ROBOPLANT

High-torque robotic solution for safer, faster tunnel segment processing in precast plants

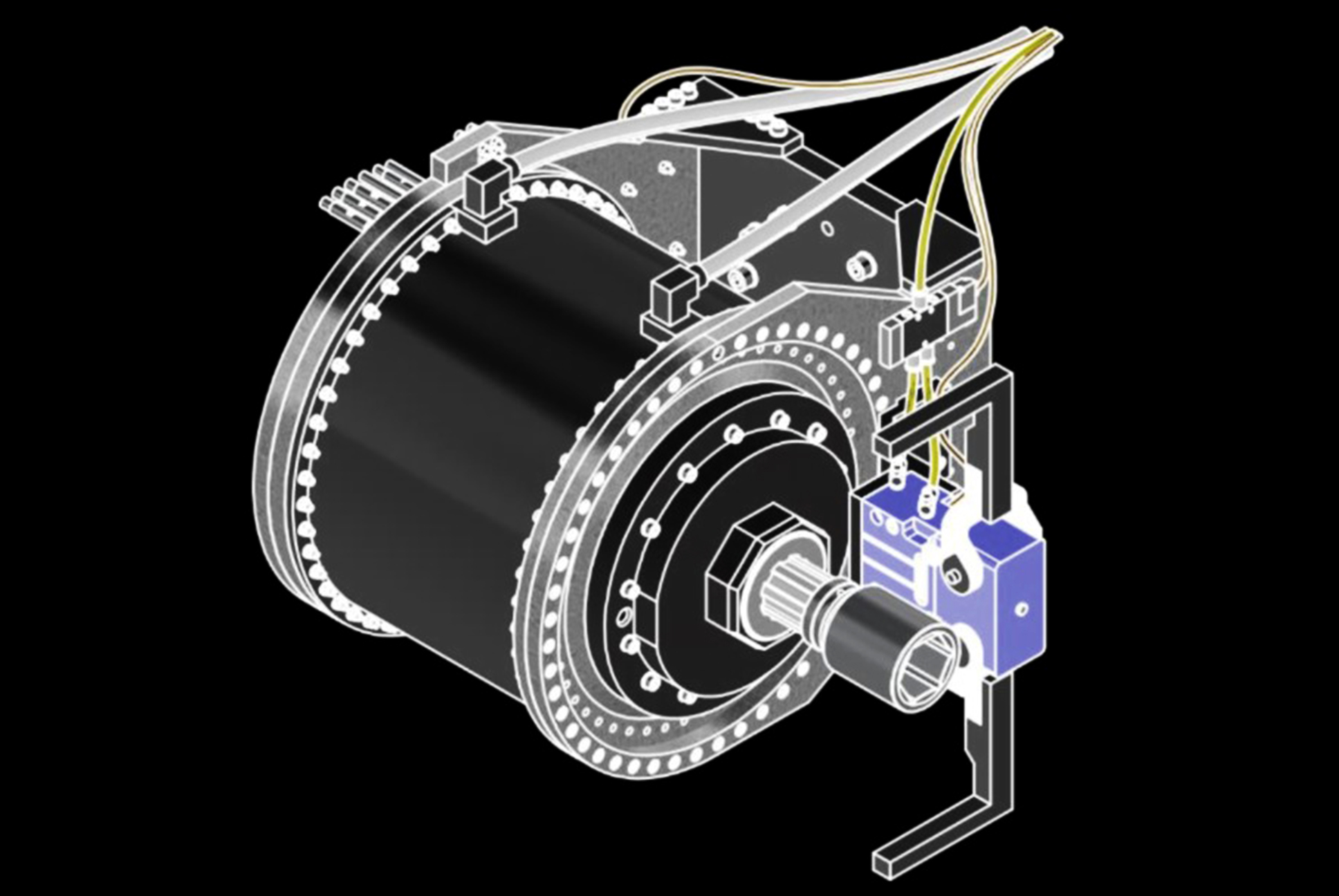

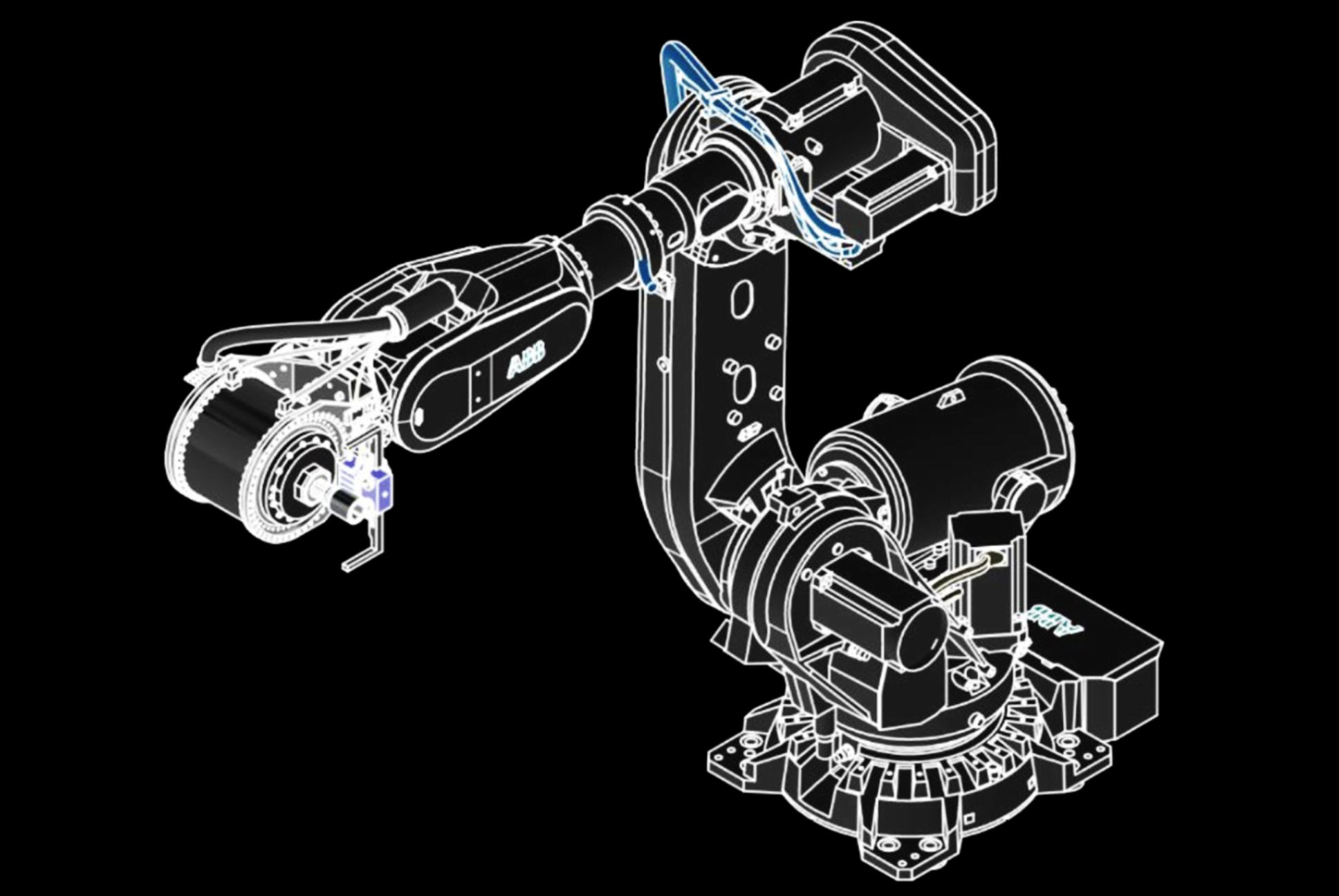

Roboplant is a robotic system for demolding and cleaning precast concrete tunnel segments. Designed to work with existing carousel molds, it features four industrial robots on linear tracks, equipped with a compact, high-torque screwdriving end-effector. This multifunctional tool unscrews bolts, grips and removes them, and seamlessly switches to cleaning with a snap-fit brush. The system increases safety, quality, and productivity in tunnel segment plants without requiring mold redesign.

Precast concrete segment production for tunnel linings involves physically demanding tasks like unbolting heavy molds and cleaning concrete residue. These manual processes are labor-intensive, hazardous, and difficult to scale for 24/7 operation. With increasing demand for productivity and worker safety, automation offers a viable alternative—but implementing robotics in this environment poses unique challenges. The key issues include delivering high torque in confined spaces, aligning tools with variable bolt positions, and cleaning complex mold surfaces efficiently. Additionally, integrating robotics without redesigning legacy molds requires innovation in both tooling and control systems. Roboplant targets these constraints by automating the most physically demanding operations, aiming to improve safety, reduce cycle times, and minimize dependence on manual labor.

Roboplant uses four robots with 1500 Nm torque tools, each compact enough to access standard molds. Vision systems guide precise tool alignment, and torque control prevents overloading. A snap-fit brush converts the tool for cleaning. Robots operate in parallel to open, clean, and prepare molds. The system integrates into existing production lines with no need for tool changers or mold modifications.

Roboplant reduced cycle times by up to 60%, doubled output, and maintained high consistency in segment quality. Plants saw labor reductions of up to 50%, improved safety, and better surface finishes. Its ability to retrofit legacy molds made adoption cost-effective, and its deployment across multiple factories confirmed scalability and reliability.

space

MATERIALS

Concrete

PROCESSES

Robotic Bolting and Screwing | Robotic Surface Finishing | Vision Systems | MicroProcessor | Torque Motor

space

ROLES

.

STAKEHOLDERS

LOCATION

.

YEAR

2022

space