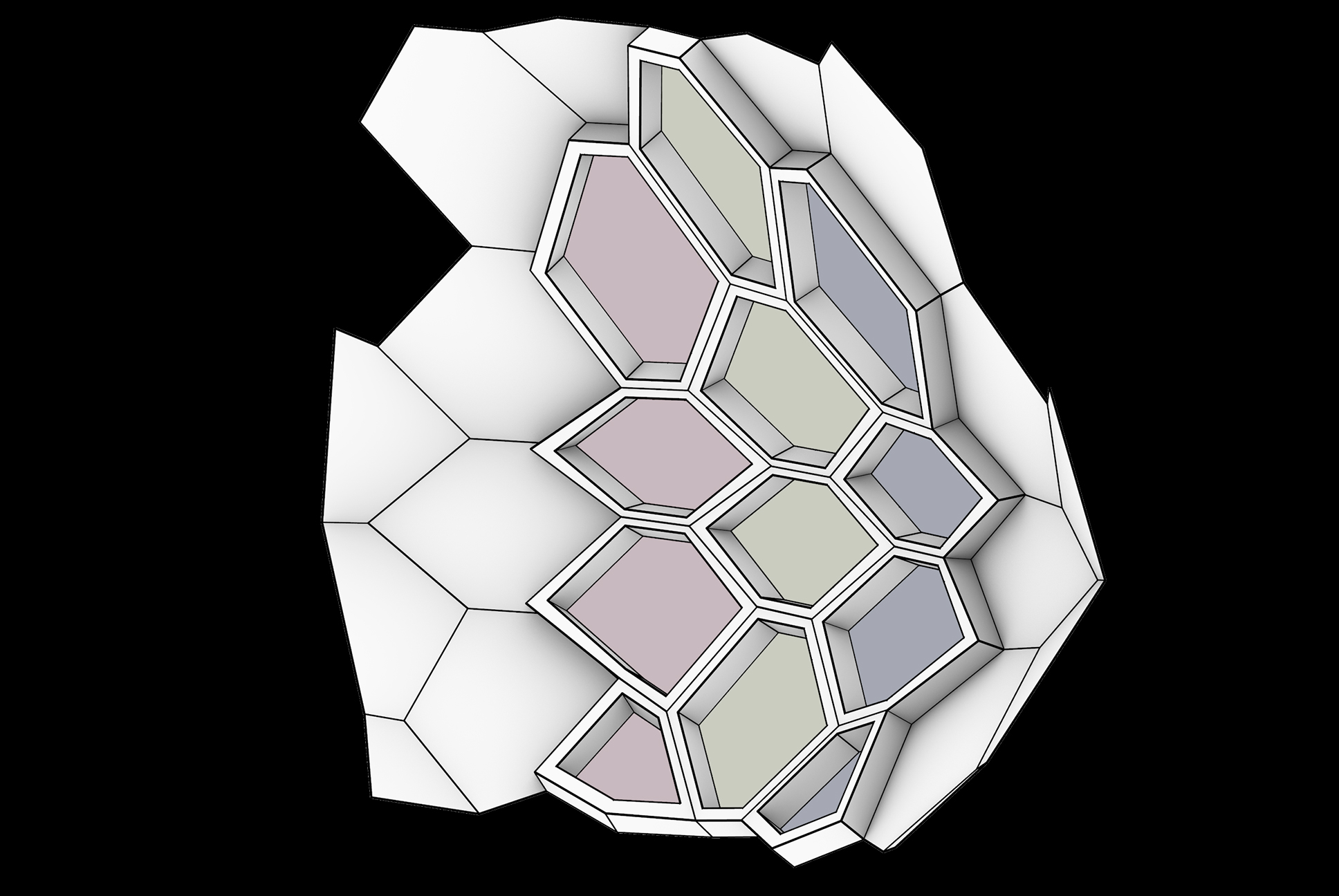

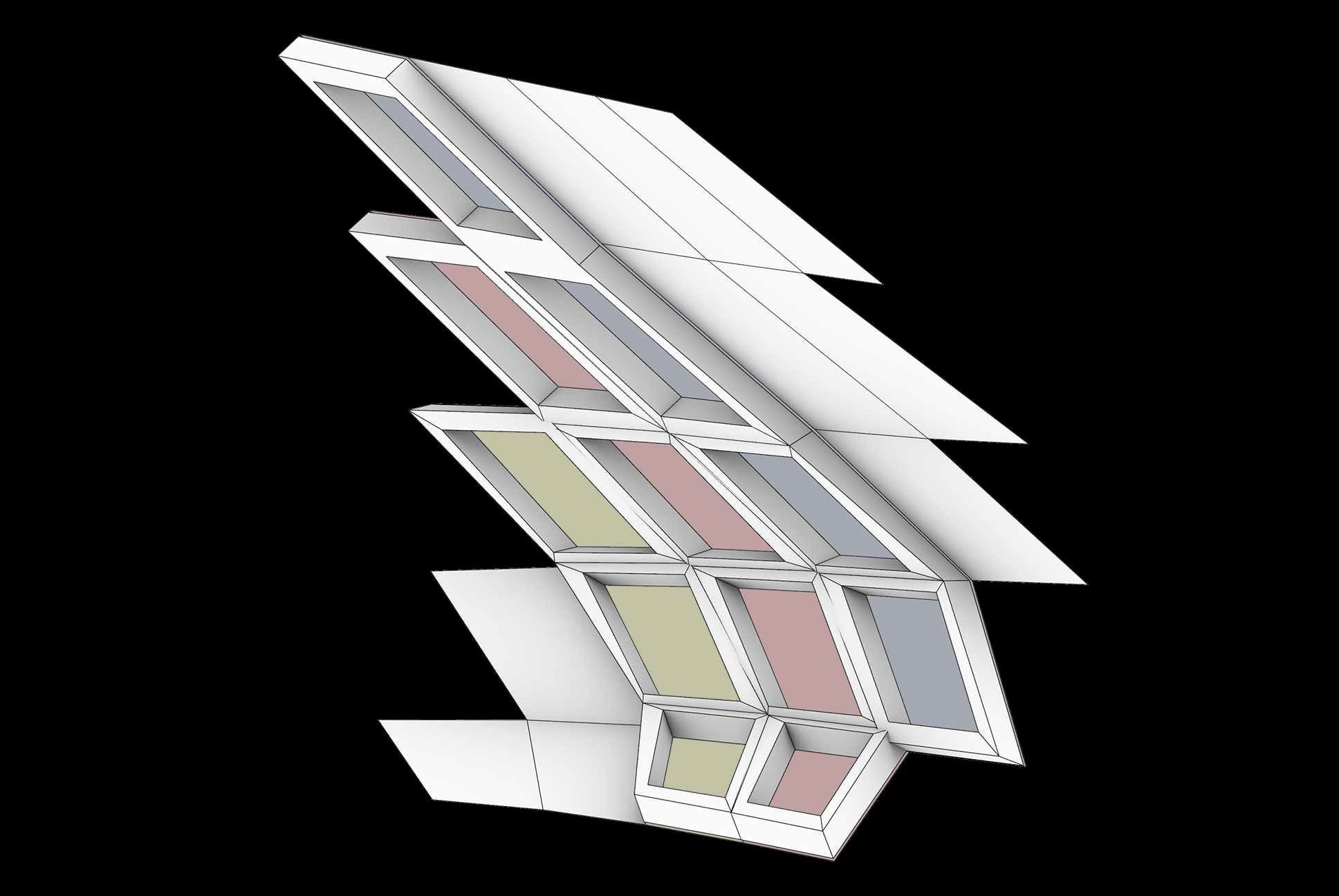

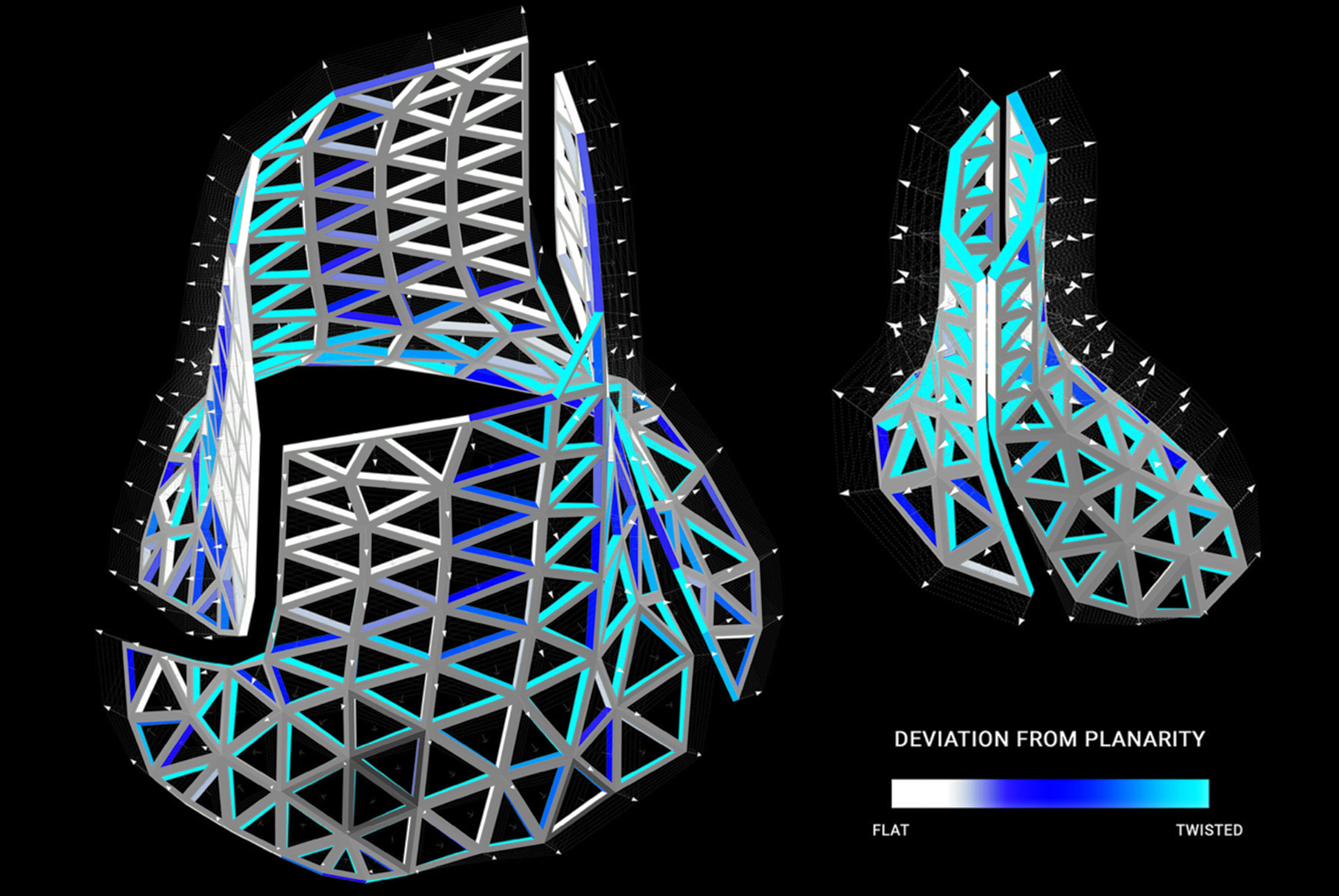

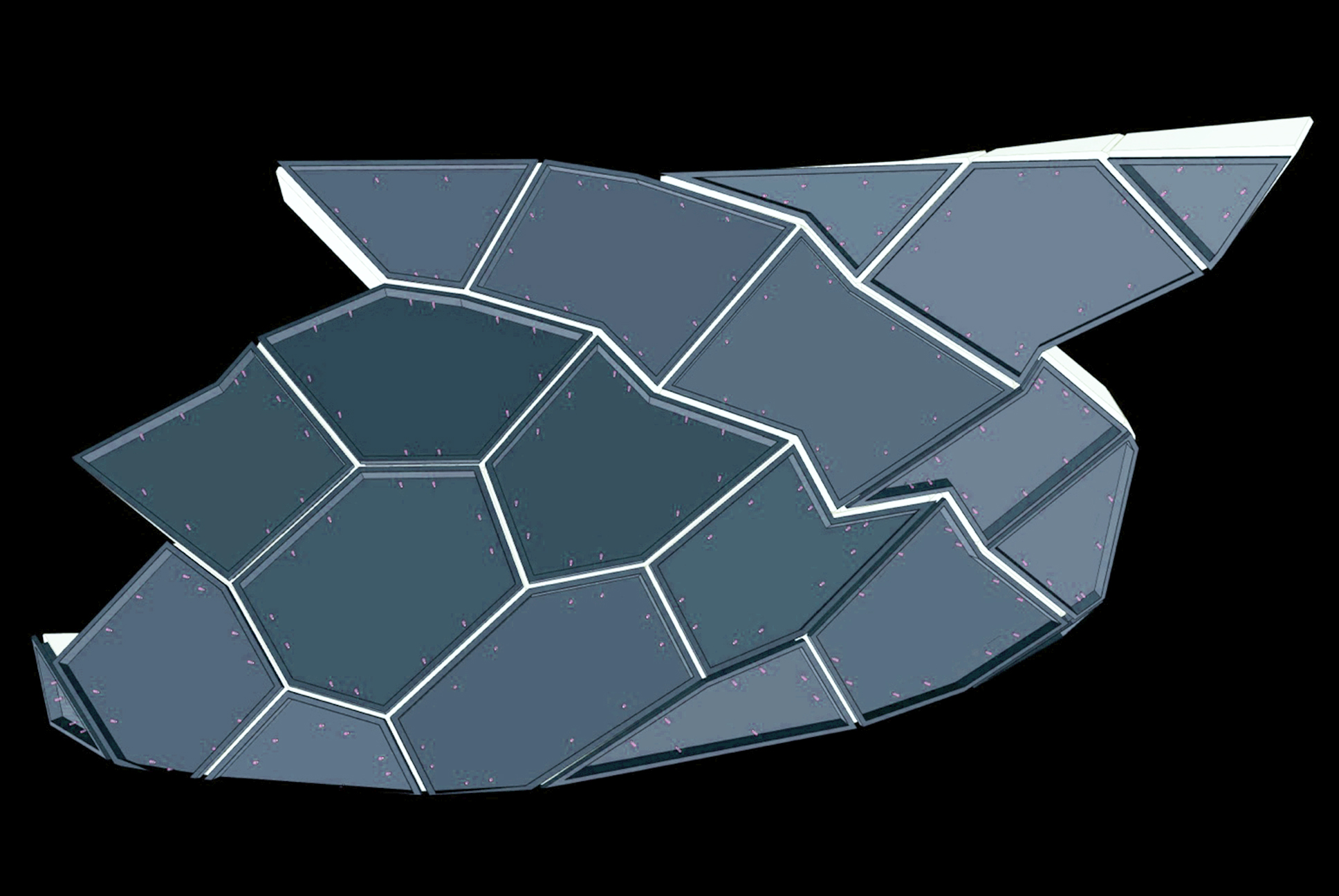

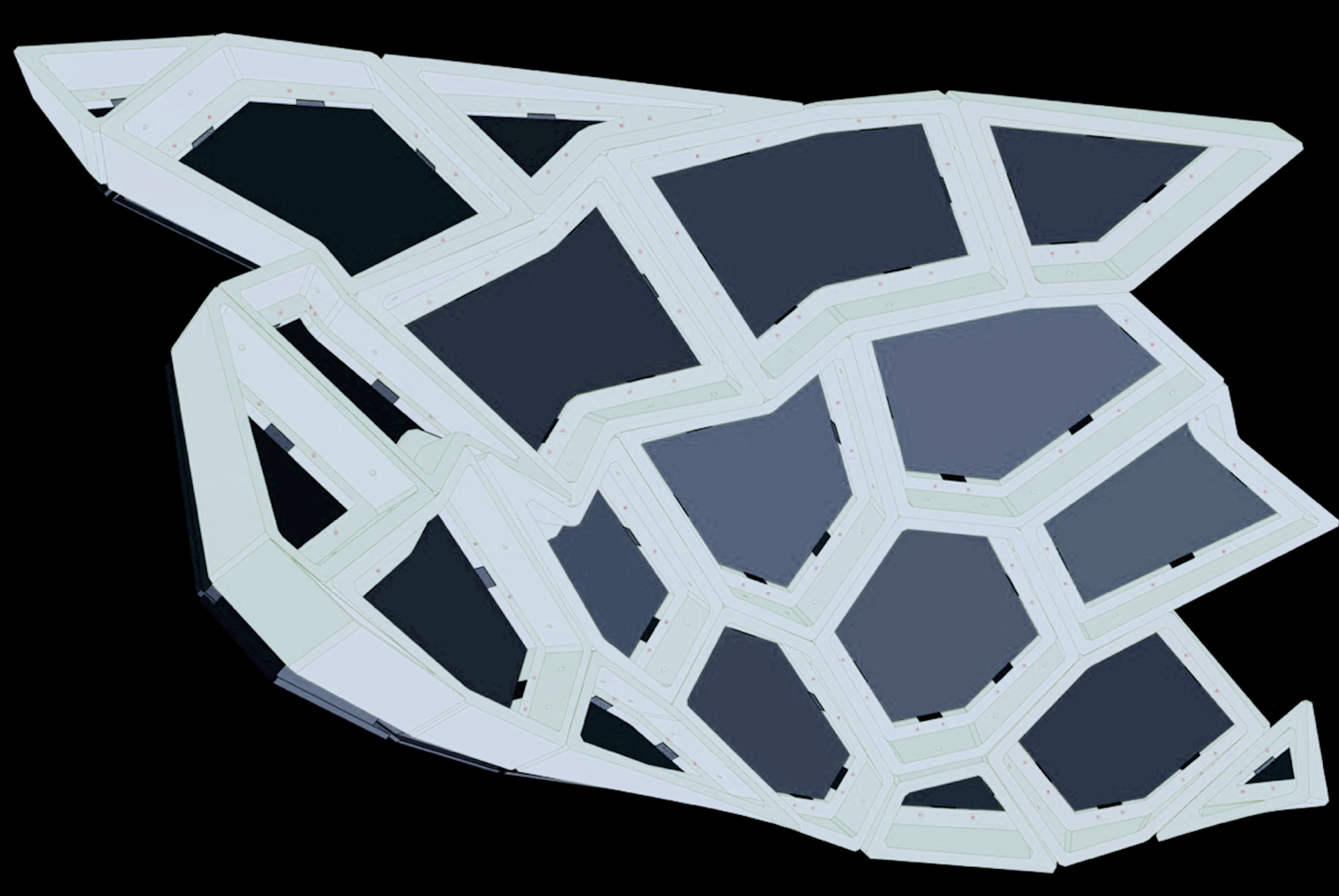

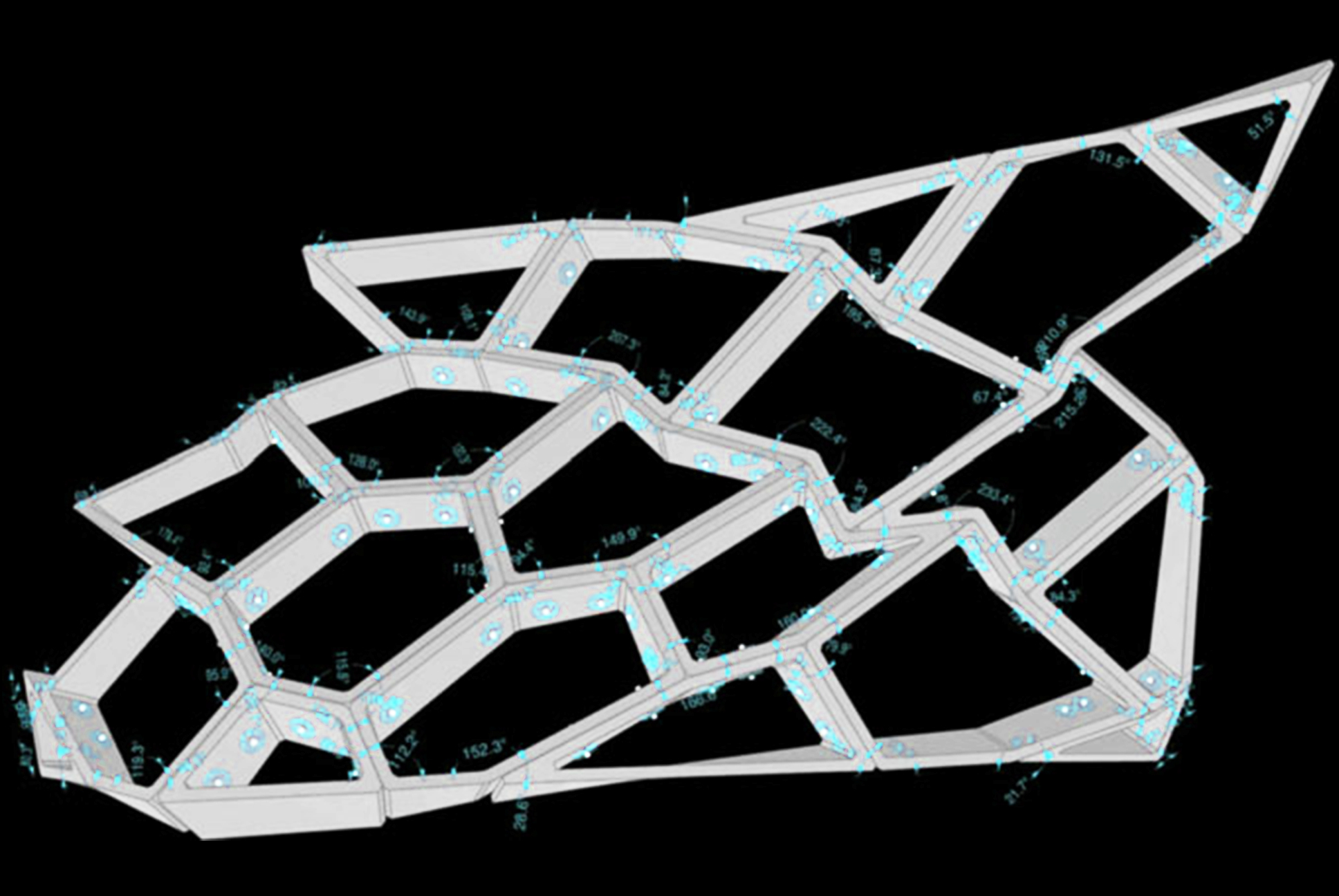

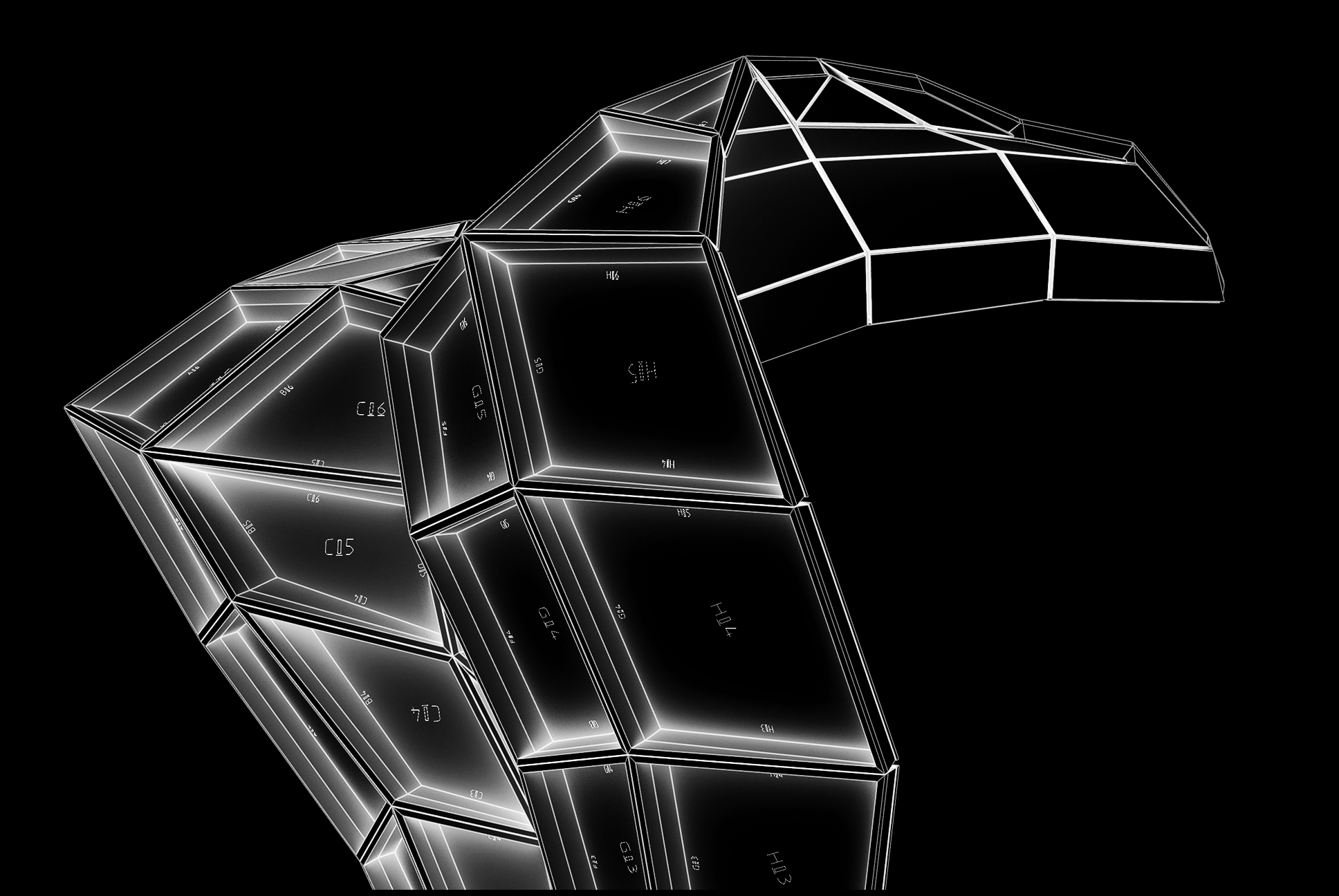

Parametric models break free-form surfaces into planar n-gonal panels (triangles, quadrilaterals, pentagons, hexagons), minimizing geometric deviation from the original double-curved surface.

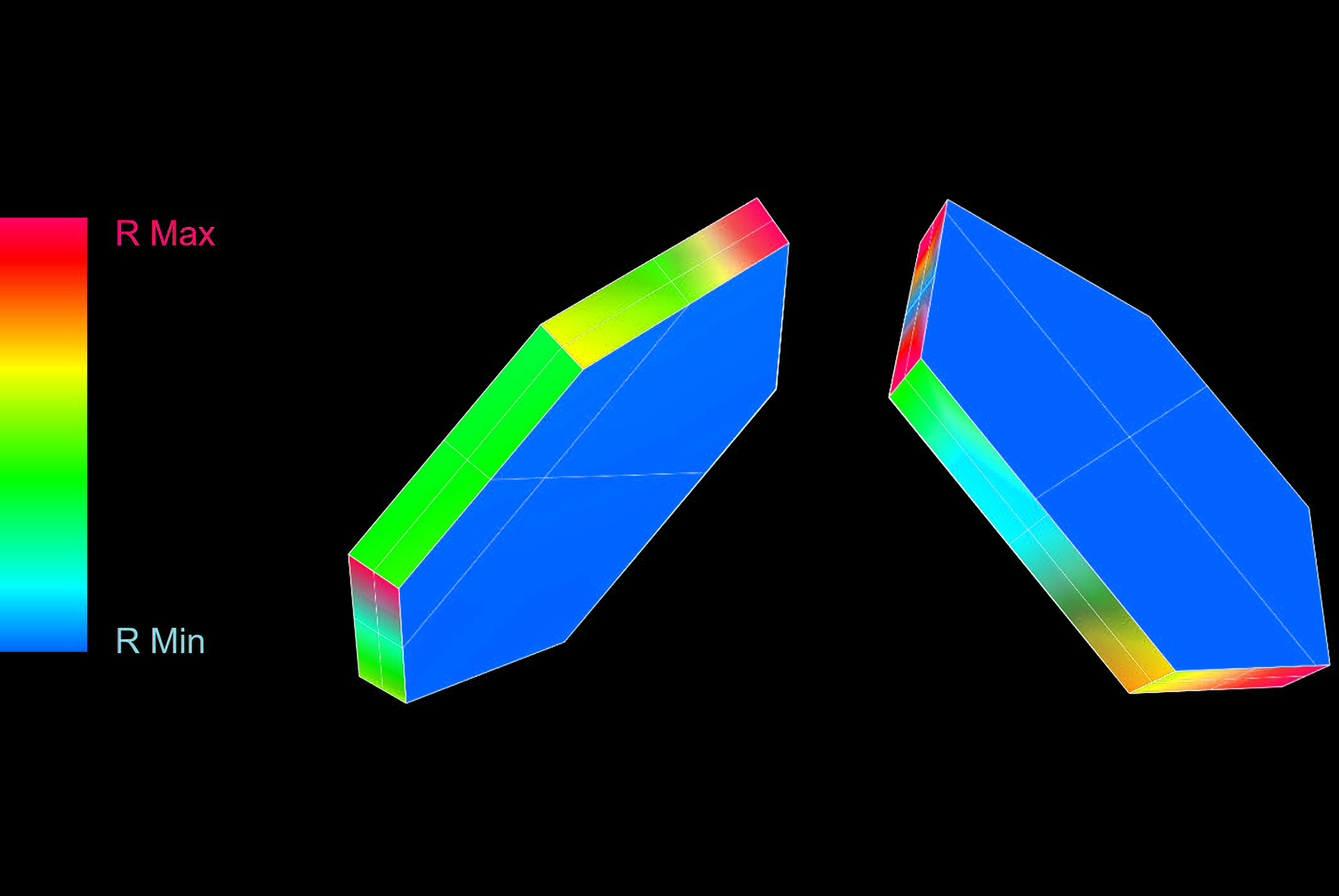

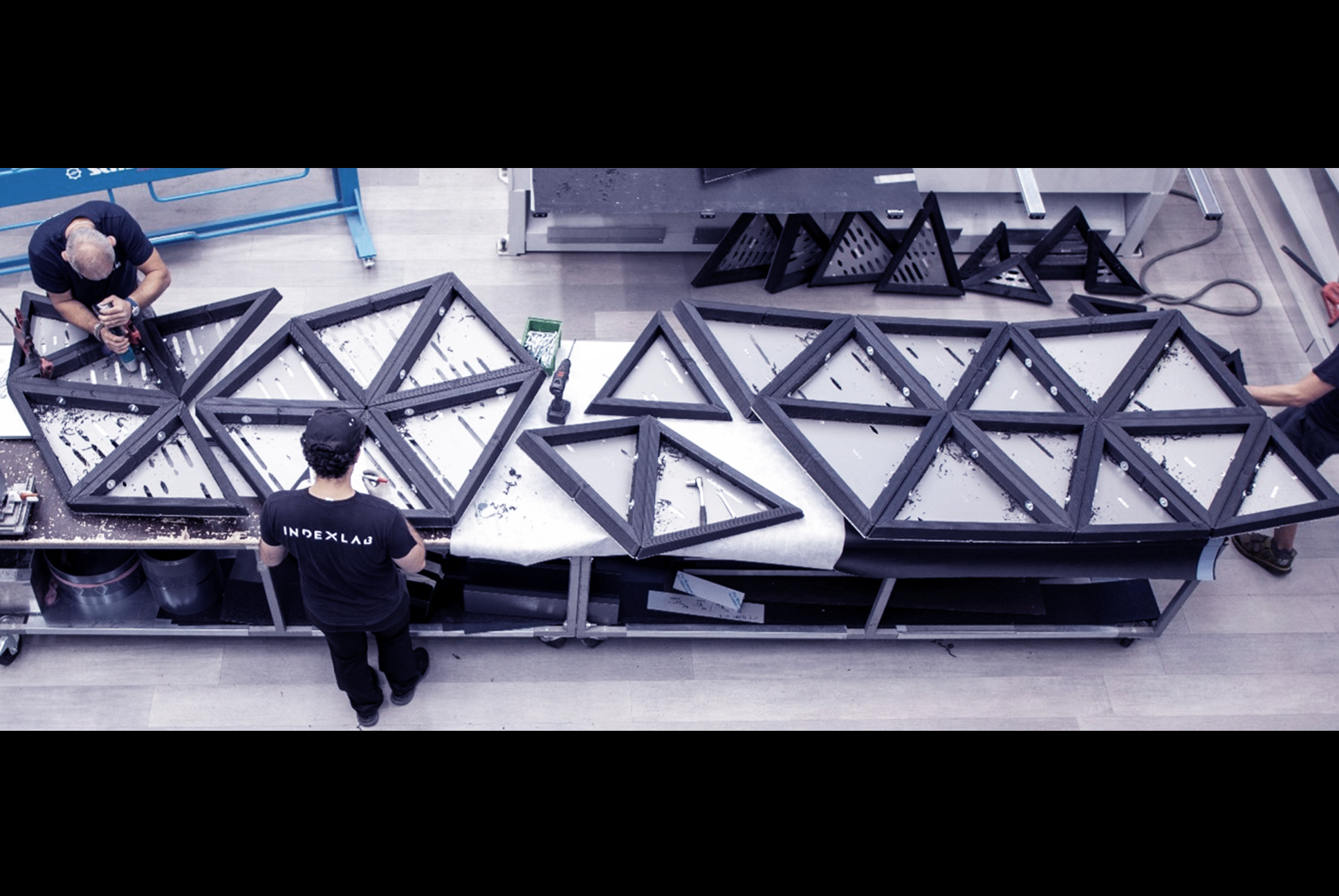

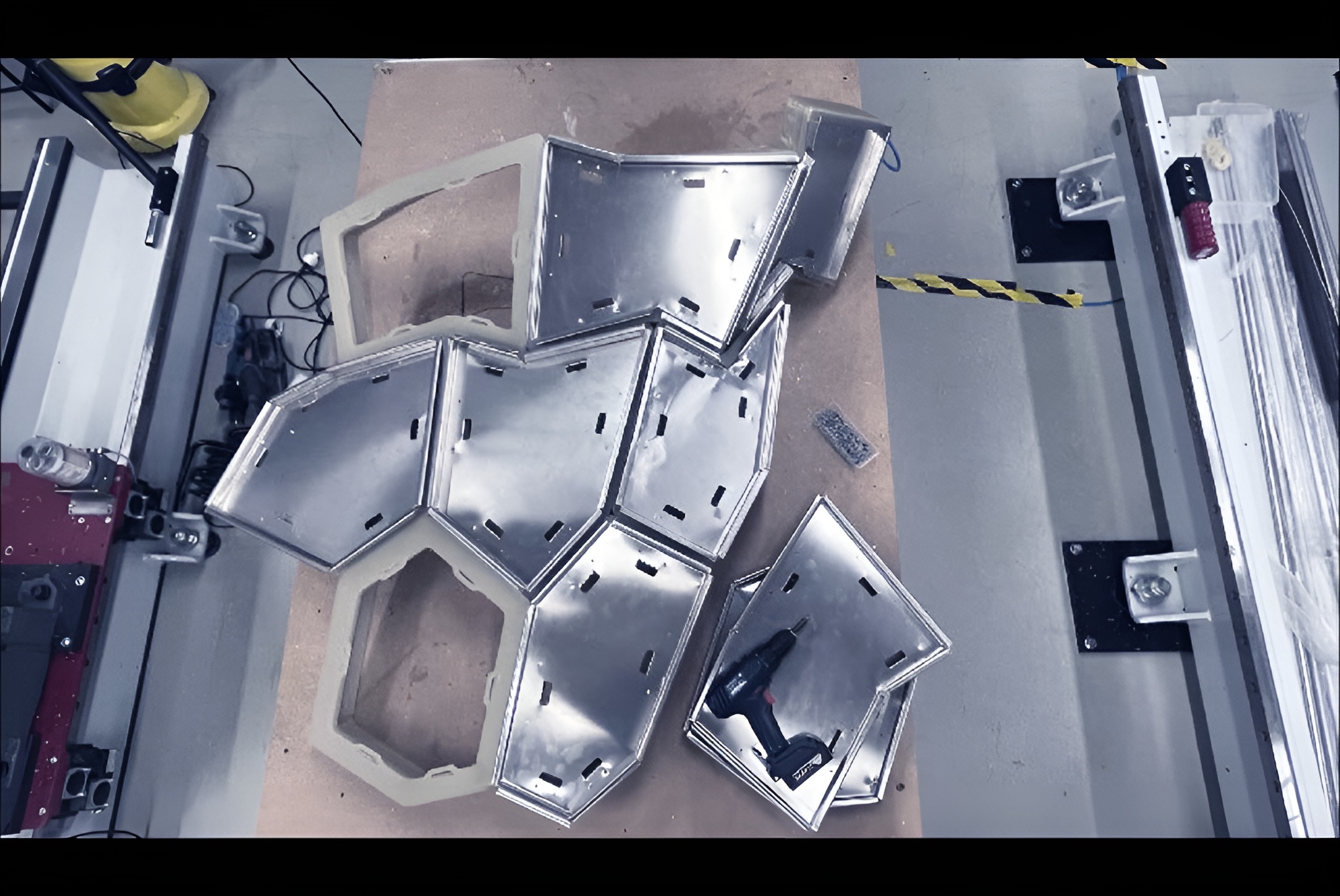

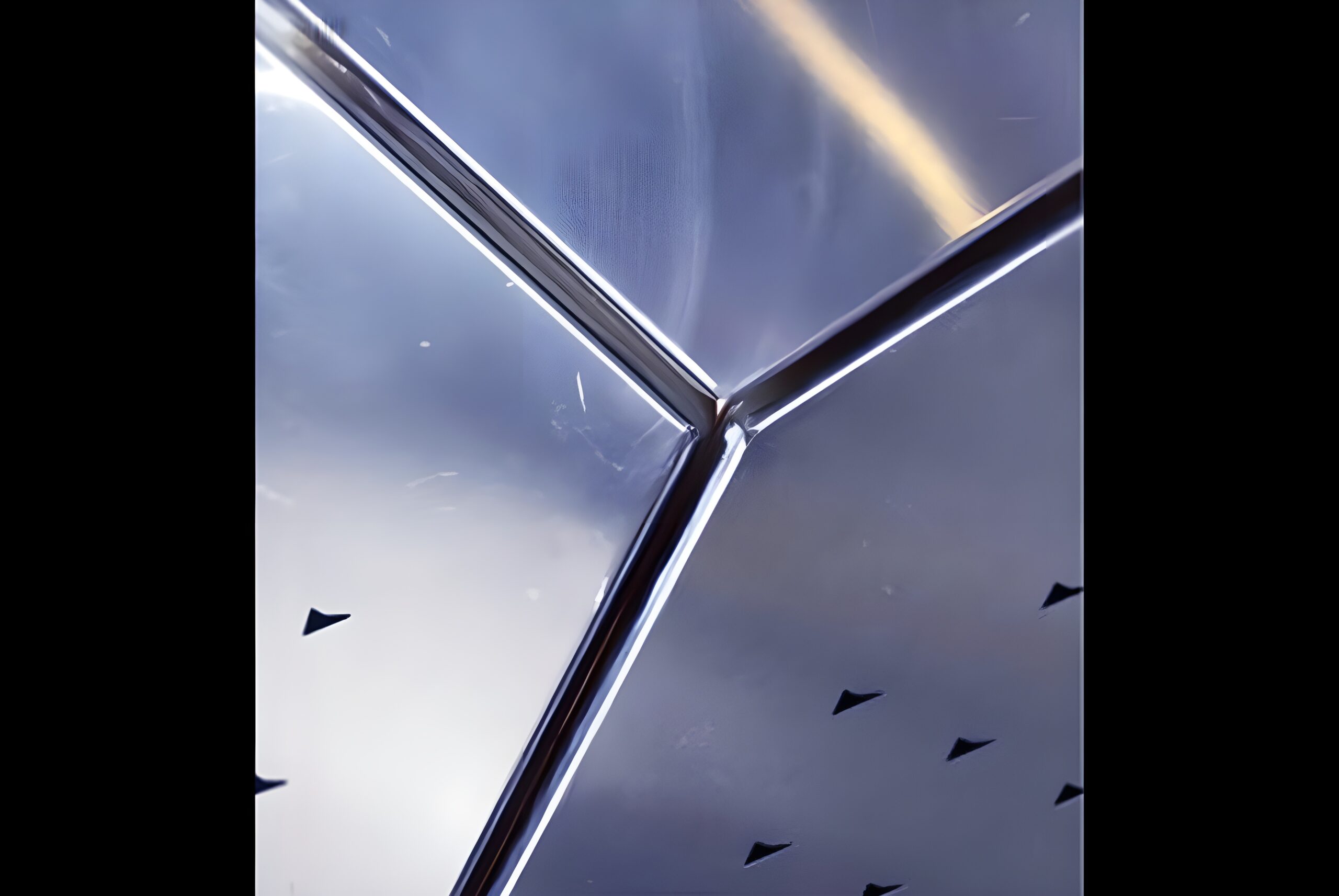

Using a screw-extrusion end effector, frames are printed with “twisted” or “ruled” edges to ensure proper connections between adjacent panels.Recycled thermoplastics, supplemented with percentages of fibers, undergo extrusion to reduce waste. Custom Grasshopper3D scripts generate both the geometry and the toolpaths for 3D printing, followed by CNC or robotic milling for assembly holes and finishing.

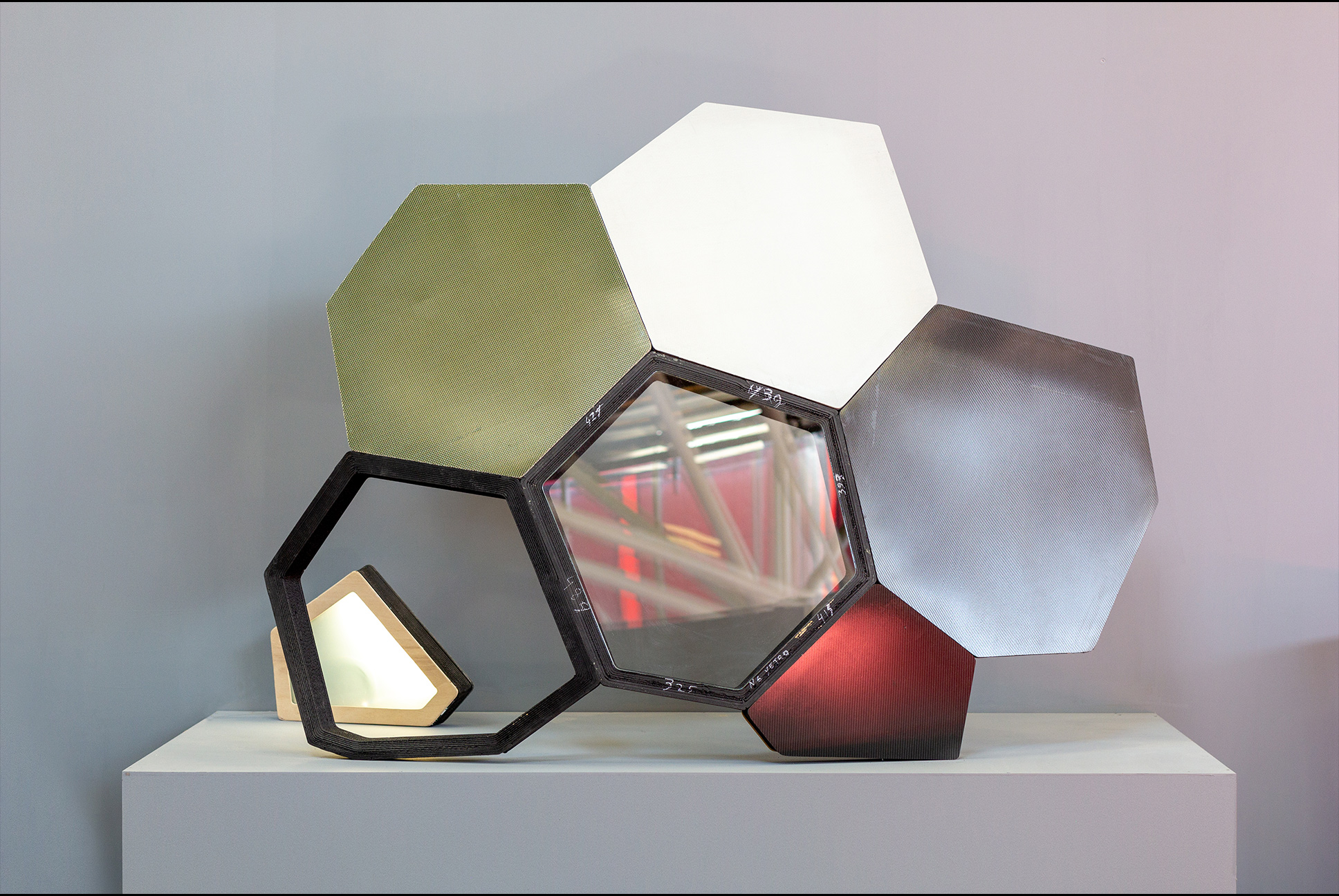

V1: Explores basic frames with different meshes (triangular, trapezoidal, hexagonal).

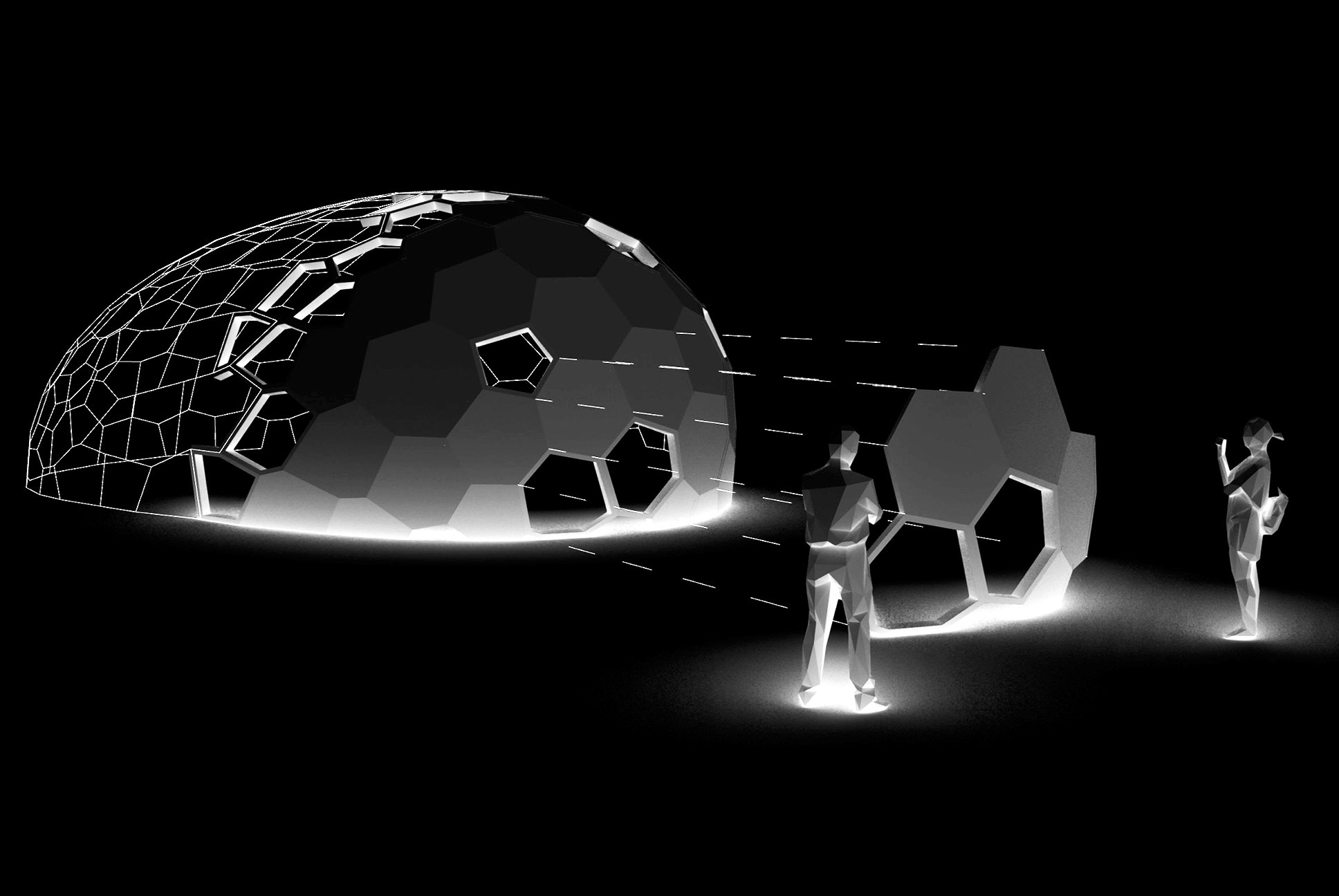

V2: Introduces directly attached panels and an aluminum-and-thermoplastic hybrid solution in the “”Urban Lounge”” installation.

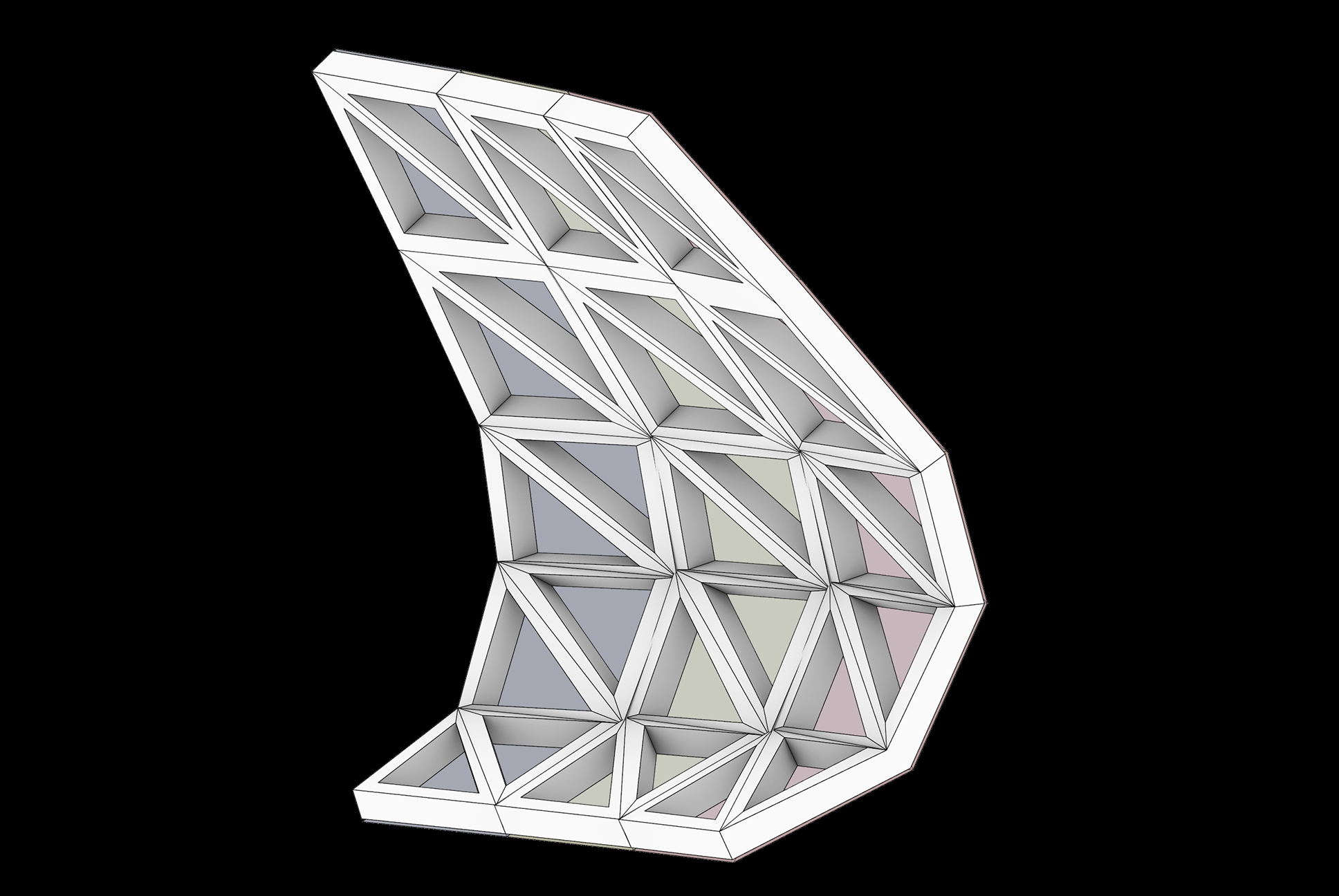

V3: Refines assembly tolerances, automates post-processing, tests high-speed printing with cooling media, and explores a surface with varying Gaussian curvature.

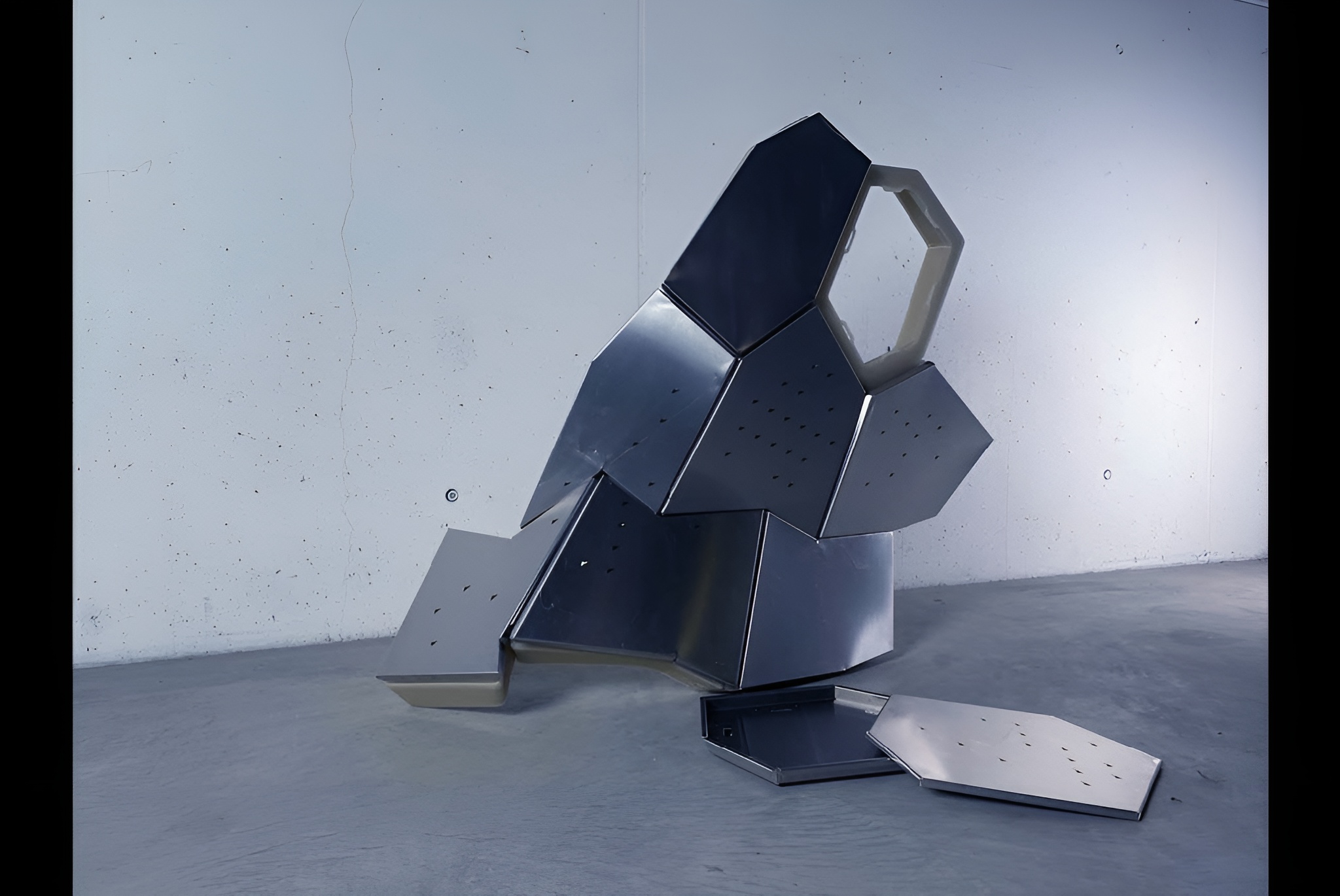

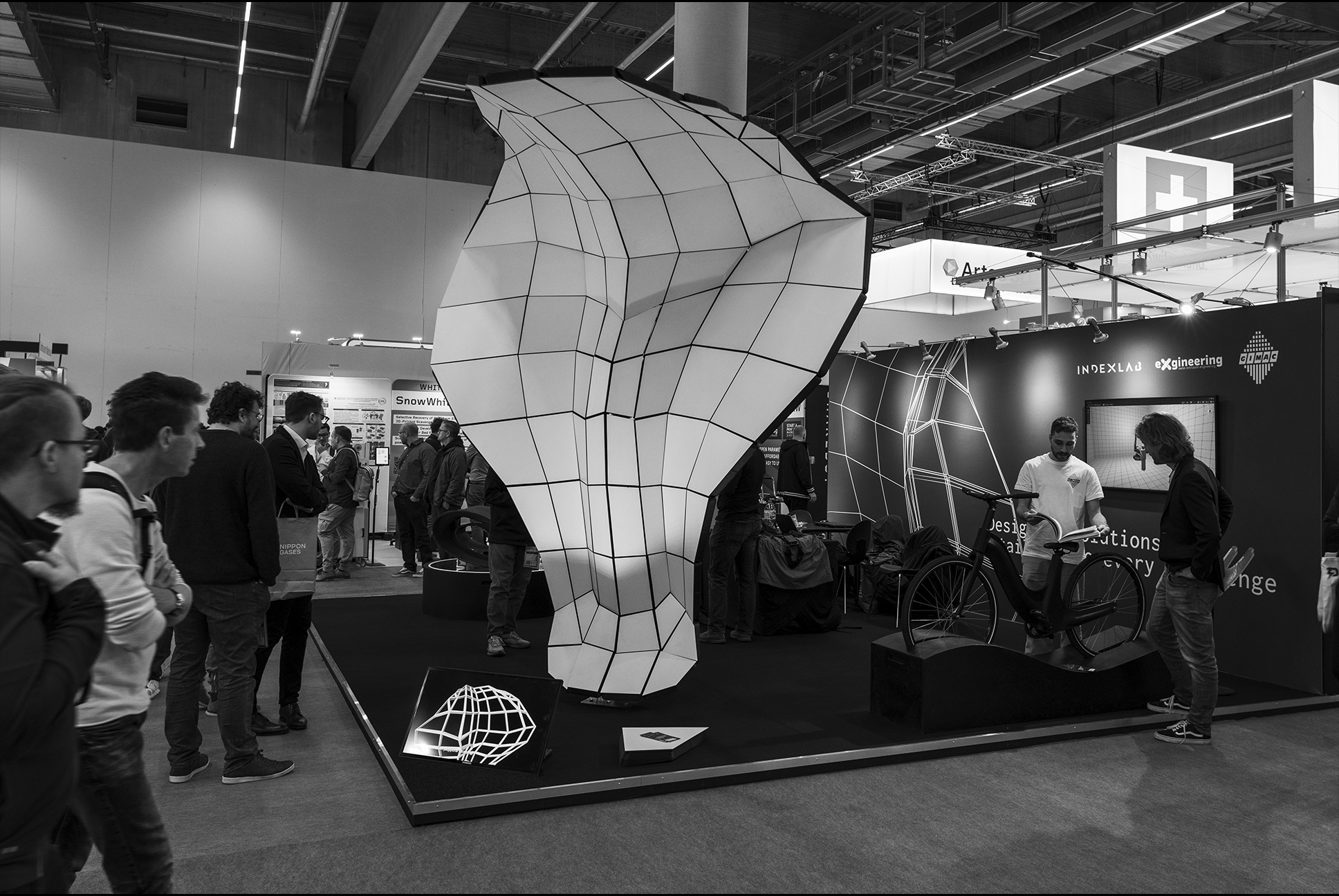

V4: “Demonstrates quadrangular panel discretization in the ‘Cobra’ installation and further integrates frames as structural connectors 3D-printed with variable layer heights, while incorporating AR to assist in assembly processes.

space

MATERIALS

Aluminum | Thermoplastics | Digital Materials

PROCESSES

DESIGNS

Screw Extrusion | CNC Drilling | CNC Routing | Robotic 3D-Printing | Augmented Reality

Triangulation | Quad Panelling | Planar N-Gons | Layering

space

ROLES

.

STAKEHOLDERS

LOCATION

.

YEAR

2020

2021

2022

2024

space