GROWING CURVES

AR-guided tube bending with growth-based toolpaths

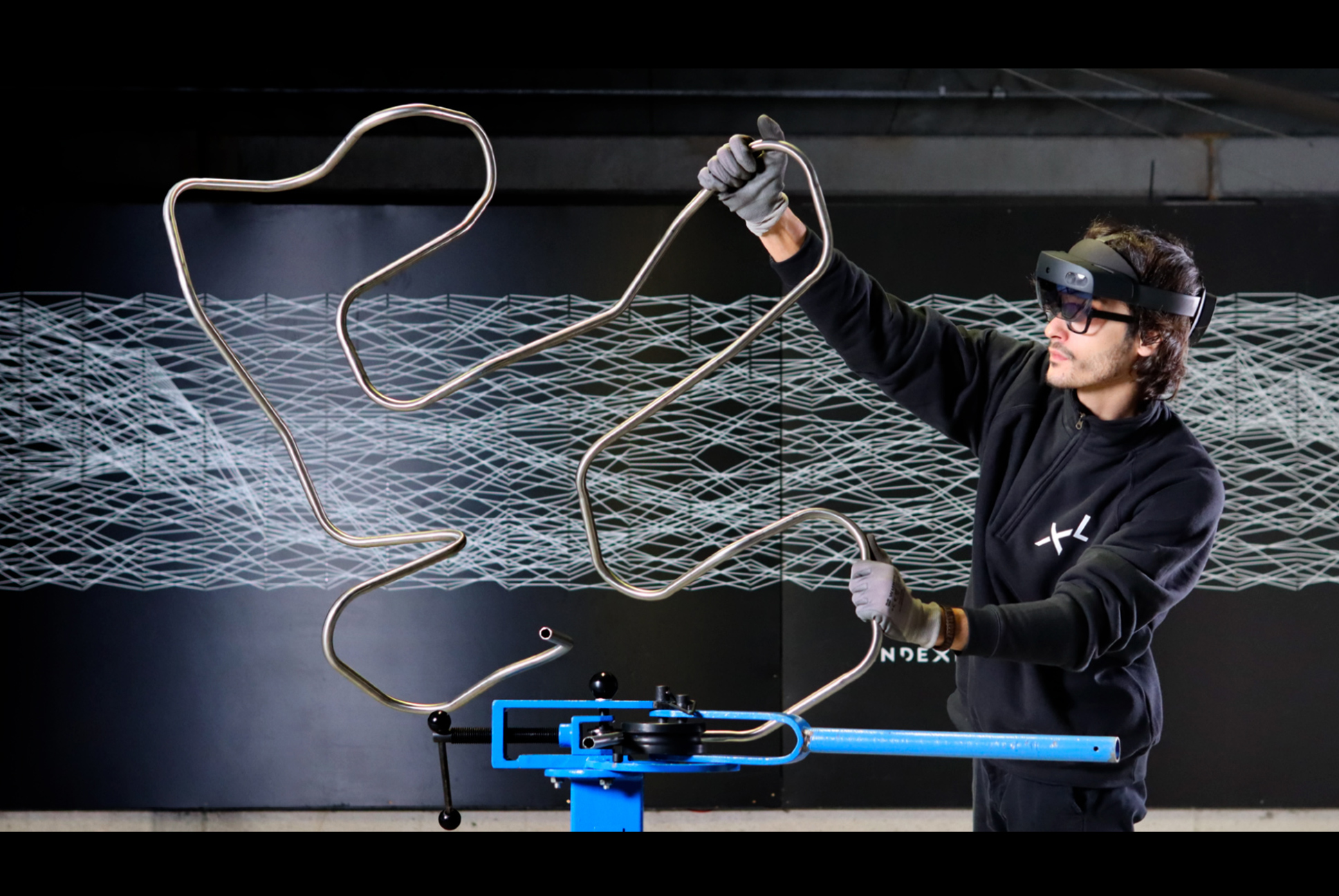

Conventional CNC tube benders are hindered by self-collision when the workpiece folds back on itself, limiting design freedom. This project introduces a compact manual bender augmented by a head-mounted augmented reality interface. Real-time holographic cues steer an operator who becomes the active actuator, while an algorithm inspired by stony-coral budding generates collision-free toolpaths that cover arbitrary surfaces. The workflow bends stainless steel tubing up to 15 mm in diameter, reproducing complex, never-intersecting polylines without machine interference. This approach merges digital pattern growth with embodied craftsmanship and opens new directions for adaptive production in architecture and product design.

CNC tube benders are accurate but their rigid frames block tight loops. Hand tools remove that obstacle but lack continuous guidance. This project therefore seeks to combine a minimal footprint bender with an AR system that synchronizes virtual geometry and physical action, preserving the maker’s tacit knowledge while benefiting from computational oversight. A dual goal is to test a growth algorithm, modelled on intra-tentacular budding in brain corals, as a generator of continuous paths that can be fabricated without self-intersection.

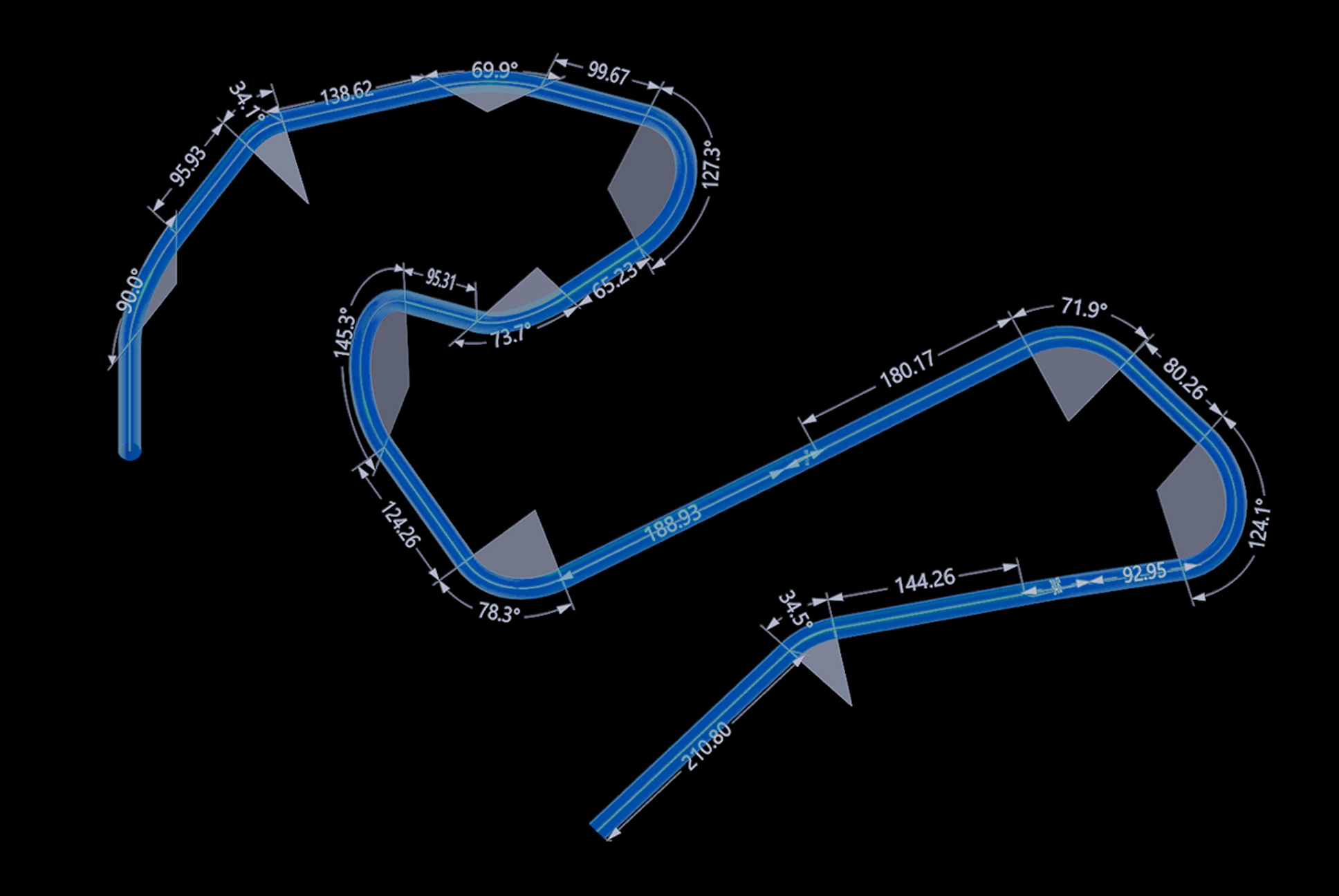

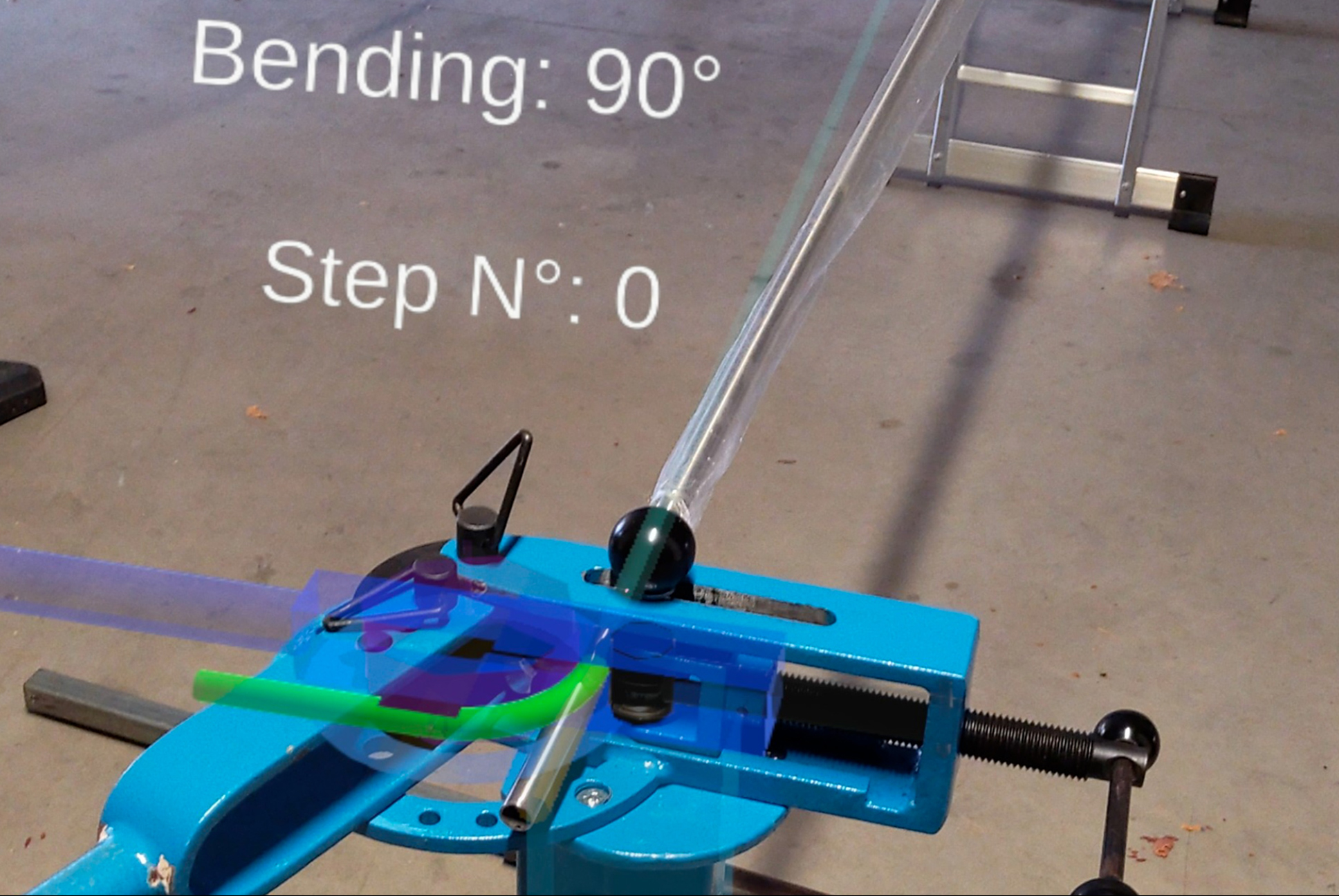

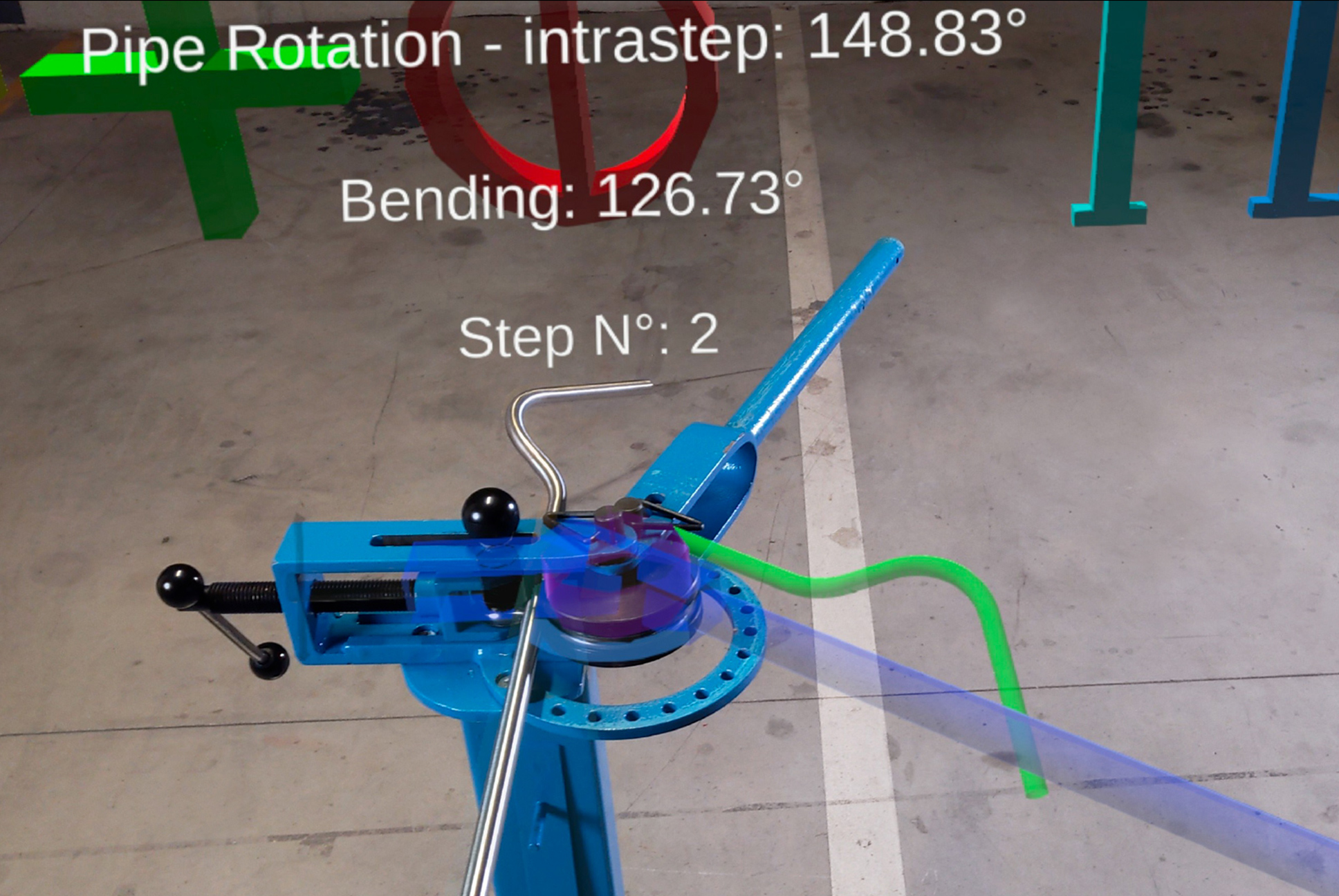

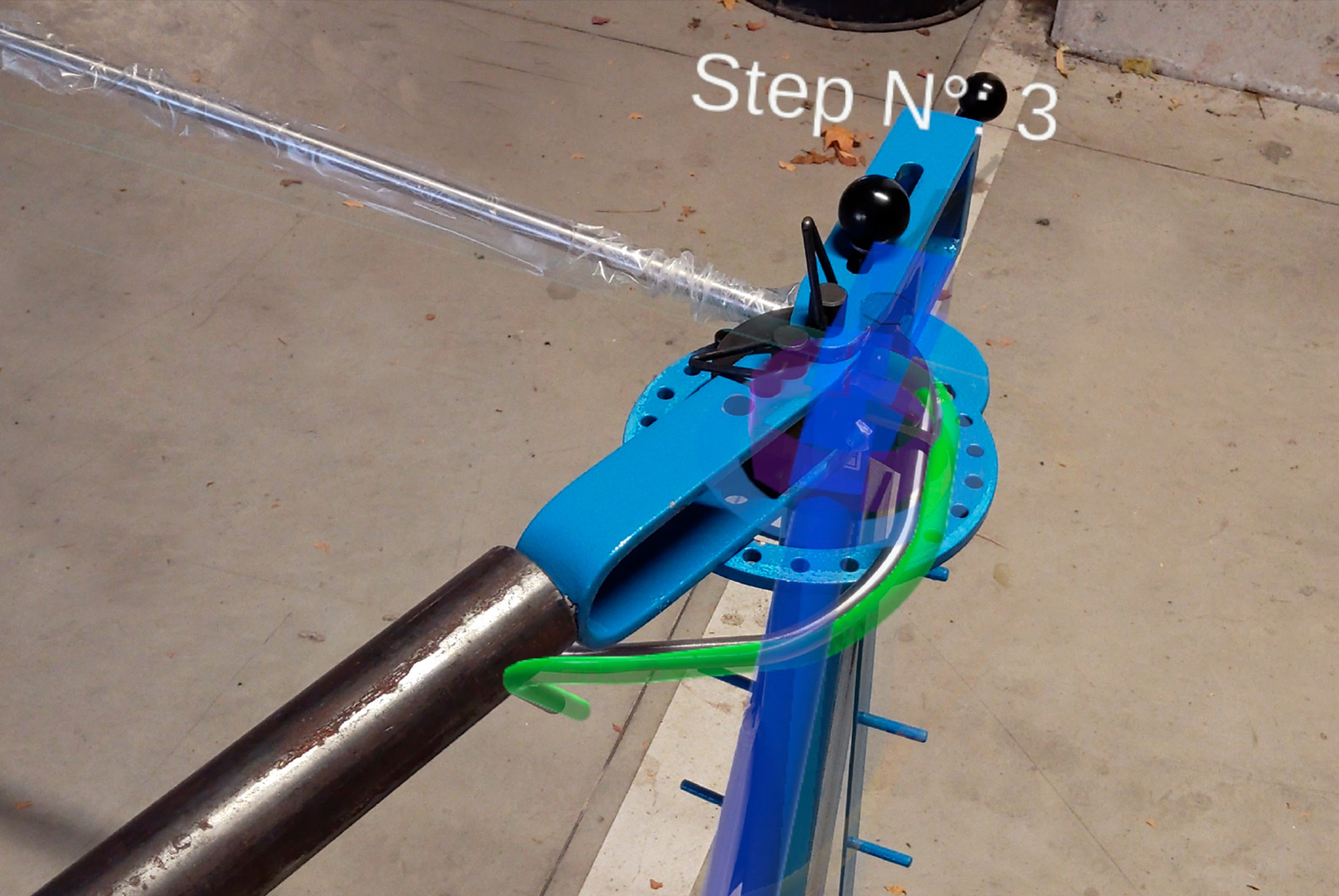

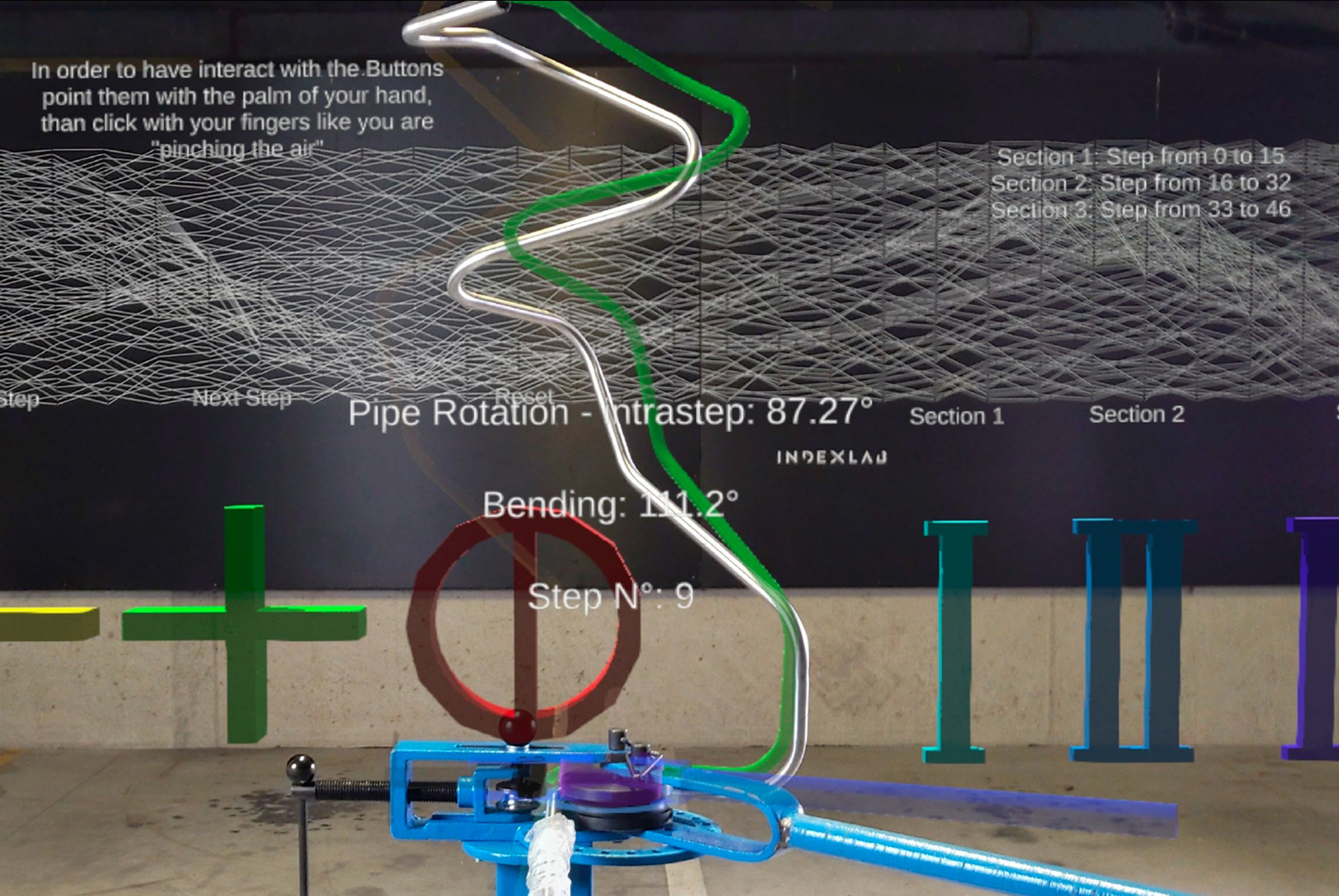

A parametric script written in grasshopper implements an iterative cell-proliferation routine. Starting from seed points on a reference mesh, the code inserts new points whenever neighbouring nodes exceed an adaptive separation distance, yielding a ranked list that defines a space-filling polyline. Straight segments are then rebuilt as constant-radius arcs using geometric offsets, aligning each arc centre with the bending plane demanded by the hand tool. The forming set-up consists of a portable rotary-draw bender. A head-mounted AR headset projects the target bend plane, live angle, and progress bar directly onto the workpiece field of view. Eye and hand tracking data modify the overlay when the user changes posture or tool orientation, keeping the hologram registered to the metal. All computation, pattern growth, registration, and instruction streaming, runs on a workstation that exchanges data with the headset.

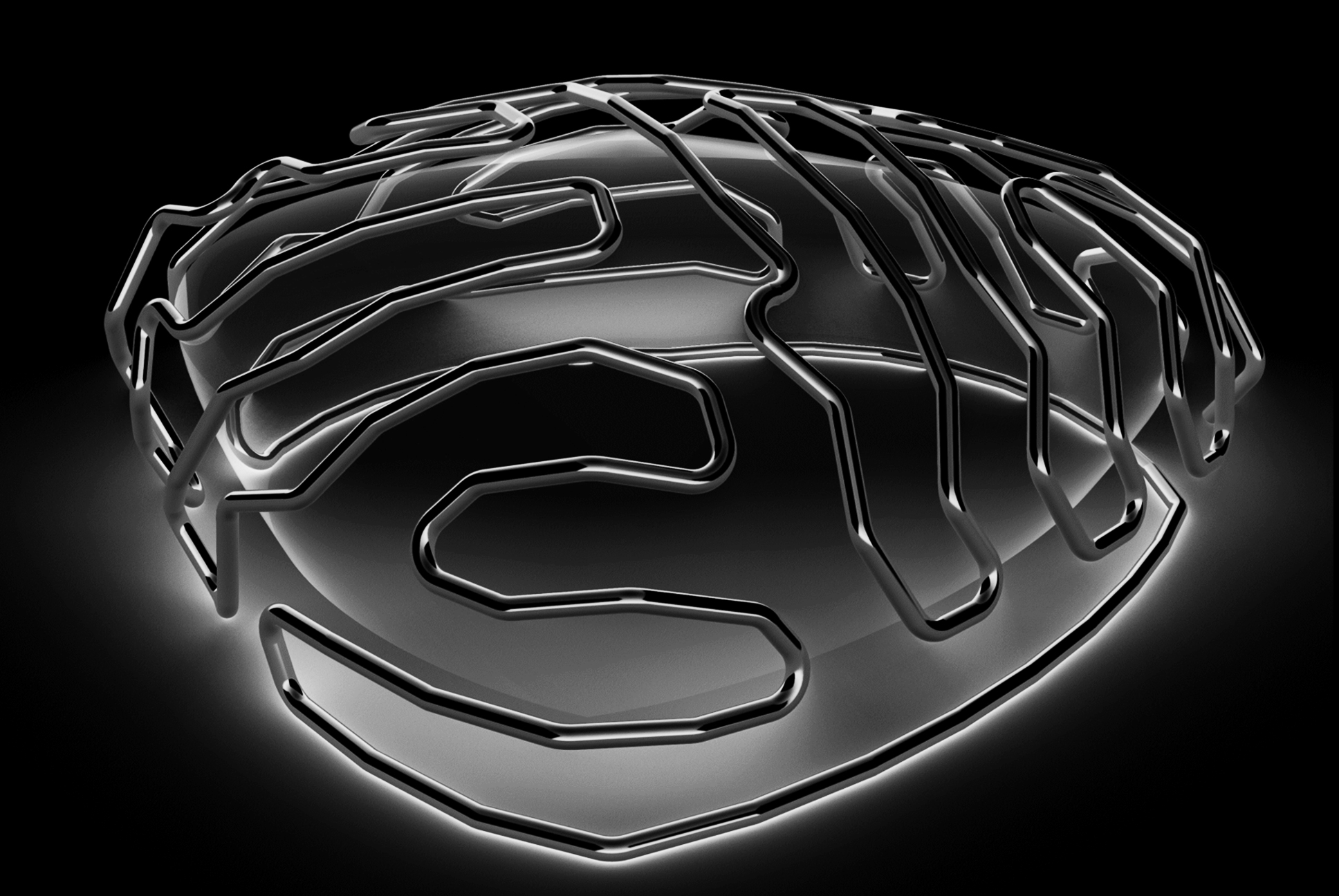

Prototype pieces exhibit the convoluted ridges characteristic of brain-coral colonies while maintaining a continuous, non-intersecting tube. Operators repeatedly form paths with diameters up to 15 mm without tube–tool collision.

Qualitative comparison with the digital model shows millimetre-scale fidelity along the path length, and users report quick comprehension of the holographic cues after a brief familiarisation period.

The system demonstrates that complex freeforms, formerly infeasible on shop-floor equipment, can be realized through human-guided bending supported by AR feedback.

space

MATERIALS

Stainless Steel | Digital Materials

PROCESSES

DESIGNS

Tube Bending | Augmented Reality

Multi-Planar Spline | Differential Growth

space

ROLES

.

STAKEHOLDERS

LOCATION

.

YEAR

2022

space