SNAKE

AR-guided fabrication system for assembling freeform strip-based geometries without molds

SNAKE introduces a fully computational methodology for fabricating and assembling freeform geometries, particularly double-curvature surfaces, without the need for molds or formworks. This is achieved using the MeshGraph-Based Strips Network, which simplifies complex geometries into manufacturable strip layouts. Augmented-Reality (AR)-guided assembly makes it easier to bend flat-cut strips to their original curvature and position them on the geometry, aligning edges and holes for proper connections. Prototypes validate the system’s adaptability and its effectiveness in simplifying fabrication and assembly, demonstrating its potential for construction applications such as facades and shading installations.

The MeshGraph-Based Strips Network represents a transformative approach to fabricating freeform geometries in architecture. By utilizing graph theory algorithms, this system translates complex surfaces into manufacturable strip networks that align with the surface’s natural curvature. Snake builds upon this computational foundation, presenting the system as an adaptable solution for various building construction systems, including partitions, walls, louvers, shading devices, and ceilings.

Traditional fabrication methods for making freeform complex geometries, which rely on molds, result in significant material waste, as molds are specific to each shape and are discarded after use.

However, this new method introduces challenges in the assembly process, as each strip is unique, must be bent to specific angles, and placed in a precise orientation and order. Snake addresses these challenges using AR to guide the bending and placement of strips, speeding up assembly and making the overall process feasible for complex geometries.

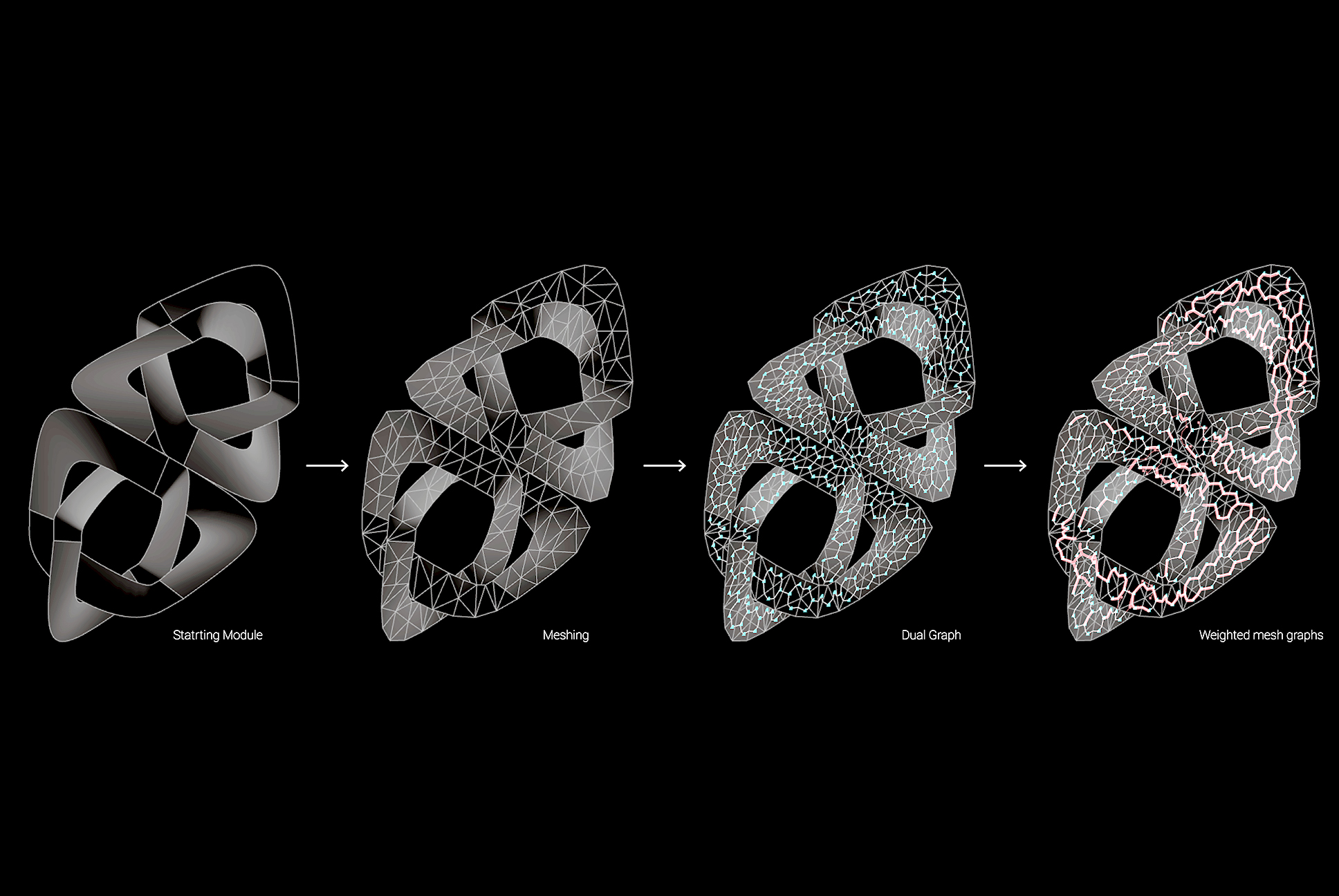

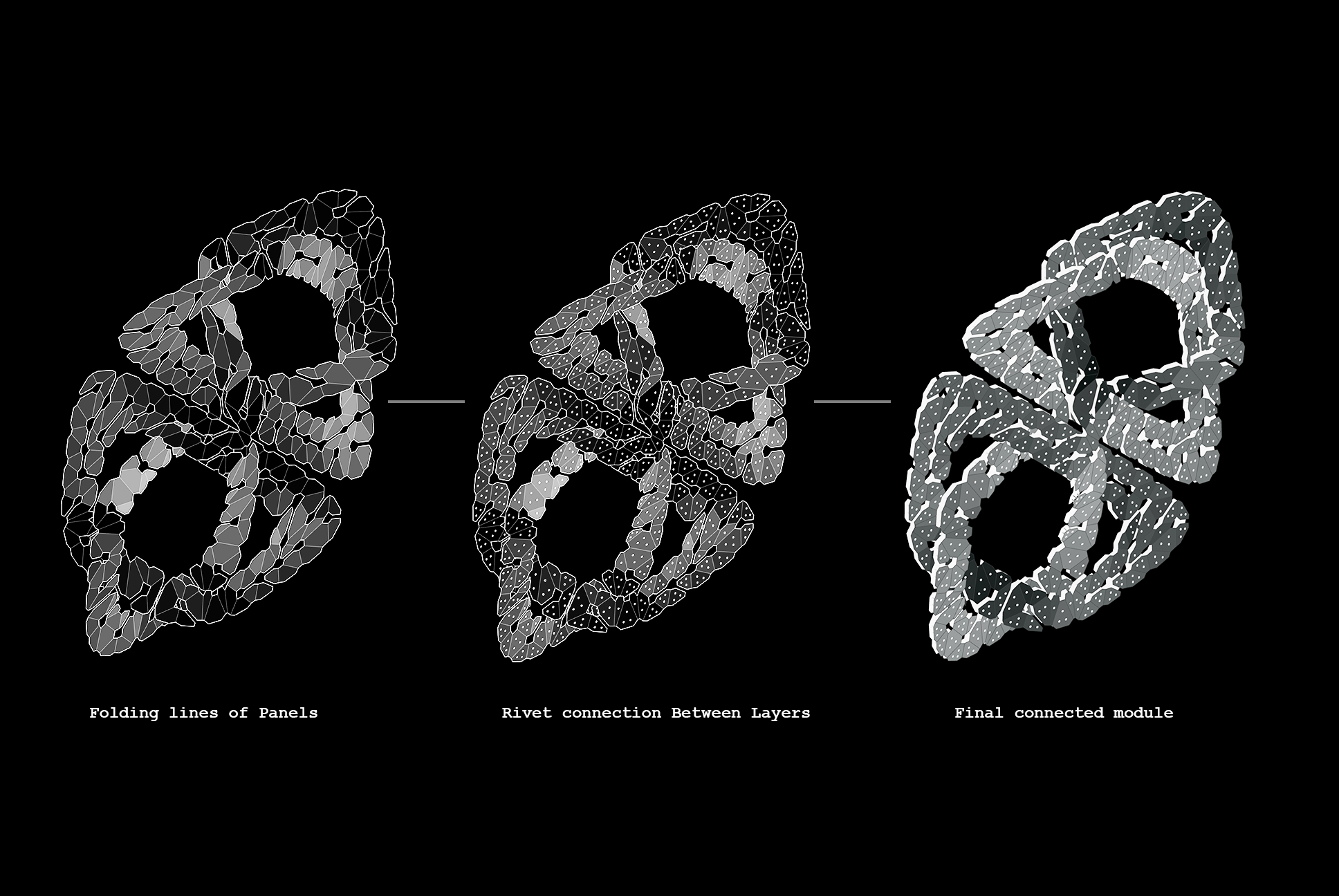

SNAKE uses a combined approach of mesh segmentation, surface discretization into strips, and AR-guided assembly, refined through iterative prototyping to address curvature transitions, strip alignment, and connection accuracy.The process starts by converting input geometry into a triangular mesh for accurate surface approximation. Grasshopper’s Ivy plugin generates a dual graph where nodes represent mesh faces and edges define their connections. Edge weights—based on curvature, edge length, proximity, and face angles—guide segmentation by promoting smooth transitions and alignment with the surface flow.Segmentation divides the mesh into continuous strips that follow curvature while minimizing branching and overlaps. Grasshopper’s “Orange Peel” algorithm optimizes edge removal, and Galapagos refines parameters to produce organized, unrollable strip layouts. This enables a clean transition from 3D geometry to flat, manufacturable components while preserving curvature and alignment for precise reassembly.

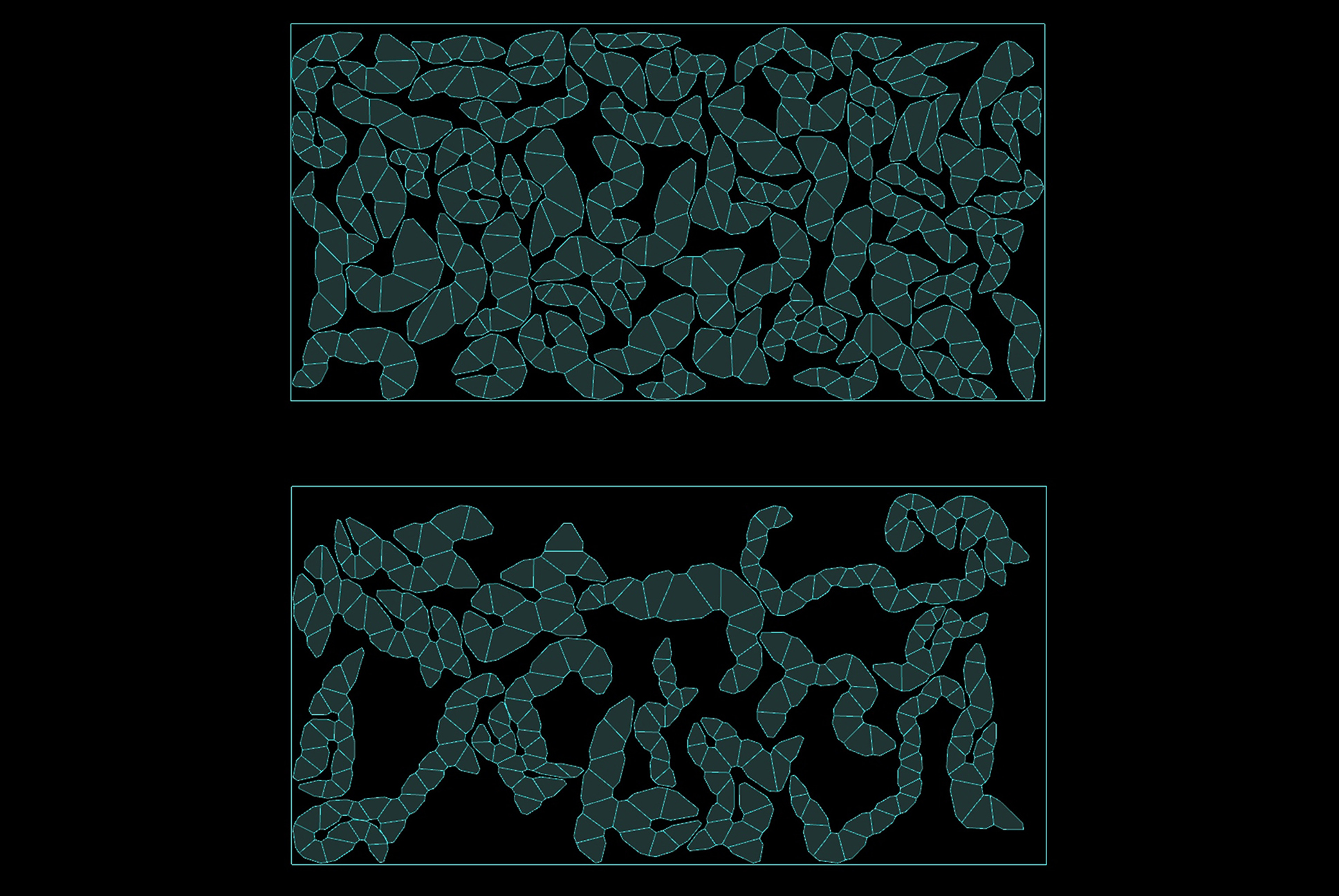

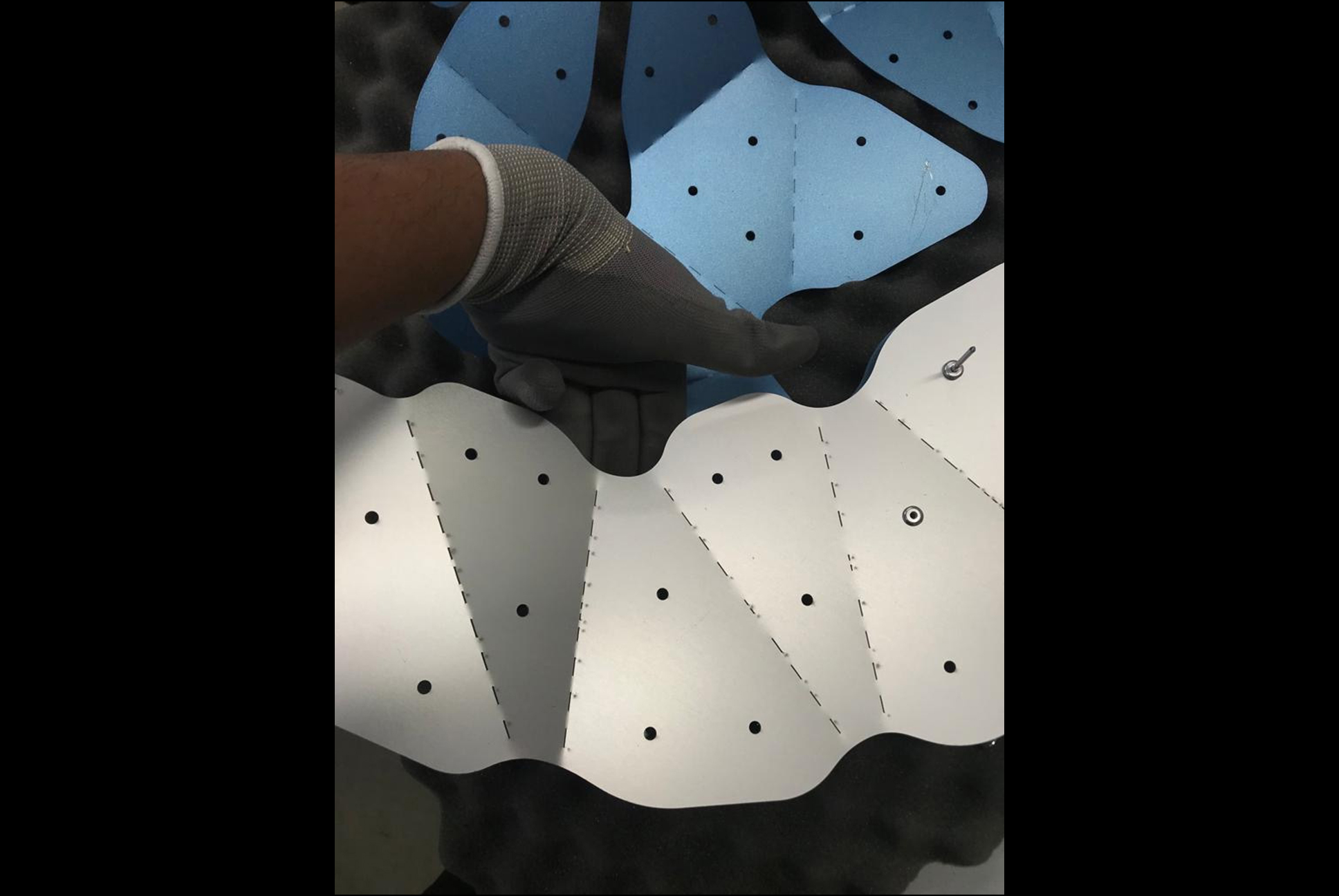

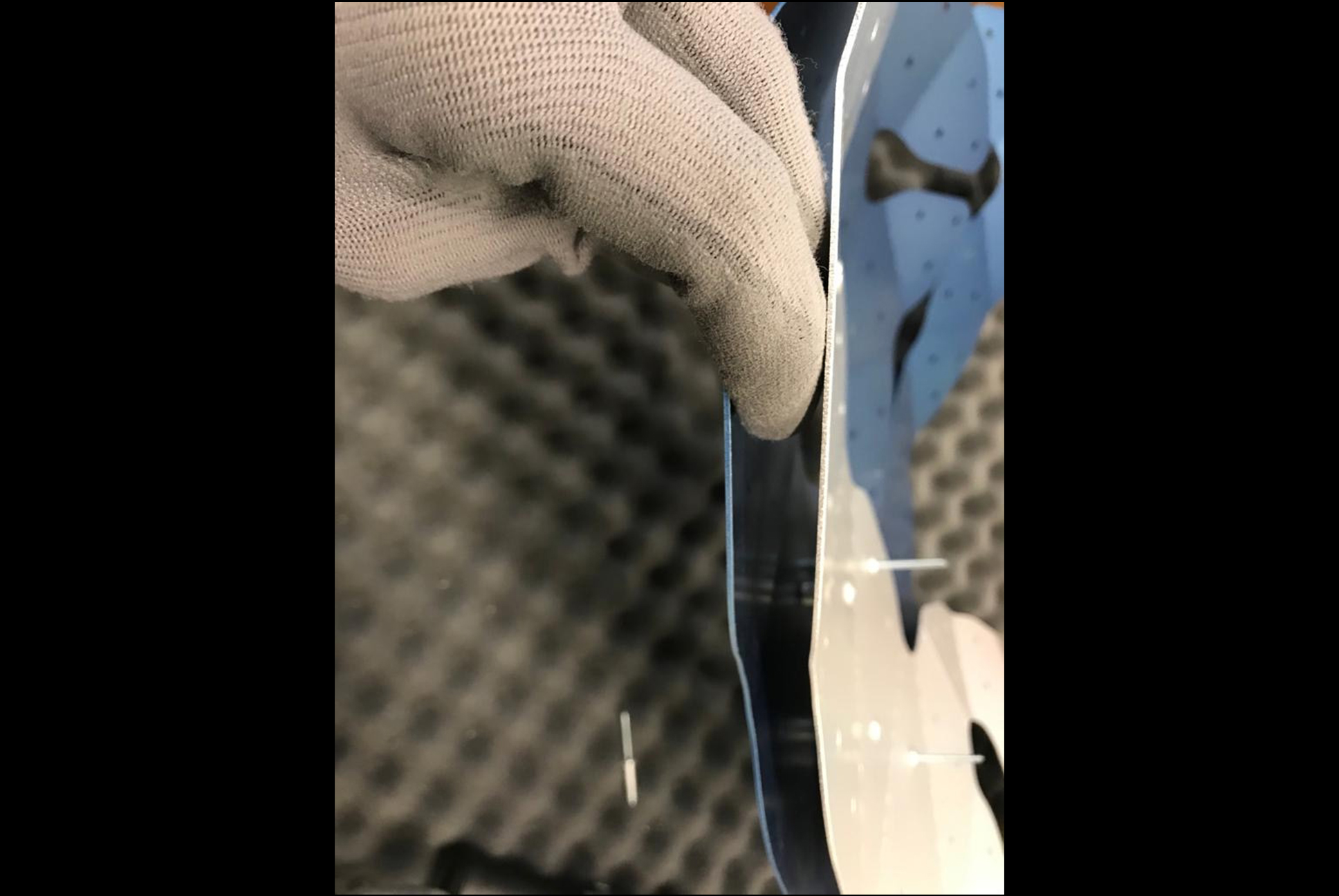

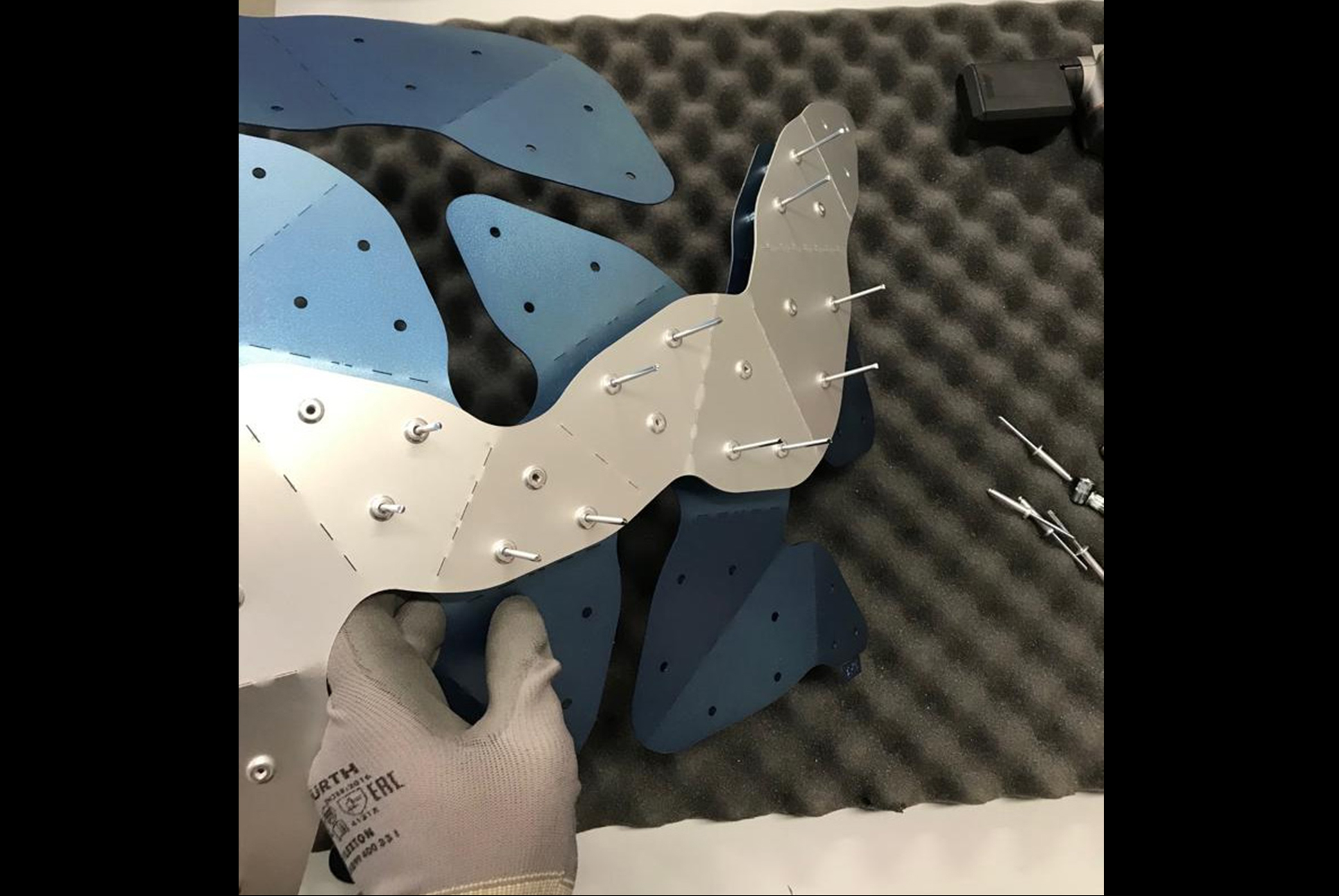

Once strip layouts are finalized, they are unrolled into flat panels and nested onto standard-sized sheets using OpenNest to optimize material use and minimize waste. Each panel includes fabrication-specific details—etched fold lines for bending, pre-cut rivet holes, and labels for sequencing and identification. Aluminum is selected for its light weight, malleability, durability, recyclability, and compatibility with CNC, waterjet, and laser cutting.

Assembly is guided by Microsoft HoloLens2 with Fologram, which assists in bending the strips to achieve curvature and overlays digital guides for accurate alignment of rivet holes and edges. Rivets secure adjacent strips, while spacers ensure consistent panel spacing.

This layered assembly transforms the structure from a flexible membrane into a stiffer form resembling a shell, capable of resisting both in-plane forces and out-of-plane bending for improved load response and shape retention.

Iterative prototyping validated the system’s adaptability across geometries and led to refinements in spacer spacing (for hand access during riveting), labeling for assembly sequencing, and enhanced AR guidance for bending and alignment.

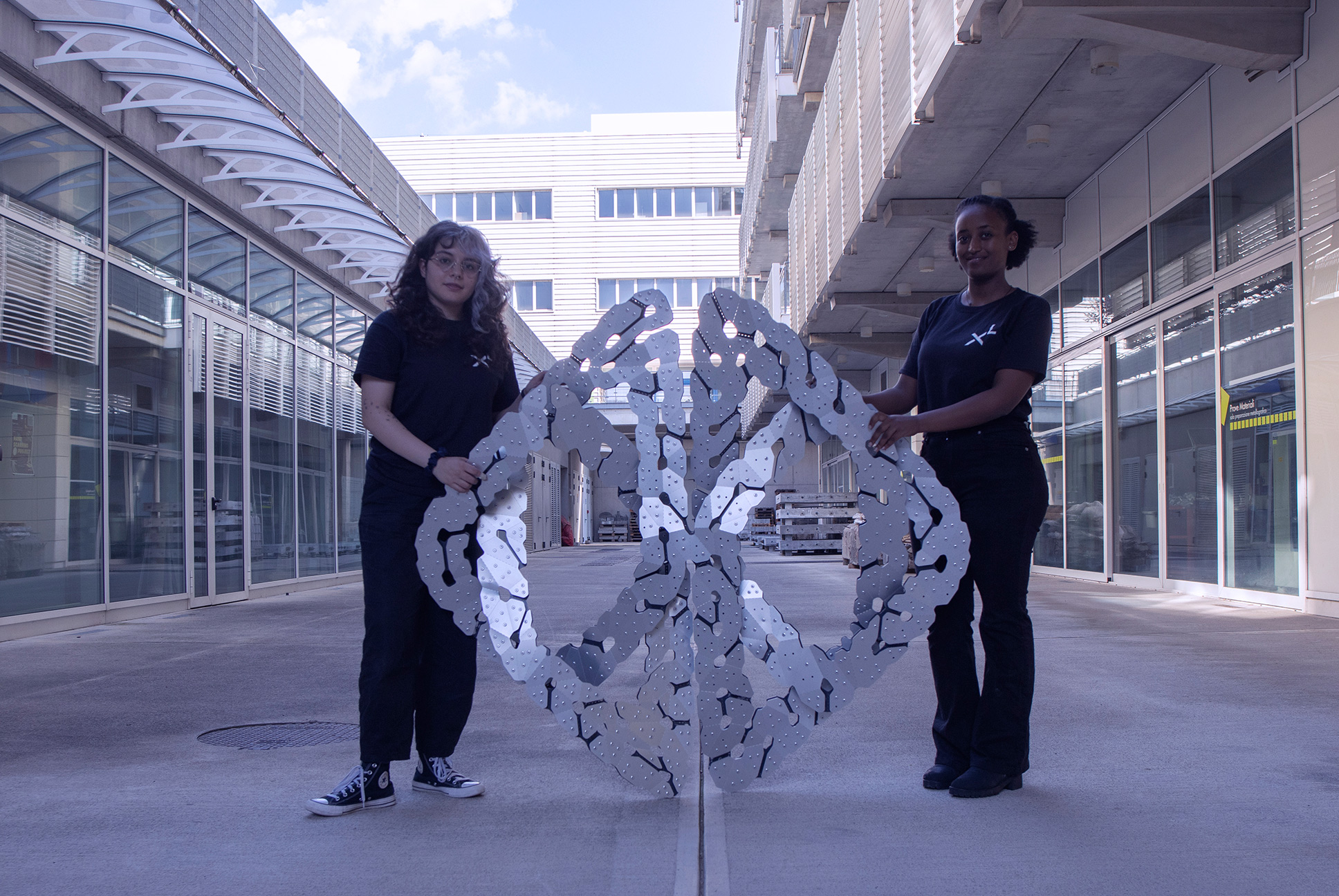

Prototypes and installations demonstrate the effectiveness of the MeshGraph-Based Strips Network in fabricating and assembling freeform geometries. Assembly, initially considered challenging or even impossible, became feasible and fast with the support of AR-assisted workflows.

The first project features a large-scale freeform shading surface wrapping around a building, composed of hundreds of aluminum strips, each fabricated from a small number of aluminum sheets.

The second project demonstrates a modular approach with shading elements, where each module measures 1.2 × 1.2 meters and includes 27 strip panels—11 on the front and 16 on the back—fabricated from a very small number of aluminum sheets. Both projects were optimized to minimize material usage, reducing the total number of aluminum sheets required for fabrication.

space

MATERIALS

Aluminum | Digital Materials

PROCESSES

Fiber Laser Cutting | Sheet Plate Bending | Riveting | Augmented Reality

DESIGNS

MeshGraph-Based Strips Network | Lofting | Evolutionary Algorithms

space

ROLES

.

STAKEHOLDERS

LOCATION

.

YEAR

2022

2024

space