TIMBOT

Robotic pick-and-place system combining CNC milling and modular assembly for complex wooden façades

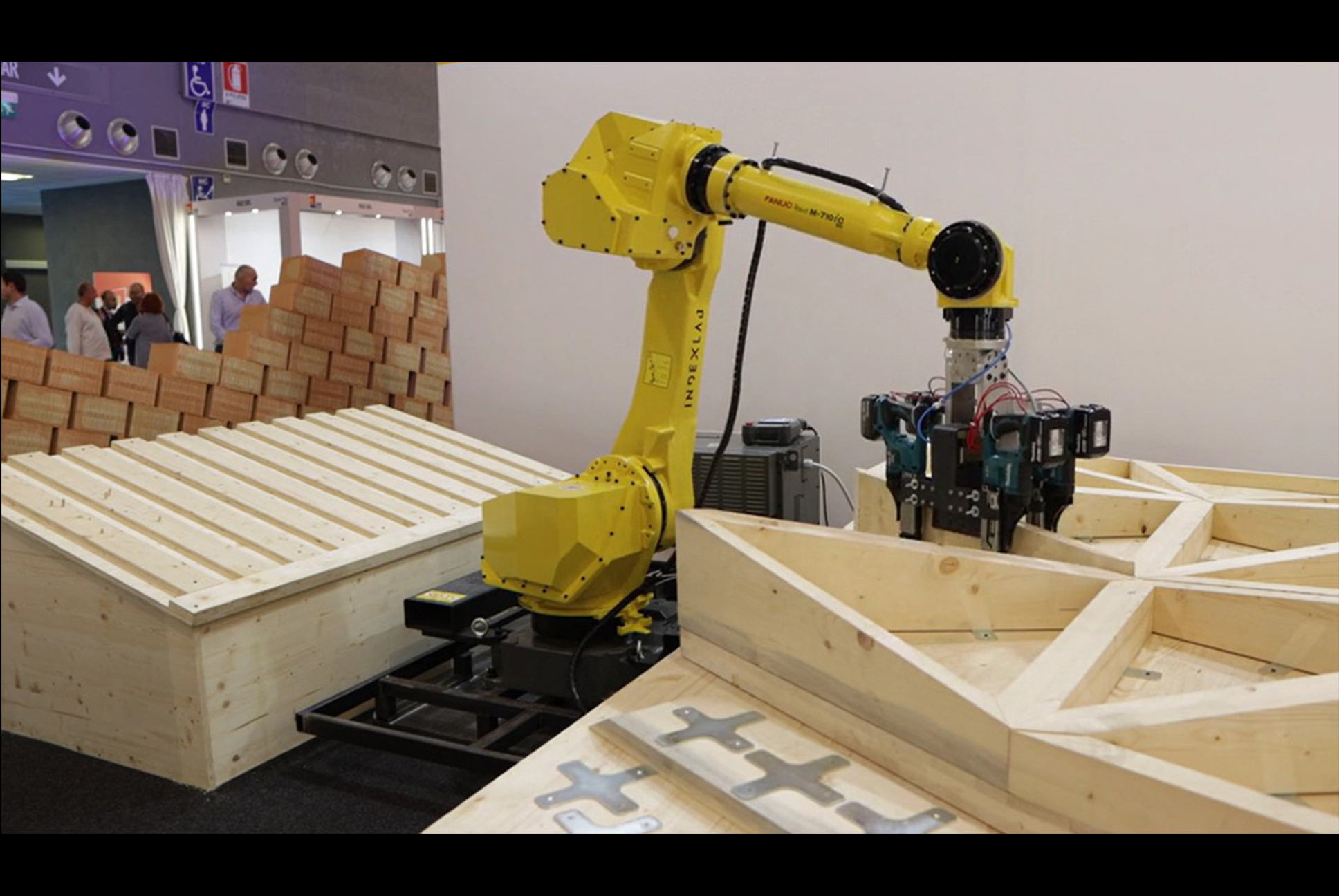

TIMBOT is an innovative semi-automated construction system for the prefabrication of wooden façades. It combines uniquely shaped, self-supporting structural elements with a hybrid fabrication approach that integrates laser cutting, CNC wood milling, and robotic assembly. Timbot demonstrates that when complex geometries are paired with a simple, structured methodology, high-aesthetic-value outcomes can be achieved at competitive production costs.

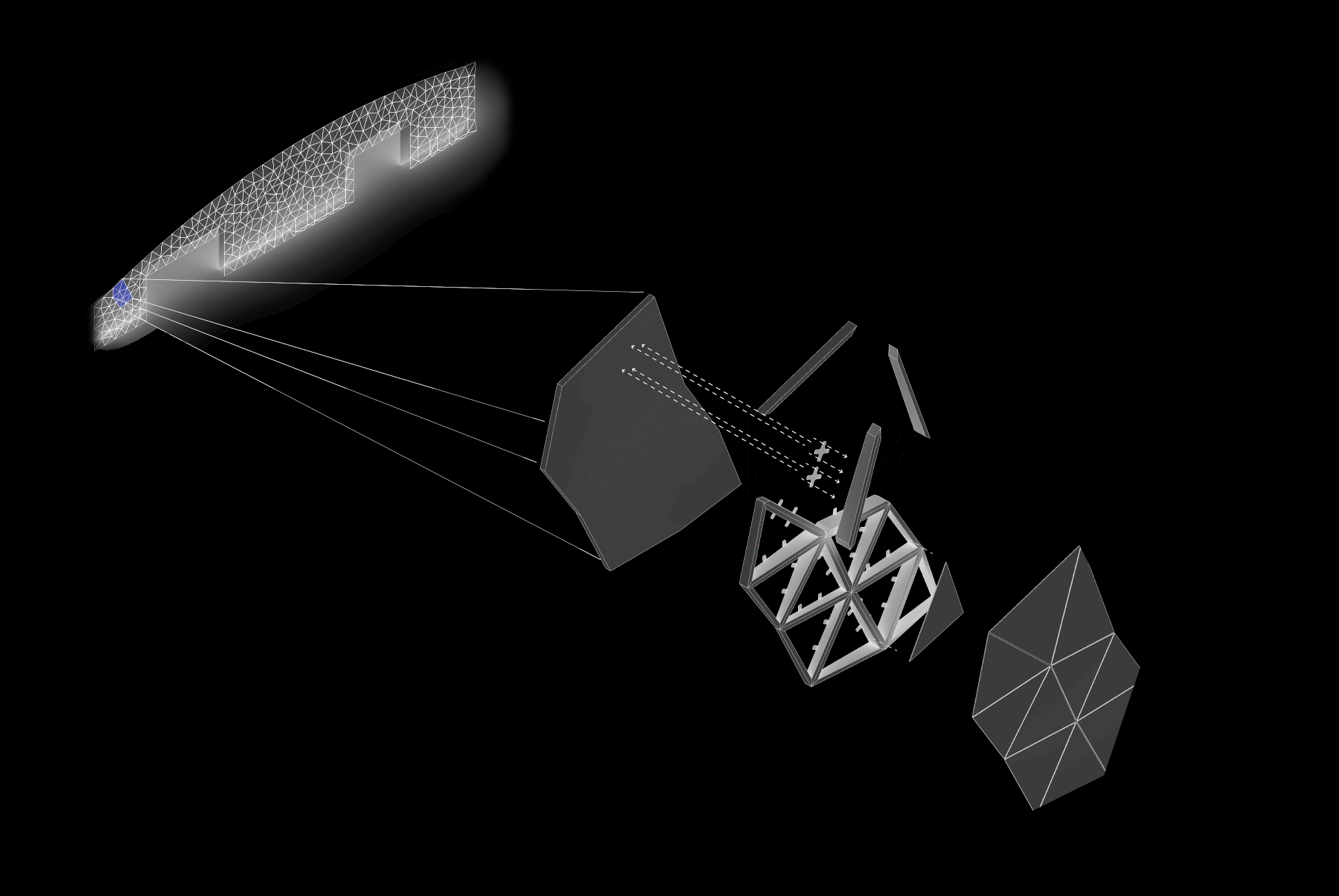

Computationally, the project addresses the segmentation of a triangulated façade into micro-modules. Fabrication-wise, it focuses on efficient assembly of both the substructure and the load-bearing timber panels. Robotic adaptability is a core consideration, enabling the handling of non-repetitive elements without the need for manual tracing or measurement. Instead, components are pre-labeled and positioned using a robotic arm operating within a unified digital coordinate system.

wo key elements are prepared before assembly: the base panel—a CNC-cut timber fragment of the façade—and the substructure, composed of repeated linear elements. These elements have a five-sided cross-section designed to follow the façade’s geometry: a U-shaped base with two pitched upper surfaces, enabling the attachment of triangulated panels.

Each element is fitted with two cross-shaped steel plates, each with four countersunk holes. Two holes are aligned longitudinally to secure the plate to the element; the other two are perpendicular, allowing the combined unit (element + steel plate) to be fixed to the timber base.

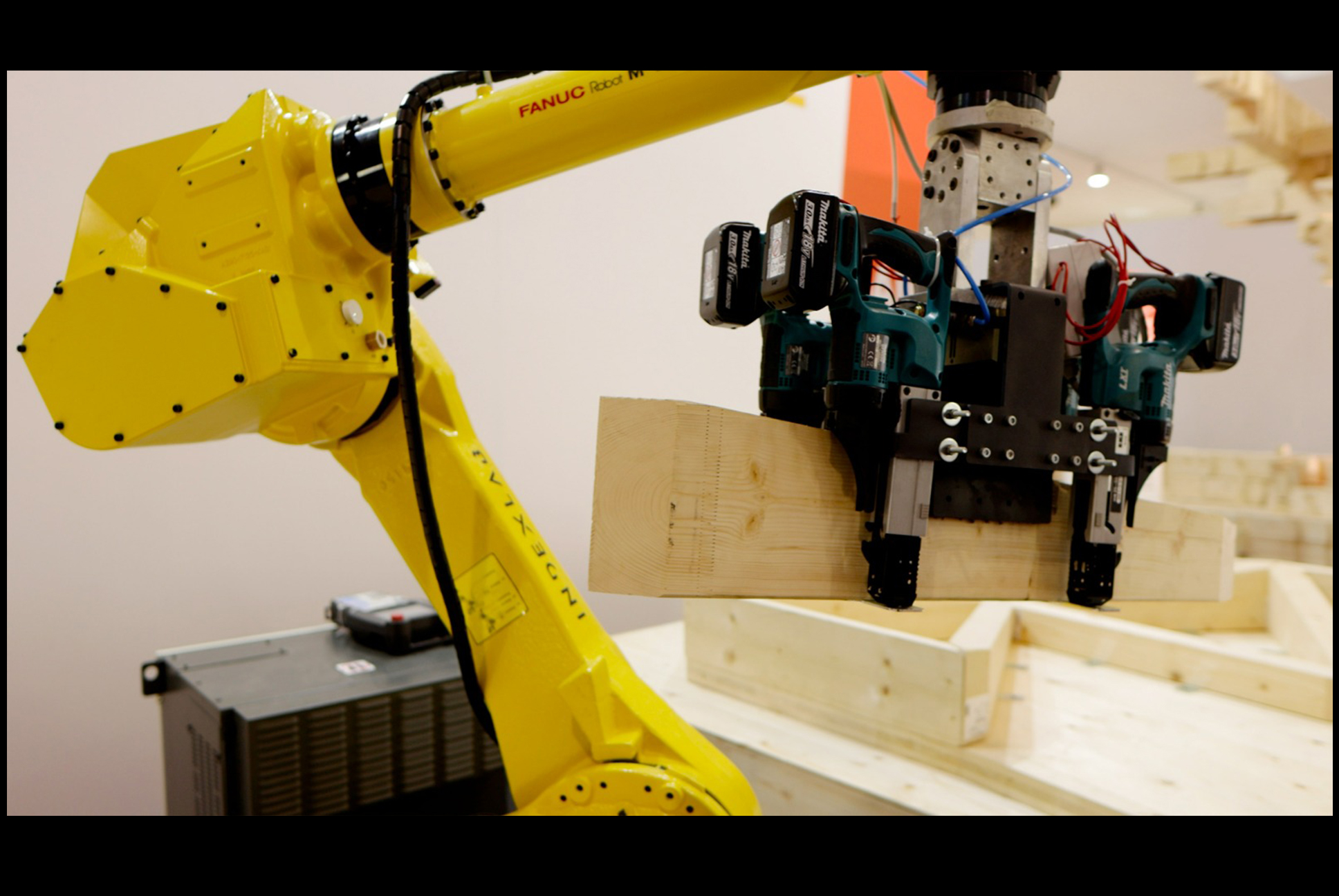

Assembly is executed using a robotic end effector that integrates a gripper and four screwdrivers. The gripper handles precise placement, while the screwdrivers fasten the elements directly to the base panel.

Timbot delivers an efficient and precise solution for assembling mesh-like façade skins composed of unique parts. It eliminates the need for preparatory steps like manual labelling and layout tracing, streamlining the workflow through robotic positioning based on digital design data.

space

MATERIALS

Cross-Laminated Timber (CLT) | Steel

PROCESSES

CNC Milling | Laser Cutting | Screws | Robotic Pick and Place | Robotic Screwing | Prefabrication and Modular construction

DESIGNS

Triangulation | Kit-of-Parts Modular Systems

space

ROLES

Indexlab led the R&D for TIMBOT, developing the concept of robotic manipulation through custom interface plates. The team designed and built a specialized end-effector capable of gripping, positioning, and screwing different wooden beams onto a flat CLT surface in a single phase.

STAKEHOLDERS

LOCATION

First exhibited at SAIE Fair in Bari, Italy

YEAR

2023

space