PLANTBLOCK

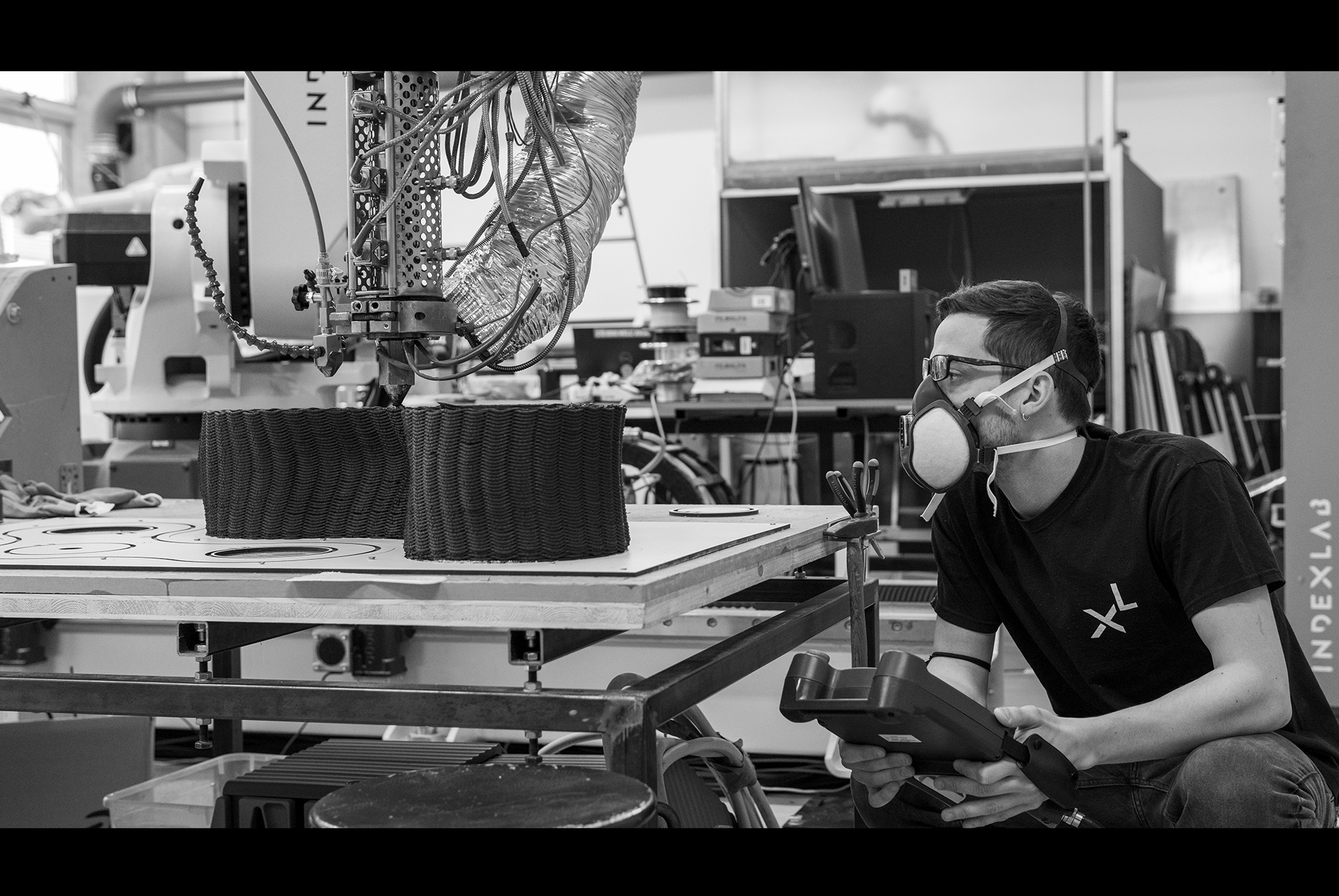

Robotic screw-extrusion of recycled ABS modules for reconfigurable stacking assemblies

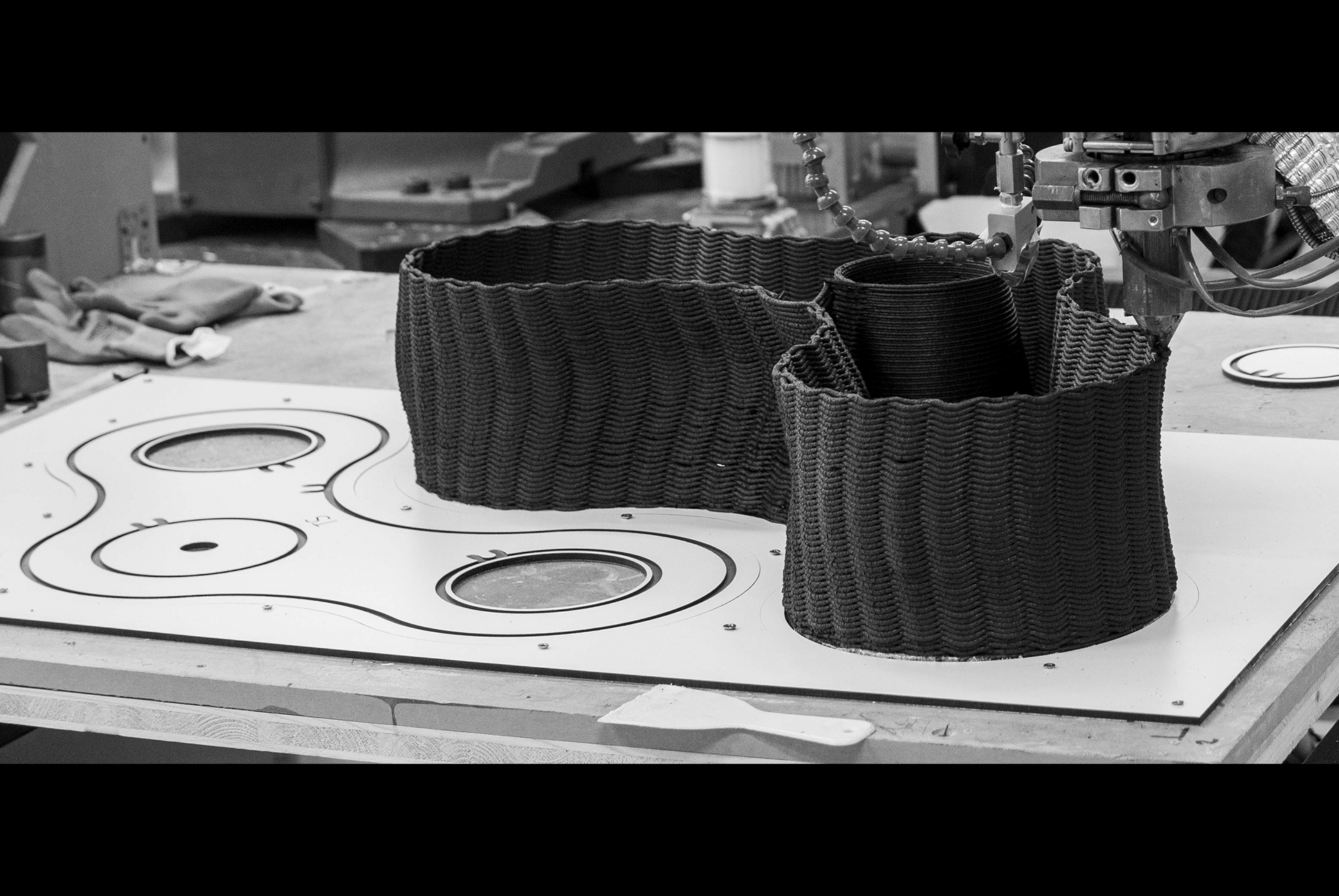

PLANTBLOCK is a research project that investigates discrete architecture through robotic fabrication, combining recycled materials with parametric methods. The module’s form derives from three offset yet tangent circles arranged in a triangular pattern, joined by tangent arcs to create a unified surface. Two of the circle centers feature small extruded cylinders—comparable to LEGO studs—that enable rotational freedom and stacked aggregations. This configuration supports dynamic assembly while addressing sustainability goals by reusing Acrylonitrile Butadiene Styrene (ABS) waste through robotic additive manufacturing (RAM).

The objective is to develop a lightweight, reconfigurable, and efficiently fabricated module adaptable to both spatial and functional contexts. A key challenge involves identifying a geometry that allows more complex aggregations beyond typical LEGO-like stacking, while meeting the constraints of recycled ABS and robotic fabrication, particularly in relation to material behavior and integration with high-pressure laminate (HPL) panels.

Fabrication begins with the milling of HPL panels using a dovetail-shaped end-effector, shaping the upper and lower surfaces of the module.

Using RAM, a first layer is deposited to adhere to the milled curves, ensuring effective bonding.

The 3D printing continues along a doubly curved surface that shifts gradually from concave to convex.

Each printed layer follows a woven pattern—alternating ins and outs—to handle material irregularities and the limitations of RAM, while also contributing to the piece’s overall materiality.

Parametric modeling via Grasshopper and the WASP plug-in controls how modules rotate and connect around the Z-axis, using the studs as mechanical pivots.

PLANTBLOCK offers a flexible alternative to traditional modular systems by merging recycled ABS plastic with robotic additive manufacturing.

Its printed shell expresses the form while acting as a structural skin, replacing molds with a lightweight, load-sharing surface that embodies both materiality and process.

space

MATERIALS

Acrylonitrile Butadiene Styrene (ABS) | High-Pressure Laminate(HPL)

PROCESSES

DESIGNS

Screw Extrusion | CNC Routing | Robotic 3D-Printing

Slicing | Discrete Part-Based Modularity

space

ROLES

.

STAKEHOLDERS

LOCATION

.

YEAR

2022

space