TWIST

Kinetic façade system using motorized metal blades to create dynamic, programmable architectural displays

This project presents a dynamic kinetic facade aimed at transforming passive architecture into an engaging, visual spectacle. Addressing the challenge of creating identifiable yet subtle kinetic patterns, the installation employs synchronized motion across hundreds of twisted metal blades. Each blade moves independently, driven by stepper motors controlled via an intuitive web-based interface. Preliminary results indicate substantial visual engagement, simplified operational management, and robust system reliability, laying the groundwork for future scalable implementations.

The main objective is to design and implement a kinetic facade that visually captivates travelers through choreographed movements discernible from significant distances. Within contemporary architecture, kinetic facades enhance user experience by combining aesthetic appeal and interactivity, often transforming static structures into dynamic displays.

Current literature underscores kinetic architecture’s potential to improve spatial interaction and visual perception. This project’s specific objectives include creating visually appealing yet subtle motion patterns, enabling operational independence for non-technical users.

The installation consists of individually motorized metal blades, each representing a digital unit with individual control parameters.

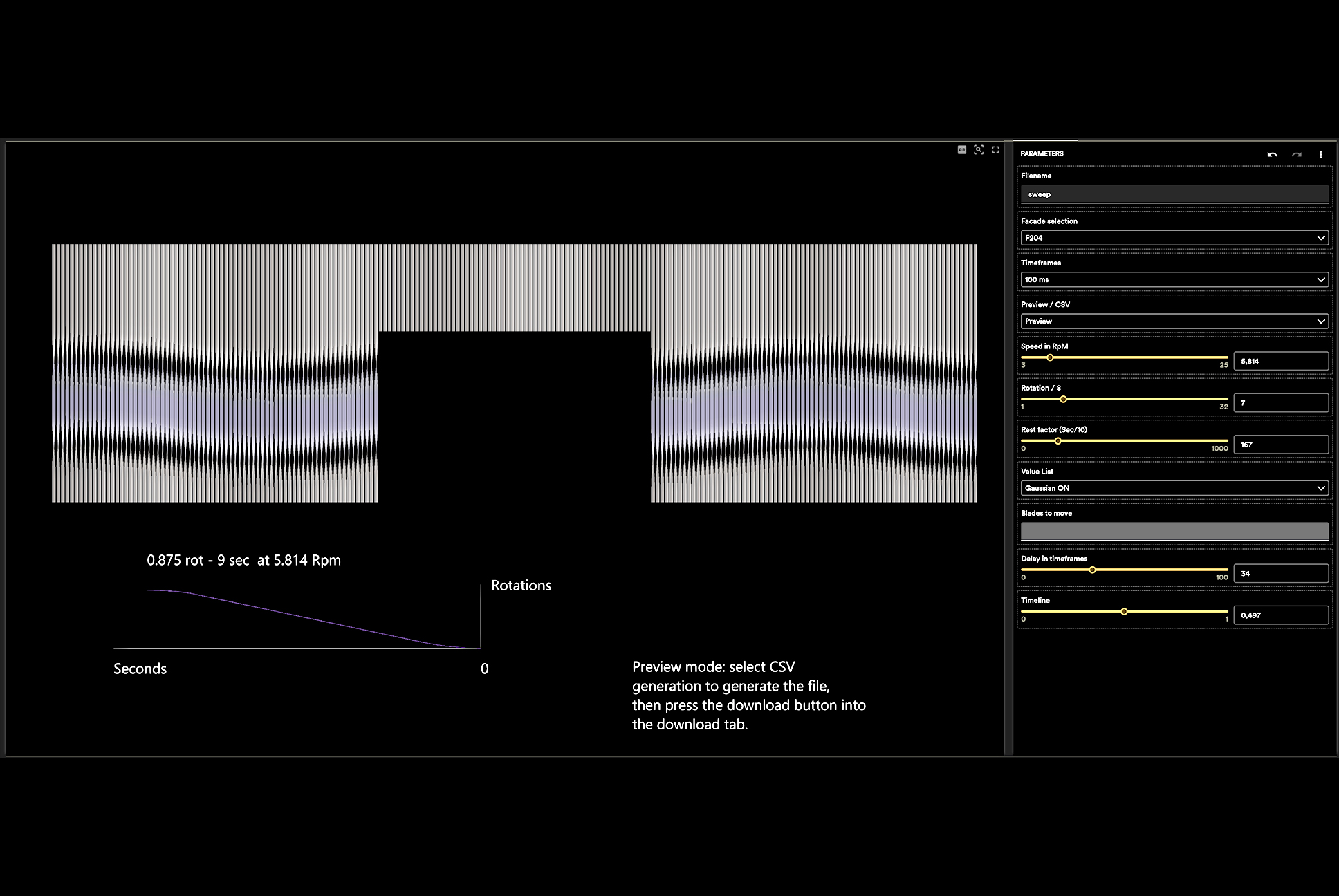

A web-based configurator allows operators to set choreography parameters, such as rotation speed, duration, spatial distribution, and timing sequences. The configurator automatically generates two outputs: a detailed motion control script formatted as a CSV file specifying incremental angular movements, and a high-resolution preview video for immediate visual verification.

After approval, the control file transfers to an industrial-grade automation system running EtherCAT I/O, managing real-time synchronization of blade movements. The installation operates in open-loop mode, recalibrated daily via a manual reset protocol to maintain positioning accuracy.

Initial deployment demonstrates significant visual engagement. At low rotational speeds, the installation exhibits sculptural qualities, transitioning to a dynamic visual effect at higher velocities.

Operational flexibility allows choreography durations from several seconds to approximately two minutes, adjustable through an accessible interface.

Daily operations confirmed ease of use, with store personnel independently managing routine updates without technical intervention.

space

MATERIALS

Steel | Aluminum | Digital Materials

PROCESSES

Twisting | MicroProcessor | Stepper Motors

DESIGNS

Twisted Surfaces

space

ROLES

.

STAKEHOLDERS

LOCATION

.

YEAR

2023

space