MARS HABITAT

Autonomous 3D-printed habitats on Mars using local materials and robotic swarms

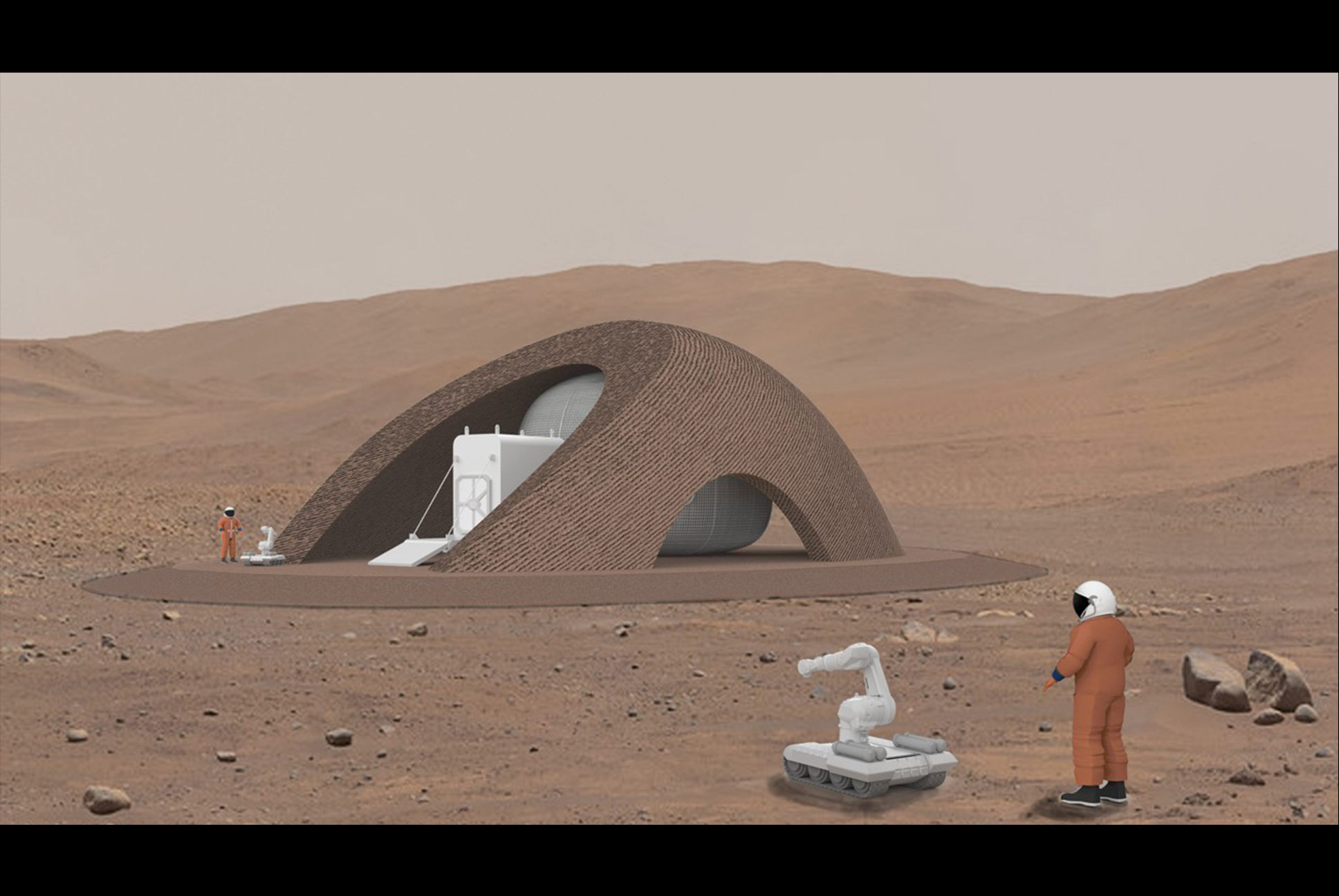

This project investigates a methodology for constructing Martian habitats through robotic 3D printing with in-situ resources. It explores how autonomous systems could one day perform site evaluation, material processing, and additive manufacturing. A conceptual framework based on swarm robotics is proposed, though not yet prototyped. Initial experimentation focuses on a mobile rover with an integrated extrusion system. Using a Marscrete-like mixture, a small-scale dome was fabricated to simulate additive construction under Martian constraints. Results point to both the potential and the current limitations of deploying robotic systems for off-Earth infrastructure.

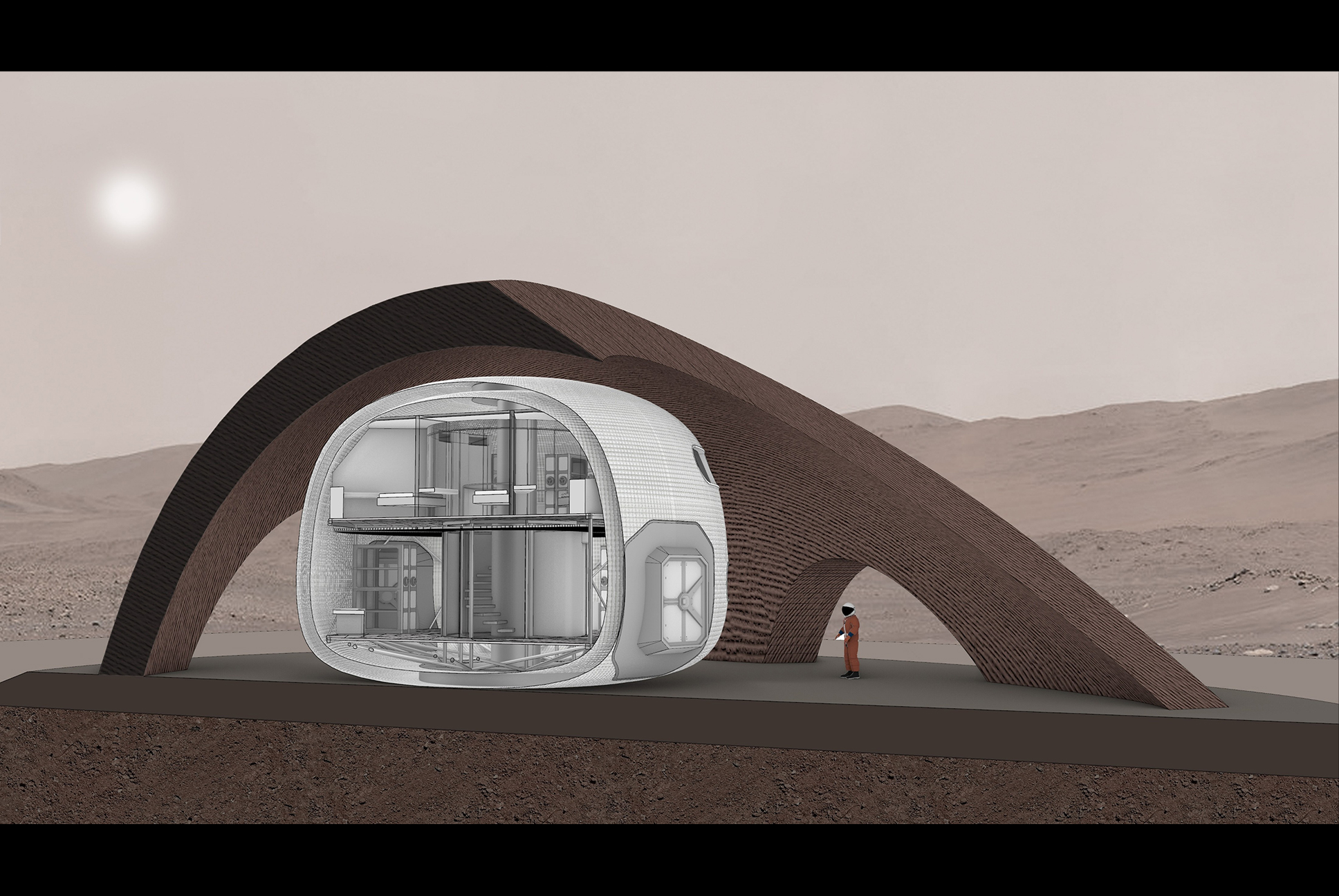

Human habitation on Mars requires infrastructure that can withstand extreme radiation, low pressure, and thermal variation, making traditional construction methods unfeasible. This project explores a scalable approach to automated habitat construction using local materials and autonomous robotics, focused on a theoretical sequence based on decentralized swarm collaboration. Inspired by natural systems, the framework envisions mobile robotic agents performing tasks like terrain analysis and 3D printing. While no swarm prototype exists yet, the work centers on modeling, structural analysis, and partial prototyping to assess the feasibility of Marscrete-based additive construction.

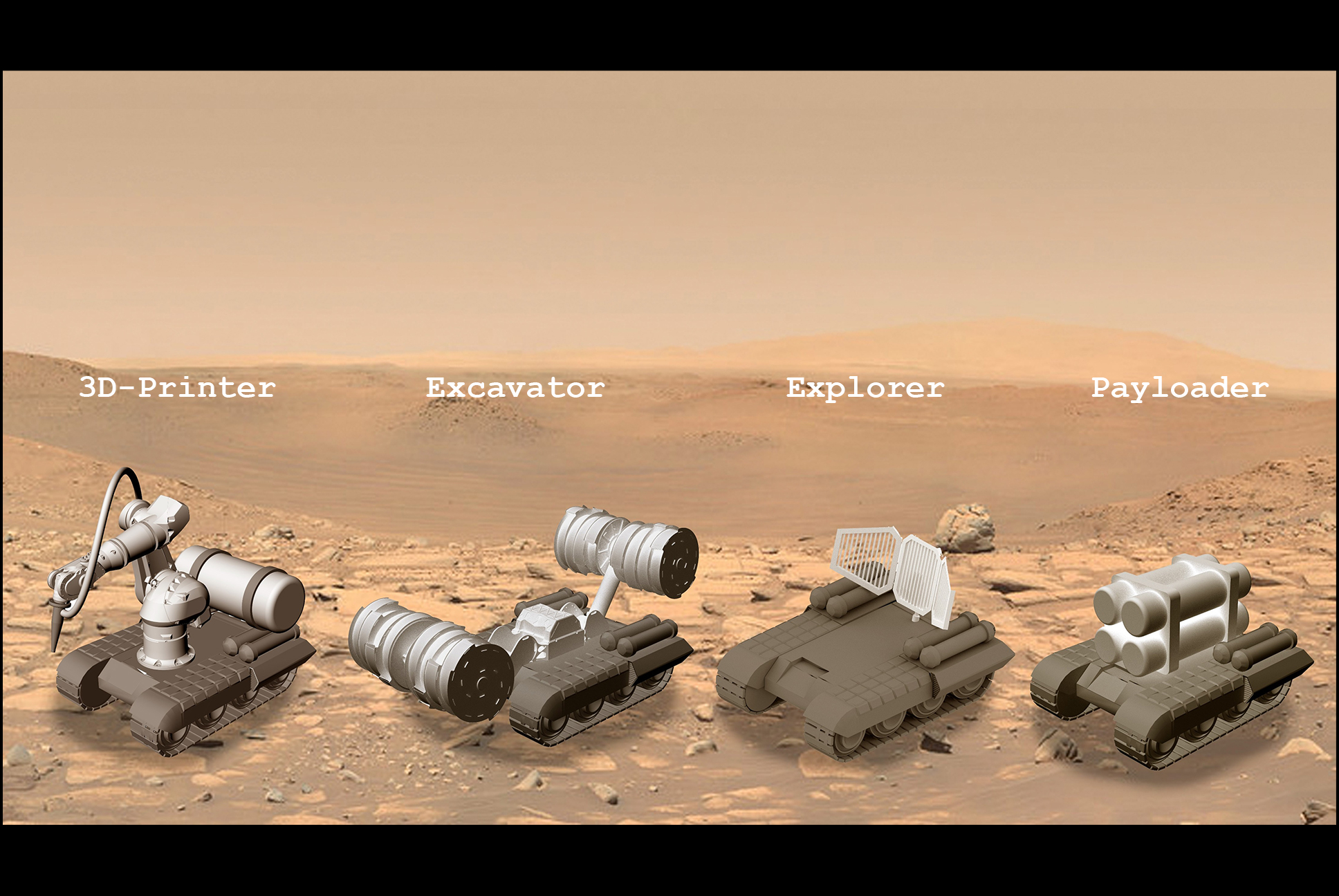

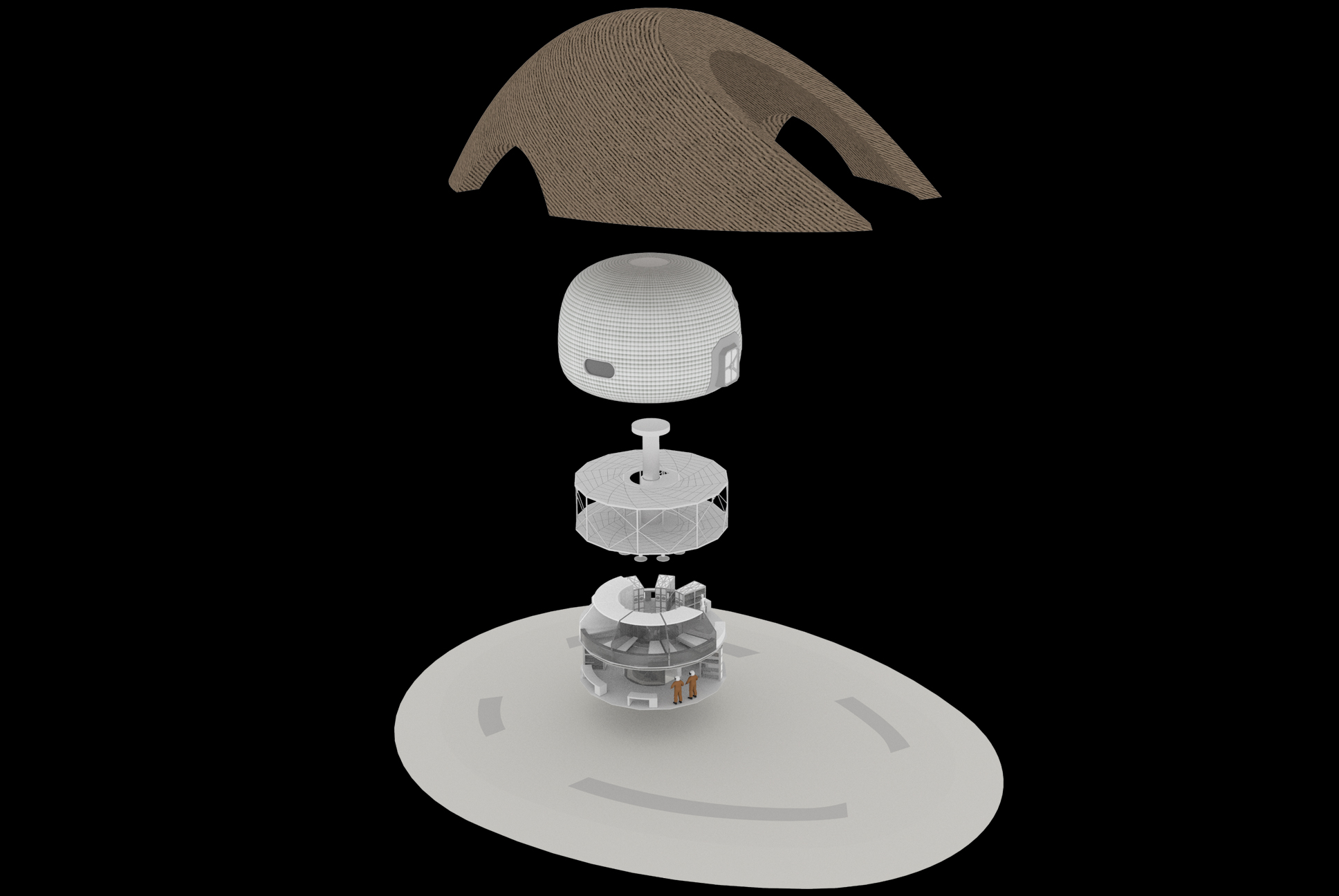

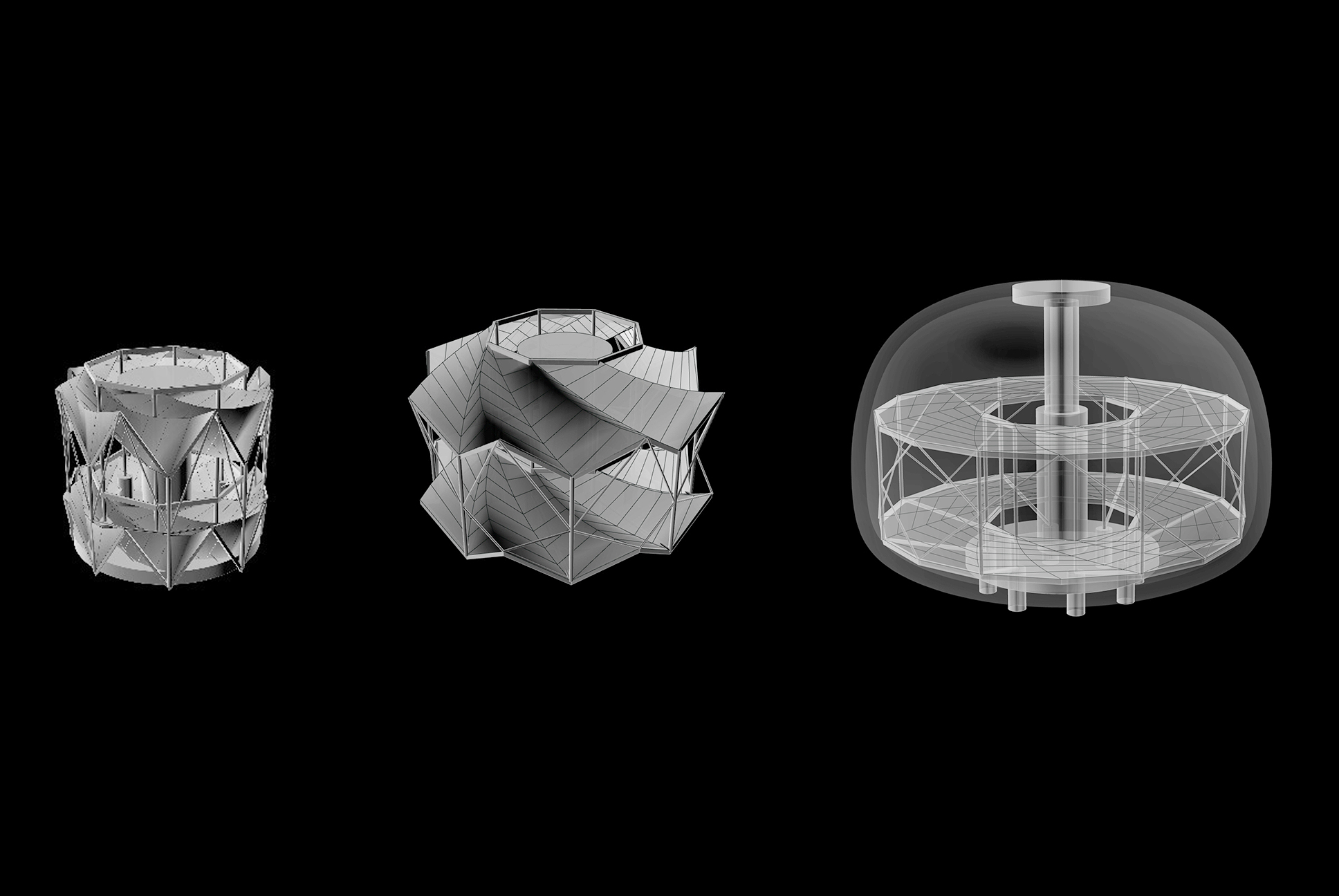

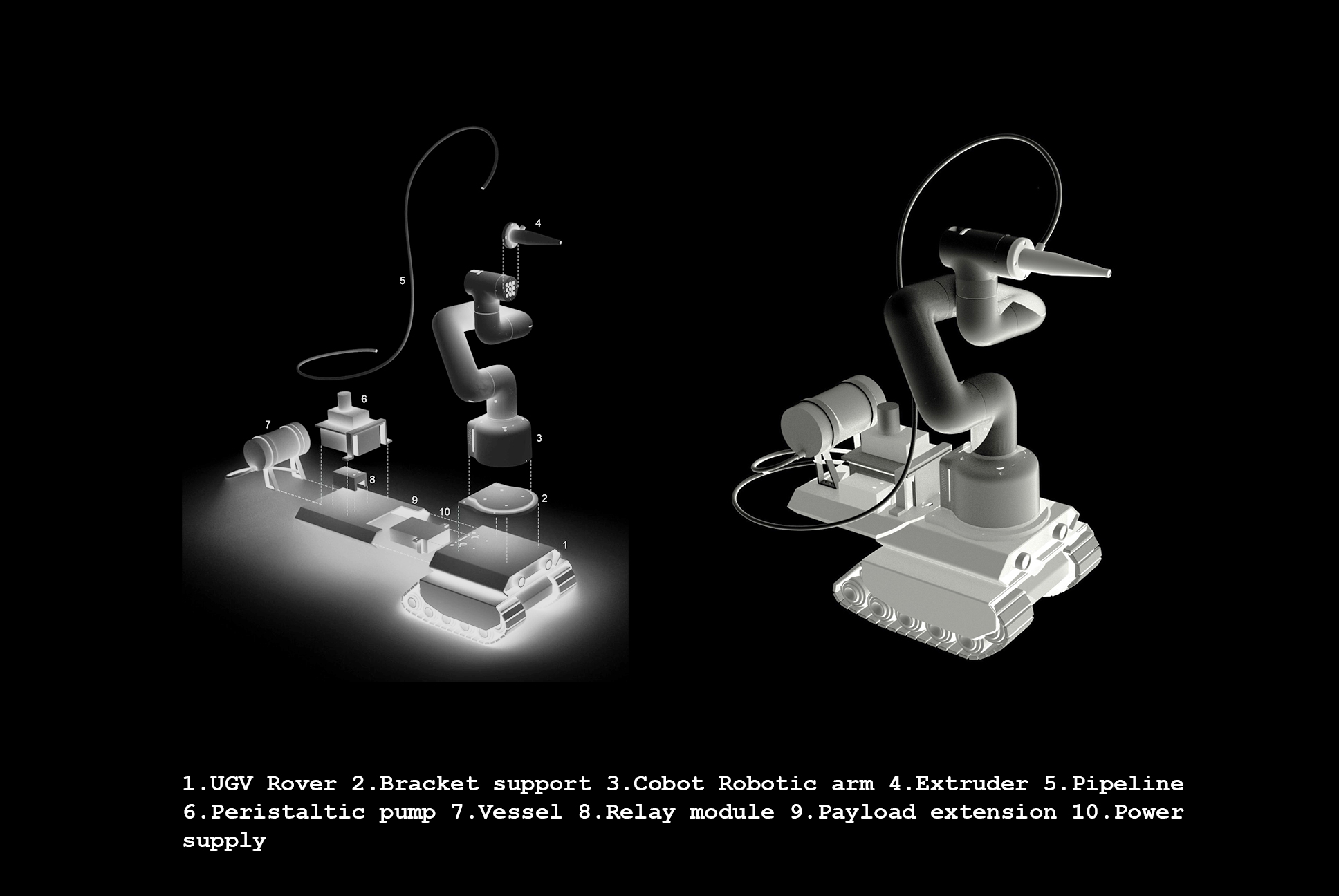

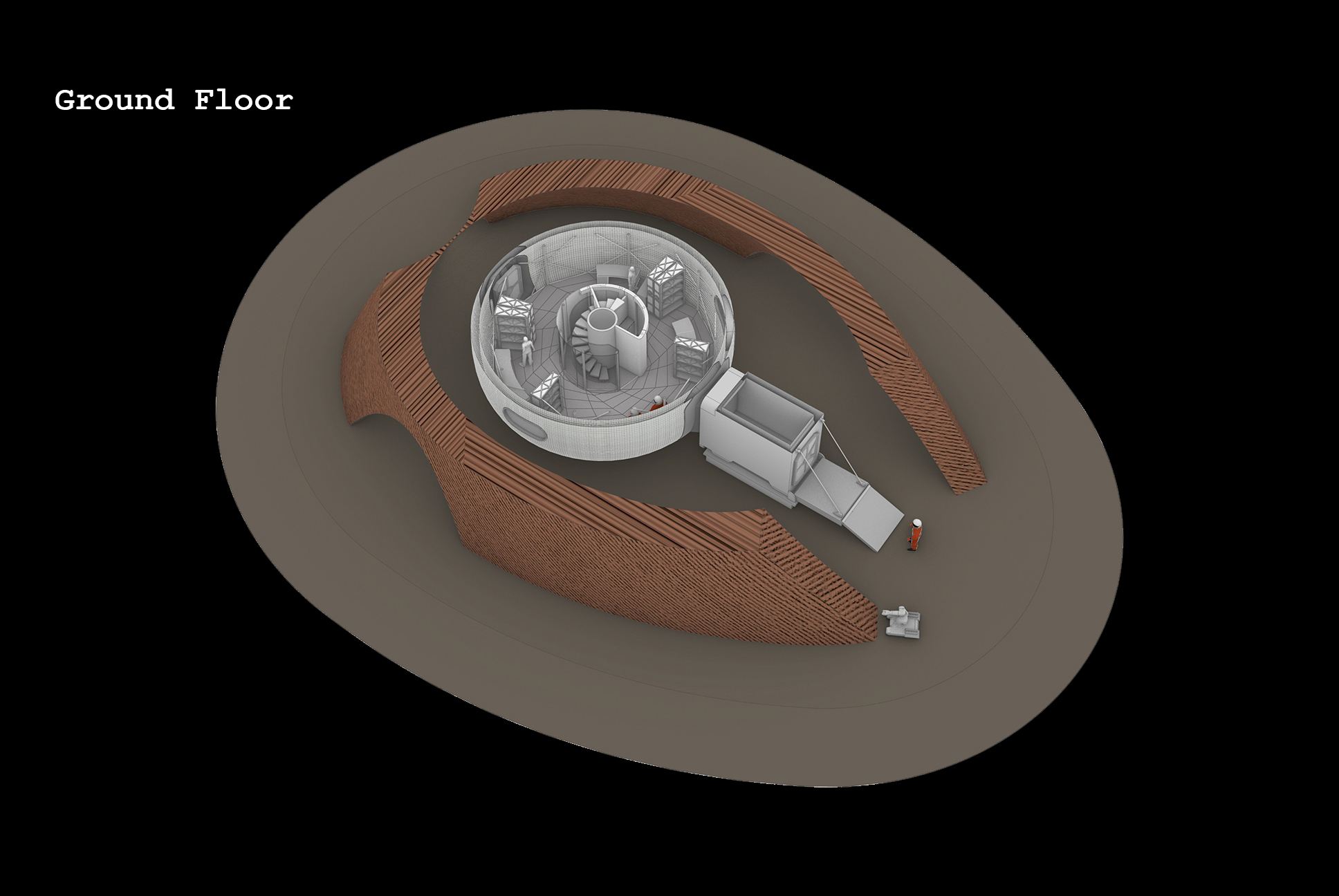

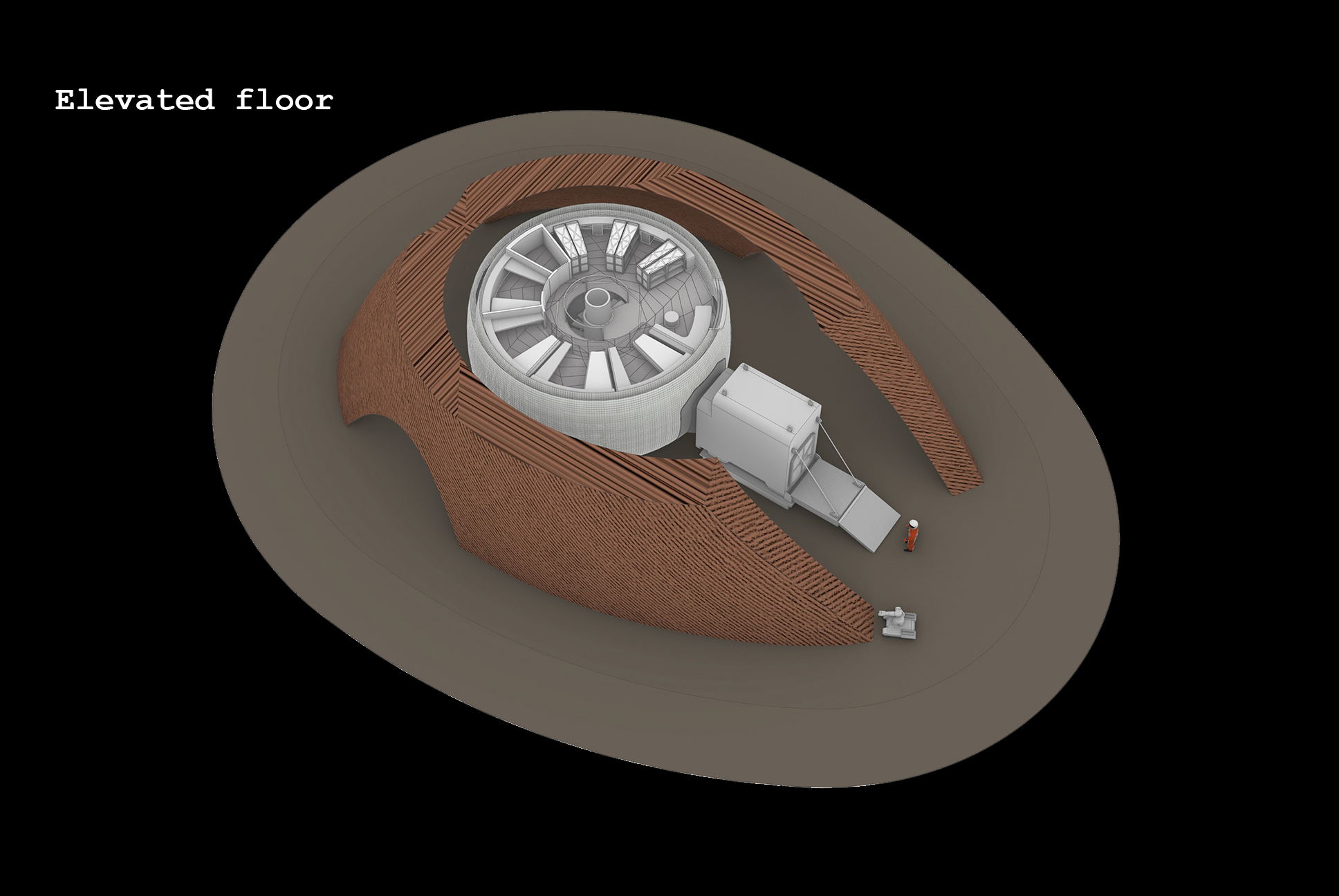

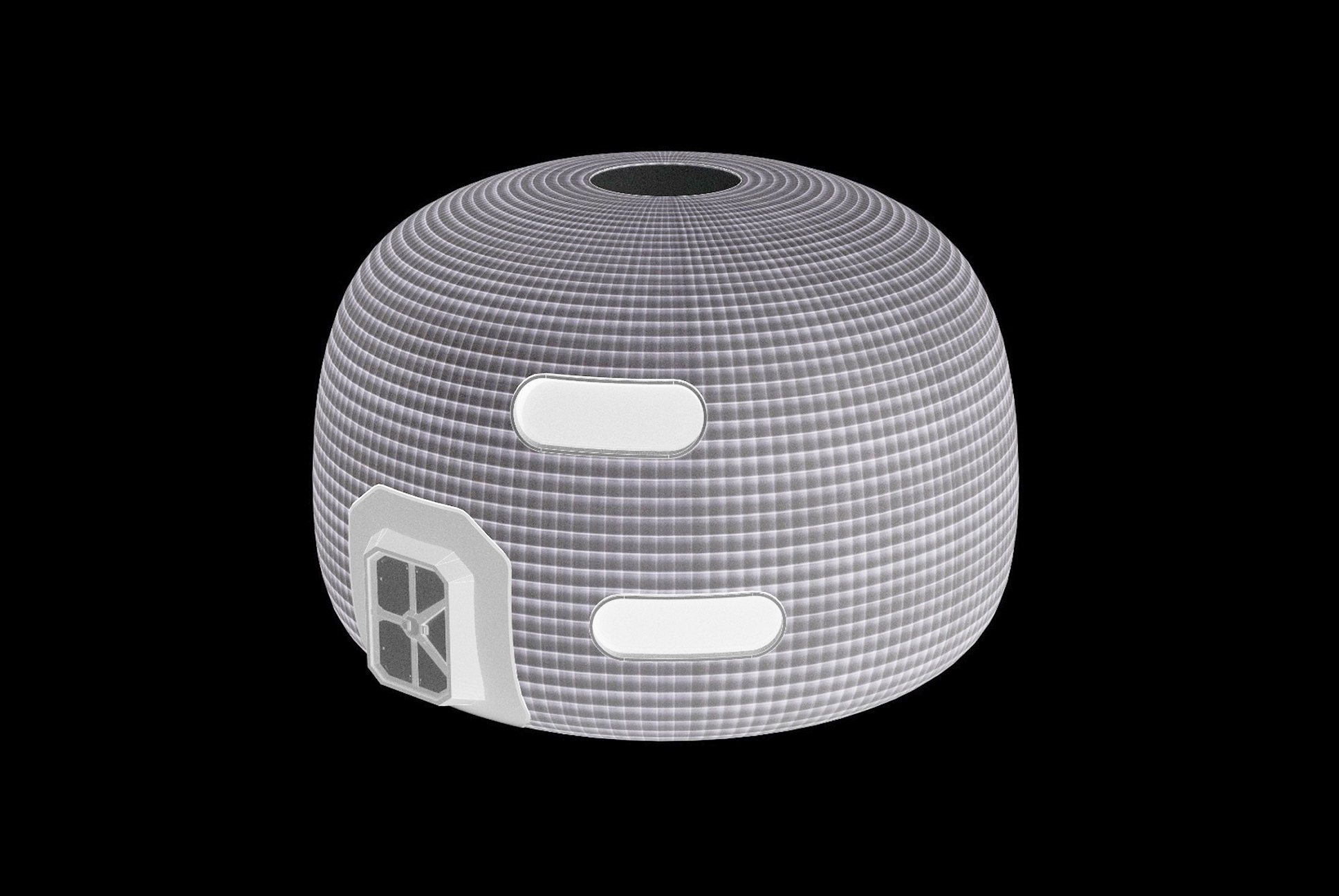

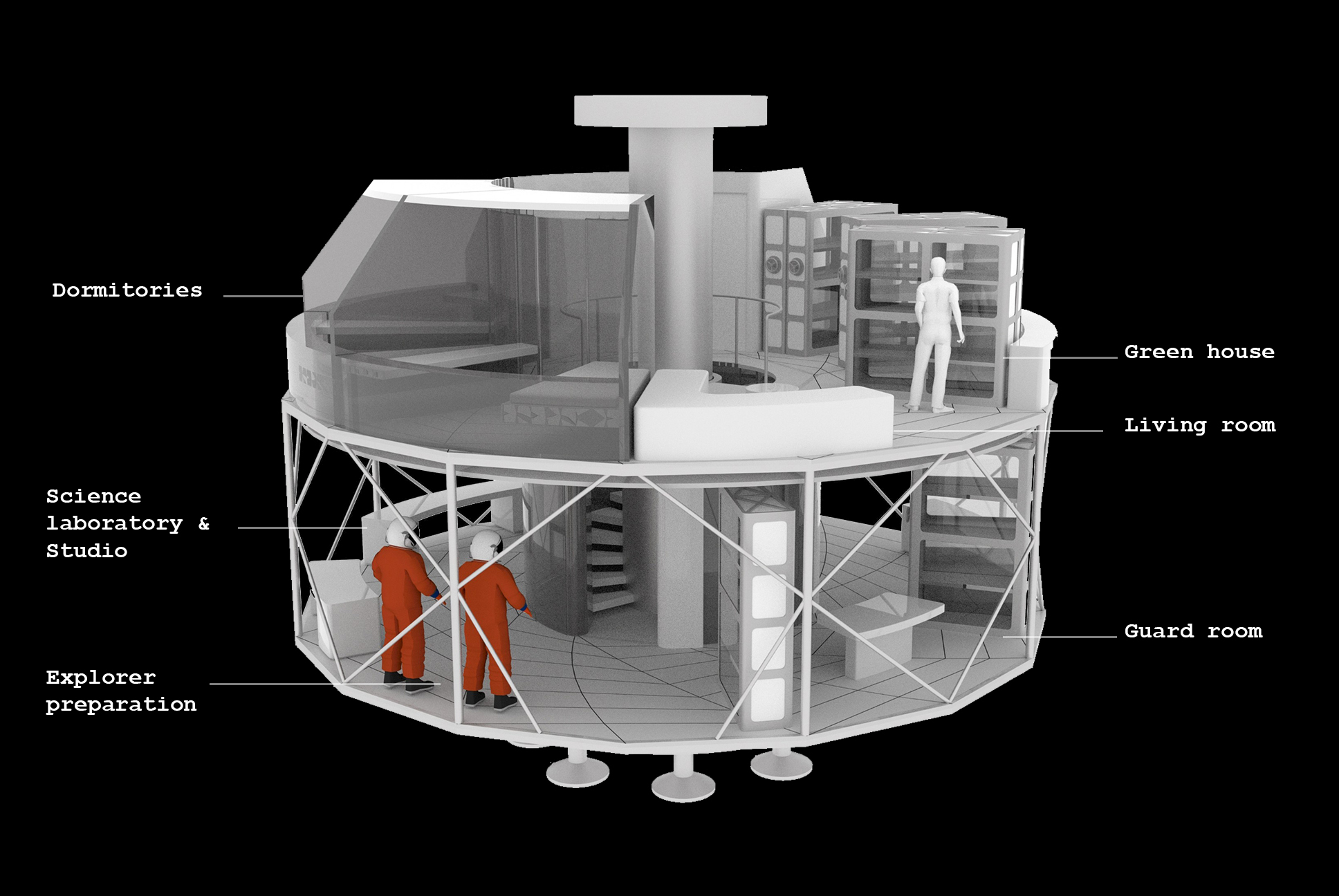

The proposed habitat integrates a deployable inflatable structure, transported from Earth, with an additively manufactured external shell made from Marscrete. The inflatable module features a multilayered membrane for environmental shielding and a rigid internal framework for structural support and spatial organization. The external dome is optimized for compressive loading and radiation protection. Marscrete, a sulfur-regolith concrete requiring no water, is selected for its compatibility with Martian conditions and suitability for thermal-based 3D printing. A prototype printing system was developed using a small rover equipped with a robotic arm, pump, and extruder, with trials conducted using clay and plaster mixtures to simulate extrusion dynamics. While swarm-based construction remains a long-term goal, the current focus is on theoretical exploration, using algorithmic models to study distributed task execution, local sensing, and decentralized control.

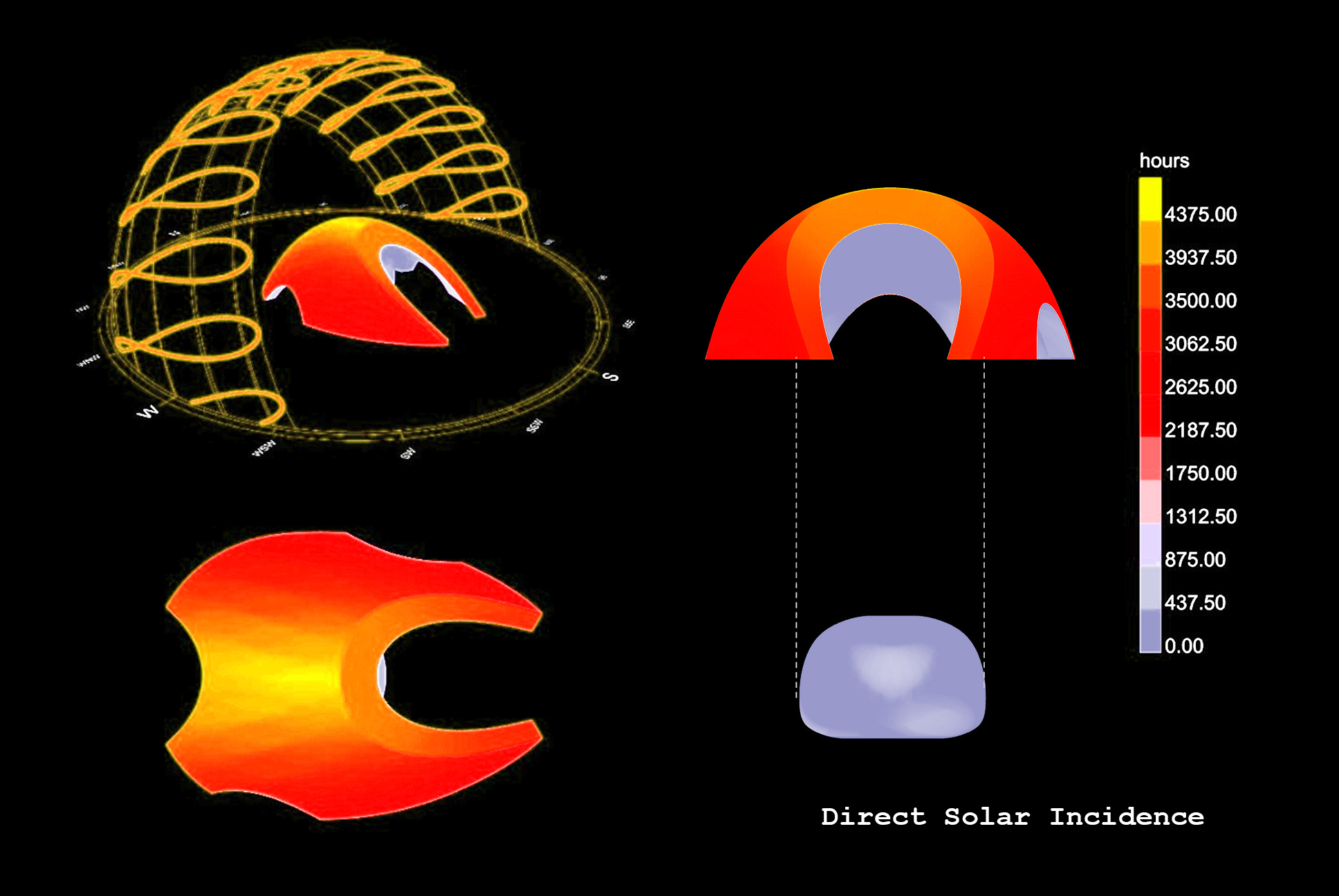

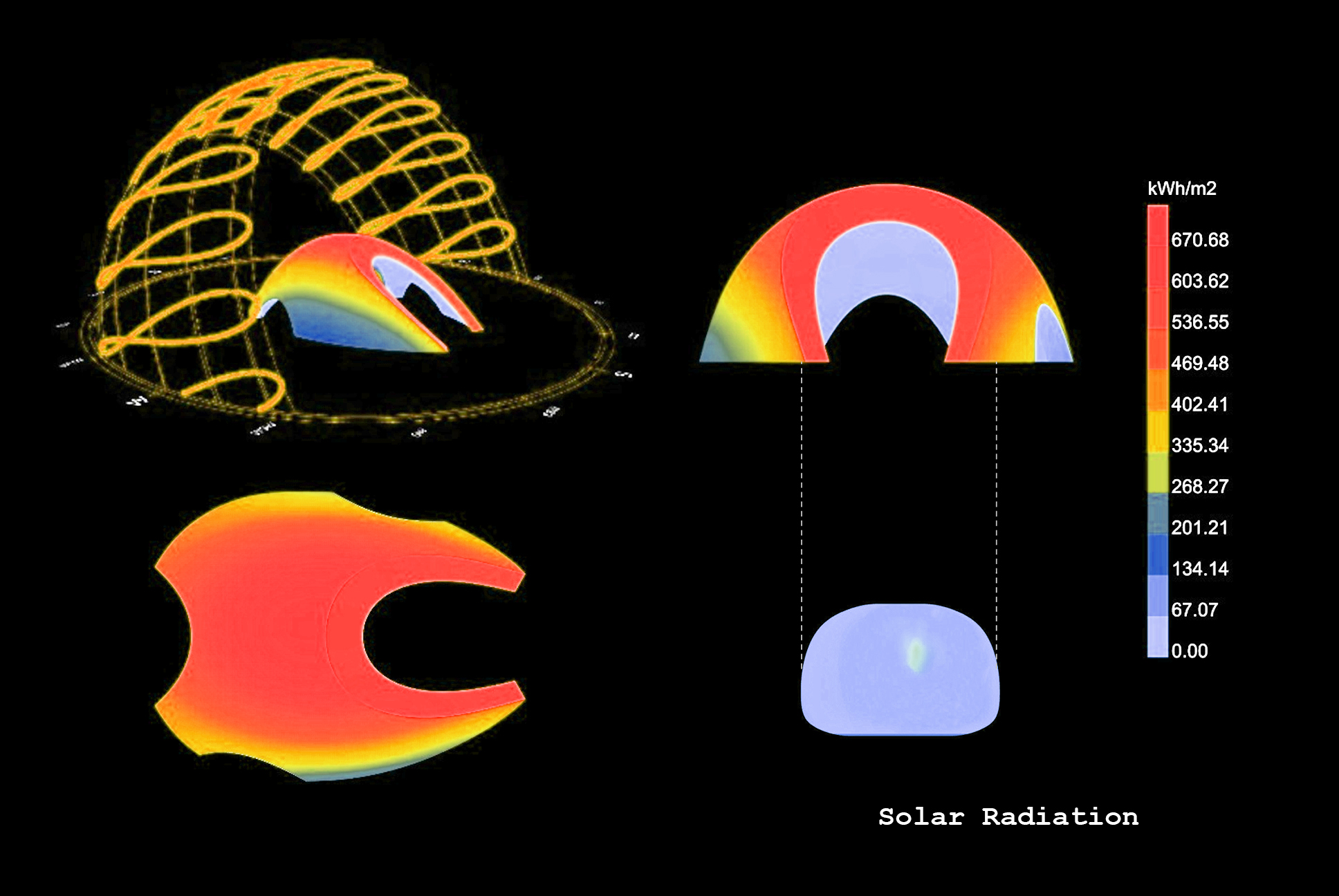

The system successfully printed a small dome using a fluid clay mixture, demonstrating effective coordination between rover movement and material deposition. Plaster proved less suitable due to clogging and settling, revealing material limitations. Structural analysis, adjusted for Martian gravity, confirms that dome geometries can efficiently support compressive loads when built with Marscrete. Solar radiation analysis, based on Atacama Desert analog data, indicates that the printed shell significantly reduces exposure, though some areas remain partially vulnerable. These insights led to minor geometric refinements to enhance shielding performance.

space

MATERIALS

Marscrete | Clay

PROCESSES

3D Cement Printing (3DCP) | Robotic 3D-Printing | Autonomous Construction Equipment

DESIGNS

Deployable Structures | Dynamic Relaxation | Variable Stiffness Structures

space

ROLES

Indexlab led the R&D for a speculative project envisioning a habitat on Mars. The work included designing and prototyping a robotic 3D printing system, combining a mobile rover and a robot capable of autonomously navigating rough terrain and constructing protective structures.

STAKEHOLDERS

LOCATION

INDEXLAB - Politecnico di Milano, Polo Territoriale di Lecco, Lecco, Italy

YEAR

2025

space