FLOWING BRANCHES

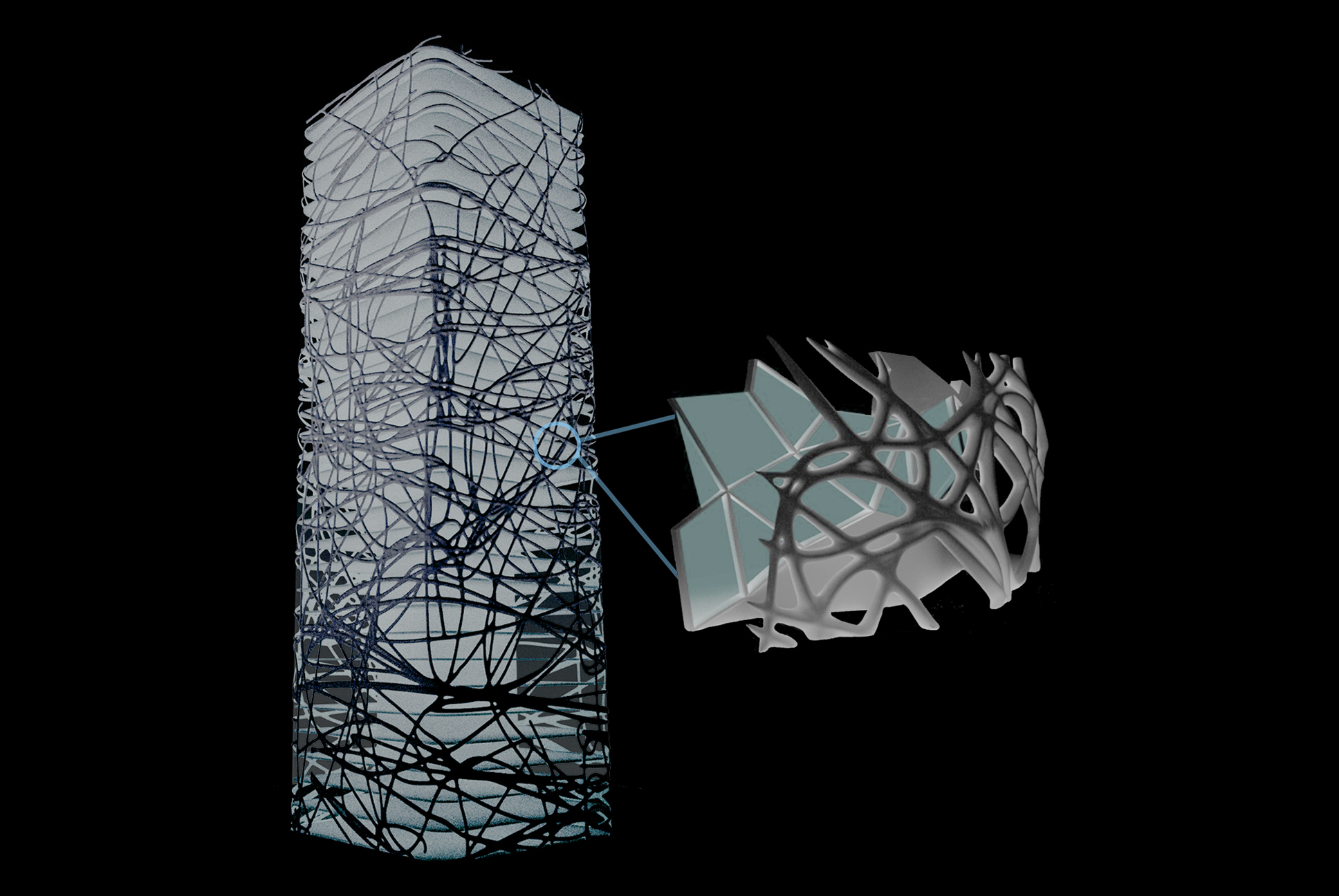

A Robotic Conformal 3D Printing System for Customizable, Double-Curved Architectural Facades

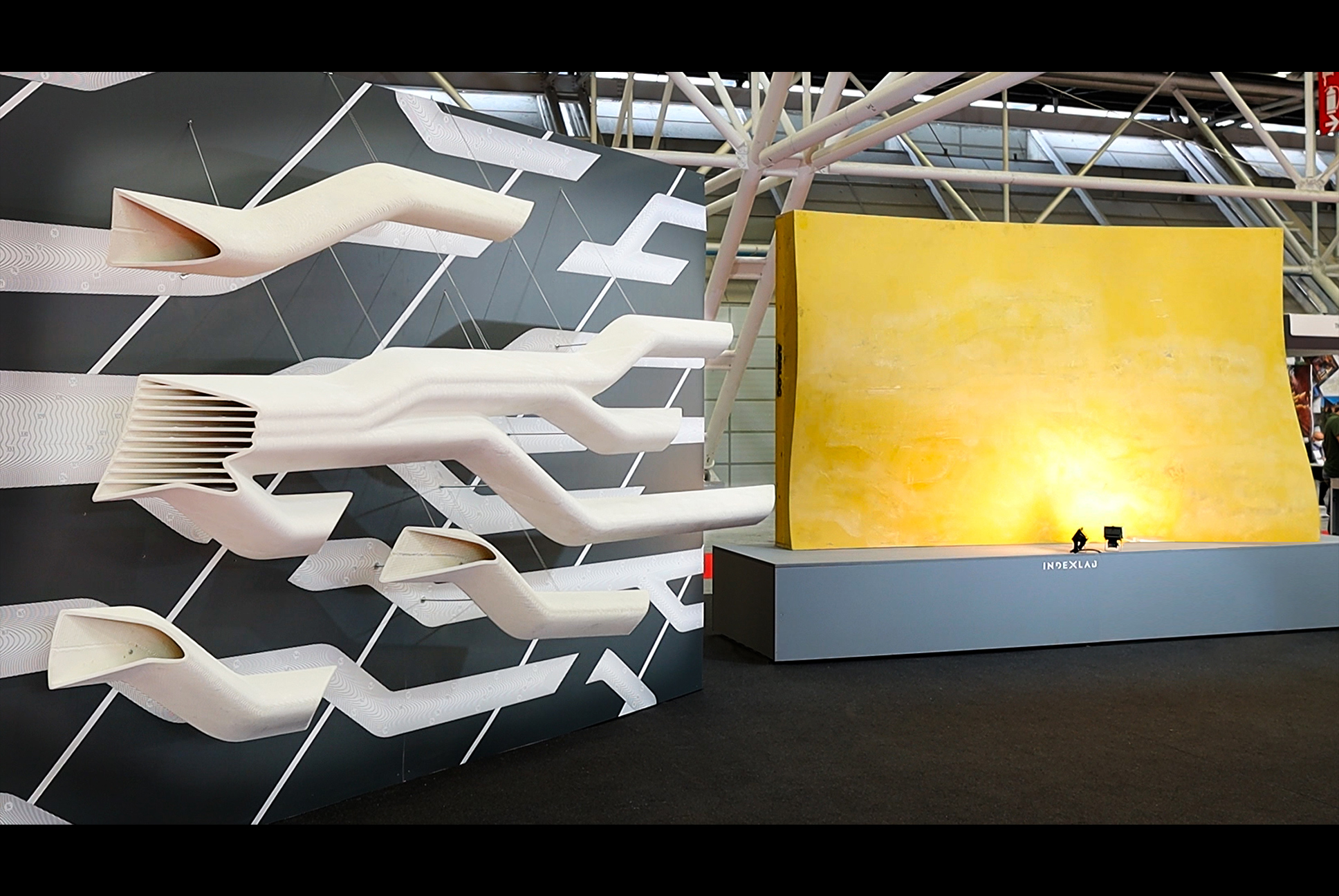

FLOWING BRANCHES is a research project exploring a novel approach to architectural facade design and fabrication. By leveraging robotic conformal 3D printing on double-curved molds, the system enables the creation of modular, expressive building skins. Each module is generated through a customized printing process that adapts to the underlying geometry, allowing for the integration of functional elements such as ventilation ducts or water drainage channels. A full-scale prototype measuring 4×2 meters was fabricated in approximately 20 hours using glass-fiber-reinforced ABS, demonstrating the feasibility of this method for producing complex, facade components.

As architecture increasingly embraces fluid geometries, conventional fabrication methods often limit design flexibility. FLOWING BRANCHES responds to this challenge with a speculative system that combines robotic 3D printing and tailored molds to produce customizable facade modules.

The project explores how digital design and advanced fabrication can converge to support new architectural languages and functionalities.

The FLOWING BRANCHES system operates through the following workflow:

Surface Discretization: the target facade is divided into submodules, each corresponding to a specific area of the overall surface.

Mold Fabrication: for each submodule, a mold with the required double curvature is produced. This mold serves as the substrate for the conformal printing process.

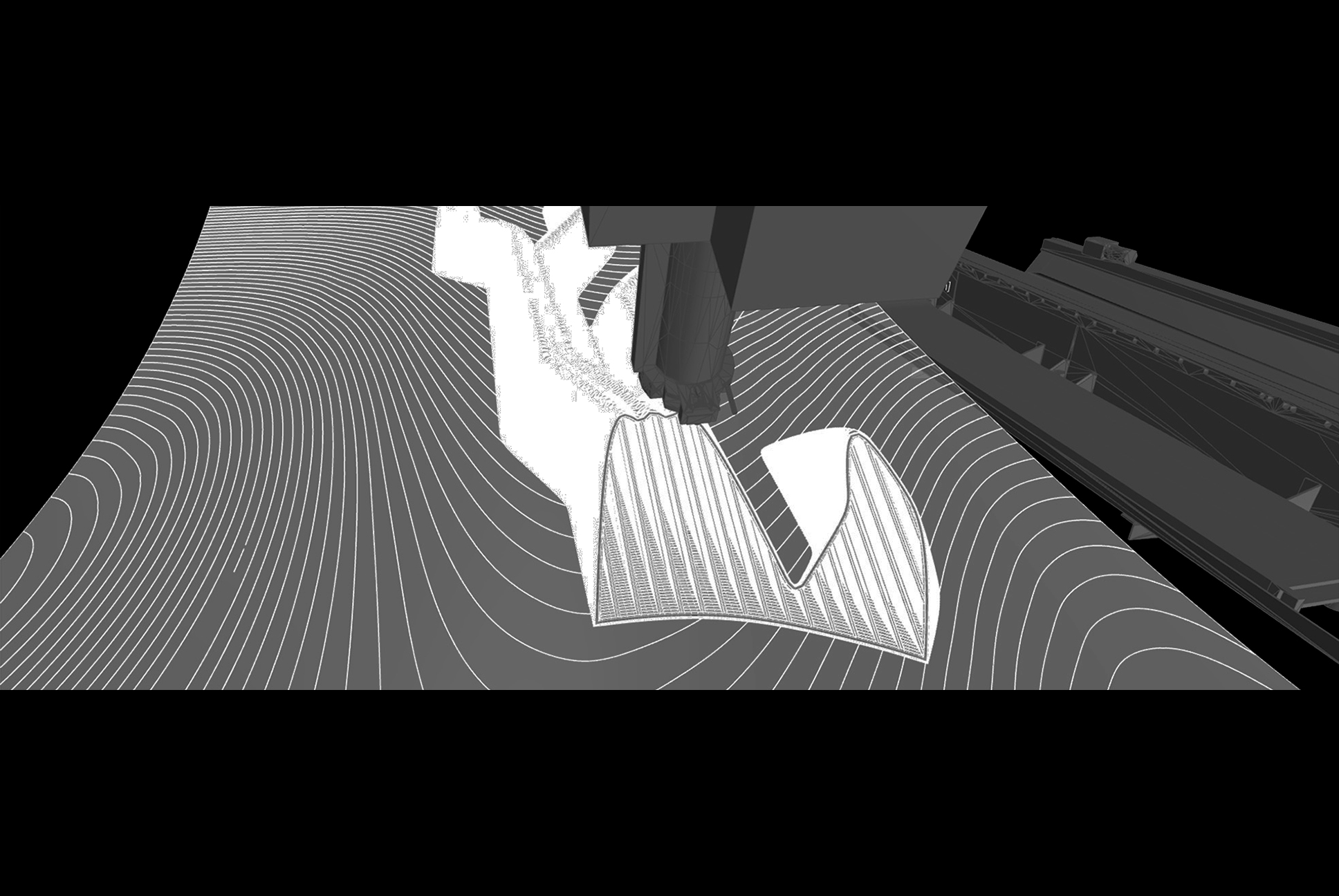

Surface Scanning and Modeling: the mold’s surface is scanned using a laser scanner to create a point cloud, which is then converted into a mesh and subsequently into NURBS geometry.

Customized Slicing: based on the NURBS model, custom slicing algorithms generate toolpaths that conform to the mold’s surface. These algorithms are tailored to optimize mechanical performance and material usage.

Robotic Printing: a robotic arm equipped with a 3D printing extruder deposits material along the generated toolpaths, building up the facade module directly onto the mold.

Module Removal and Installation: once printing is complete, the module is detached from the mold and prepared for installation on the building facade.

This methodology allows for the integration of functional features within the facade modules, such as channels for air flow or water drainage, by adjusting the printing patterns accordingly.

The prototype, developed at full scale and printed continuously over 20 hours, shows that the method is technically viable. The use of reinforced ABS ensured mechanical strength suited to facade applications. The outcome confirms the system’s potential for generating complex geometries through a repeatable, robot-assisted workflow.

space

MATERIALS

Acrylonitrile butadiene styrene (ABS) | Glass Fiber Reinforced ABS

PROCESSES

DESIGNS

Screw Extrusion | Robotic 3D-Printing

Layering | Spline Interpolation

space

ROLES

.

STAKEHOLDERS

LOCATION

.

YEAR

2020

space