LOKALP

Discrete construction system using dry-joint blocks, robotic milling, and AR-guided assembly

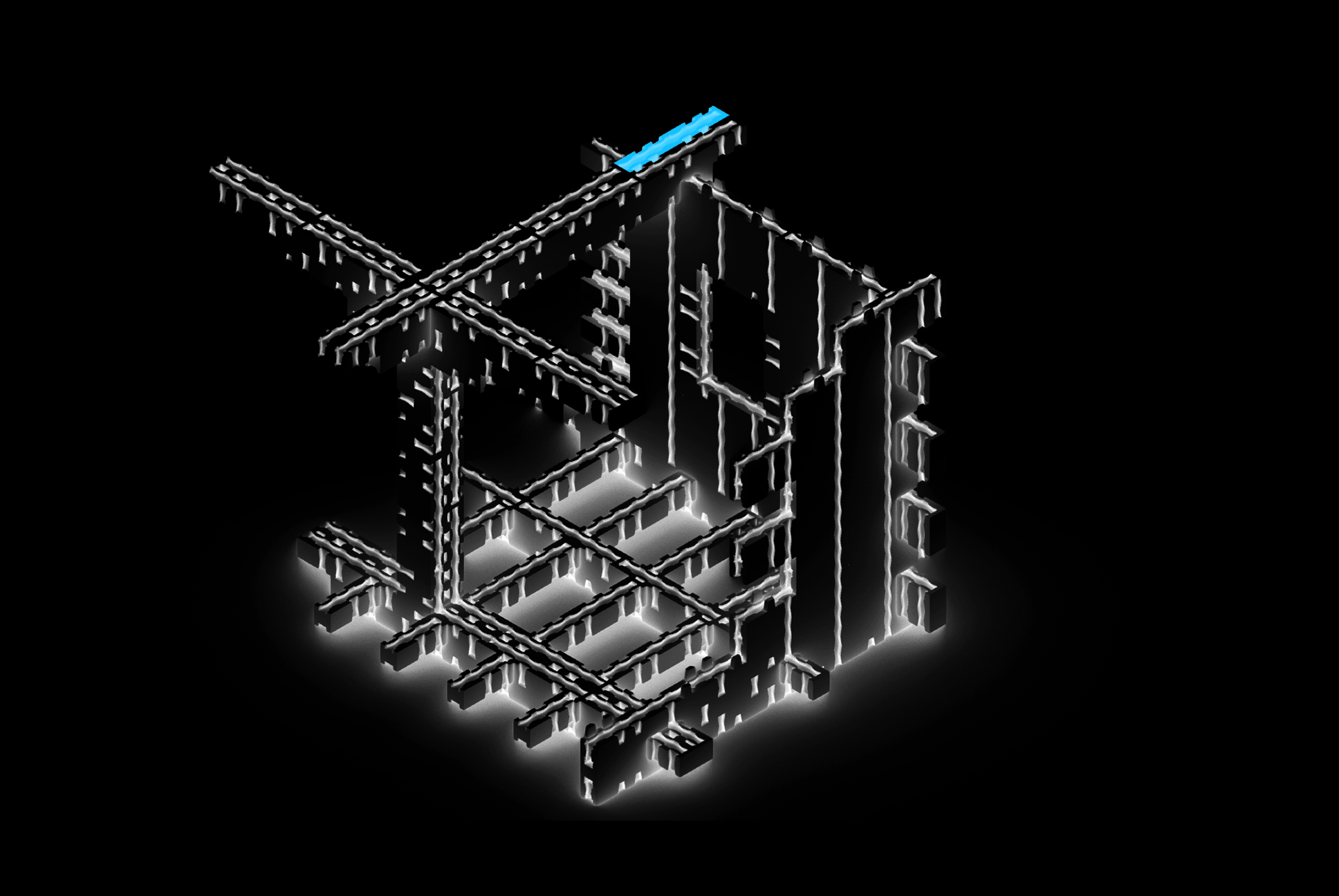

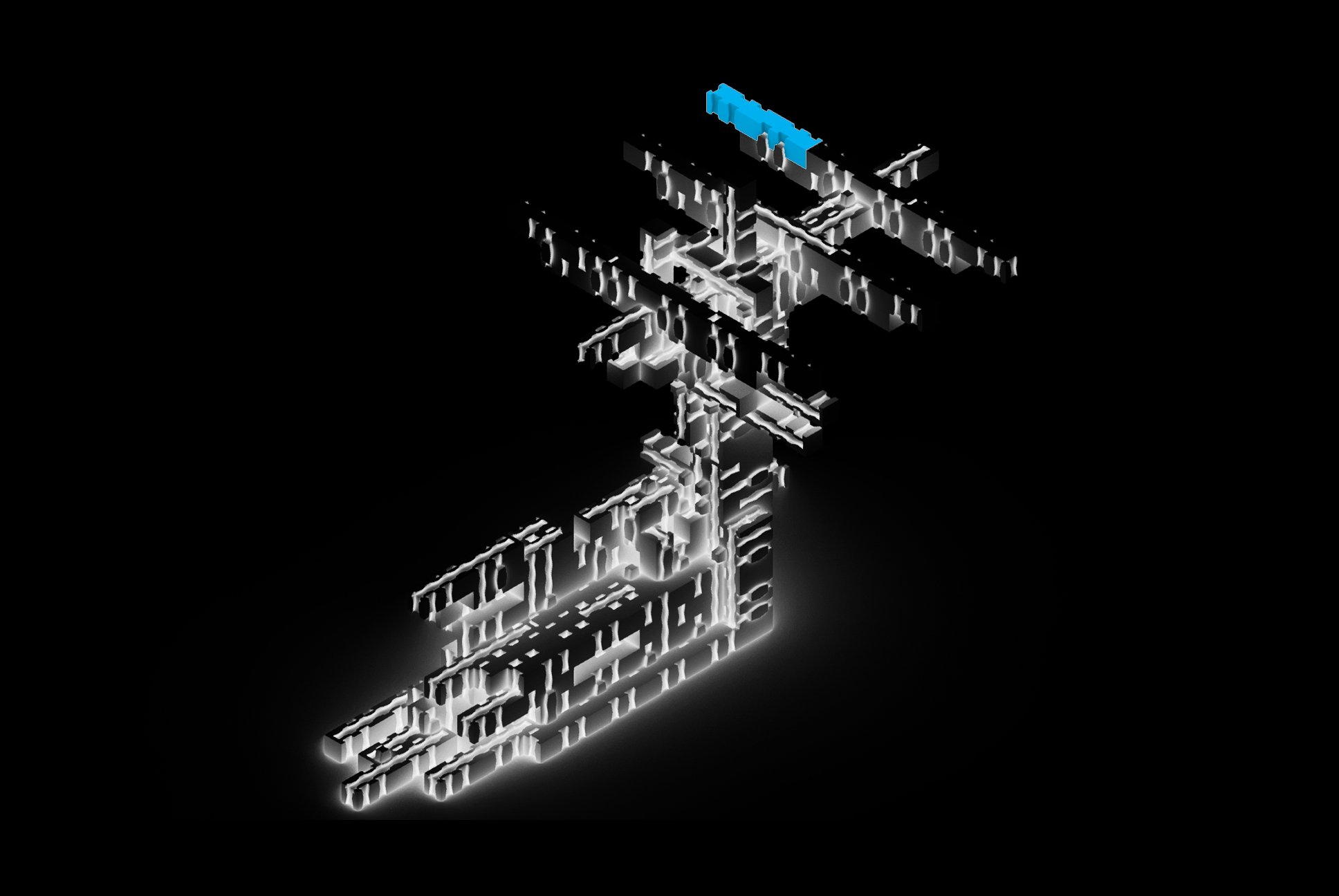

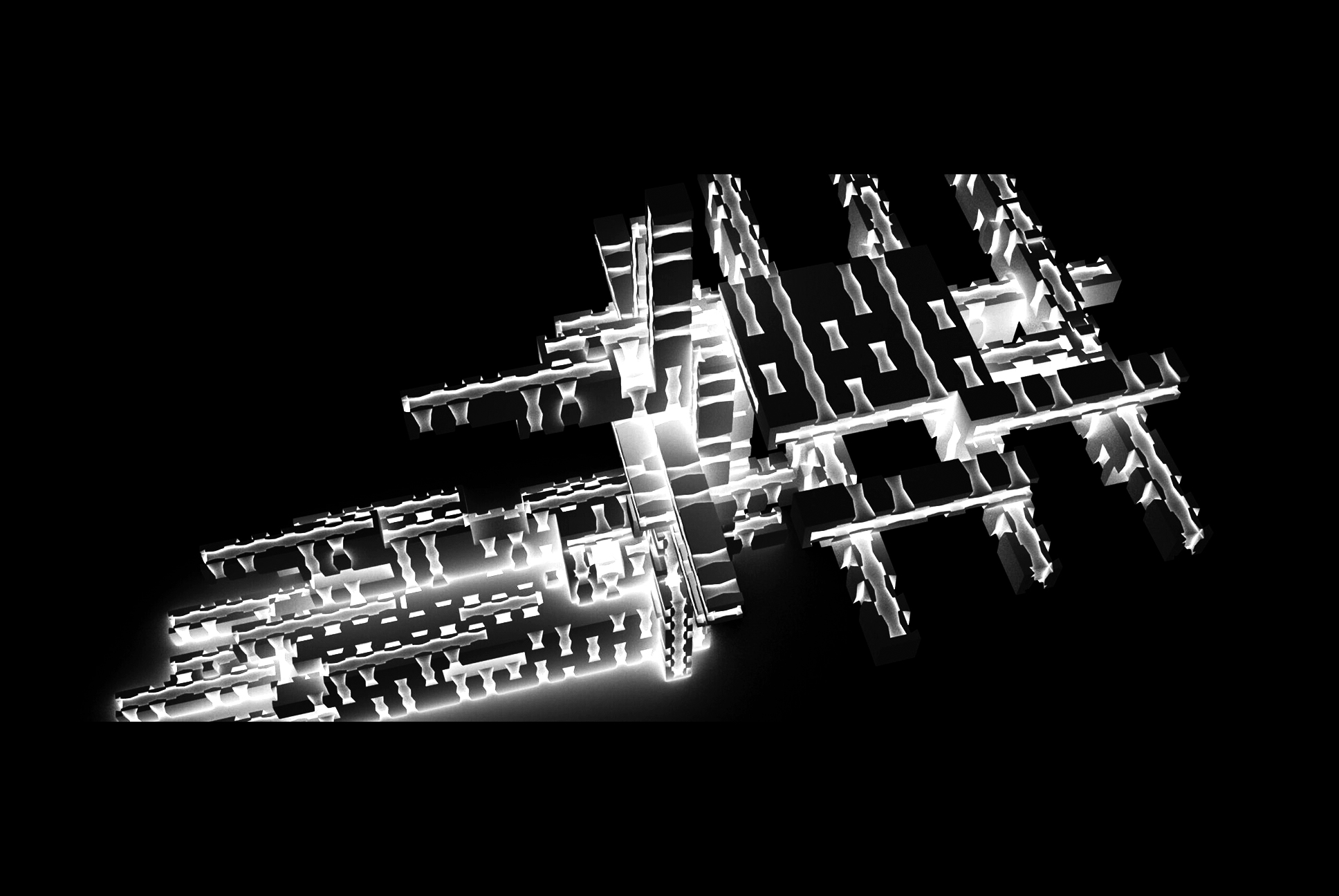

LOKALP is an innovative discrete construction system based on universal dry-joint blocks, combining generative design with digital fabrication. The patented system has demonstrated that the use of Augmented Reality glasses can significantly reduce construction time and on-site errors. Furthermore, the use of robotic arms in the manufacturing process can cut production time by up to 56% compared to traditional methods.

LOKALP aims to demonstrate a more valuable reuse of by-products from the CLT industry, offering an alternative to traditional incineration. Architecturally, LOKALP seeks to provide a universal, deconstructable building system that does not limit future design possibilities for architects who will reuse its components. A key challenge is to maximize compositional freedom while minimizing material waste generated during the milling process.

The system is designed to be compatible both with traditional production methods used in the timber construction industry—such as Hundegger CNC cutting centers—and with flexible, innovative robotic-based fabrication systems. In this case, the actual production was carried out using CNC technology. This dual compatibility ensures high adaptability across different manufacturing contexts, making the process scalable for both standardized industrial environments and advanced fabrication laboratories.

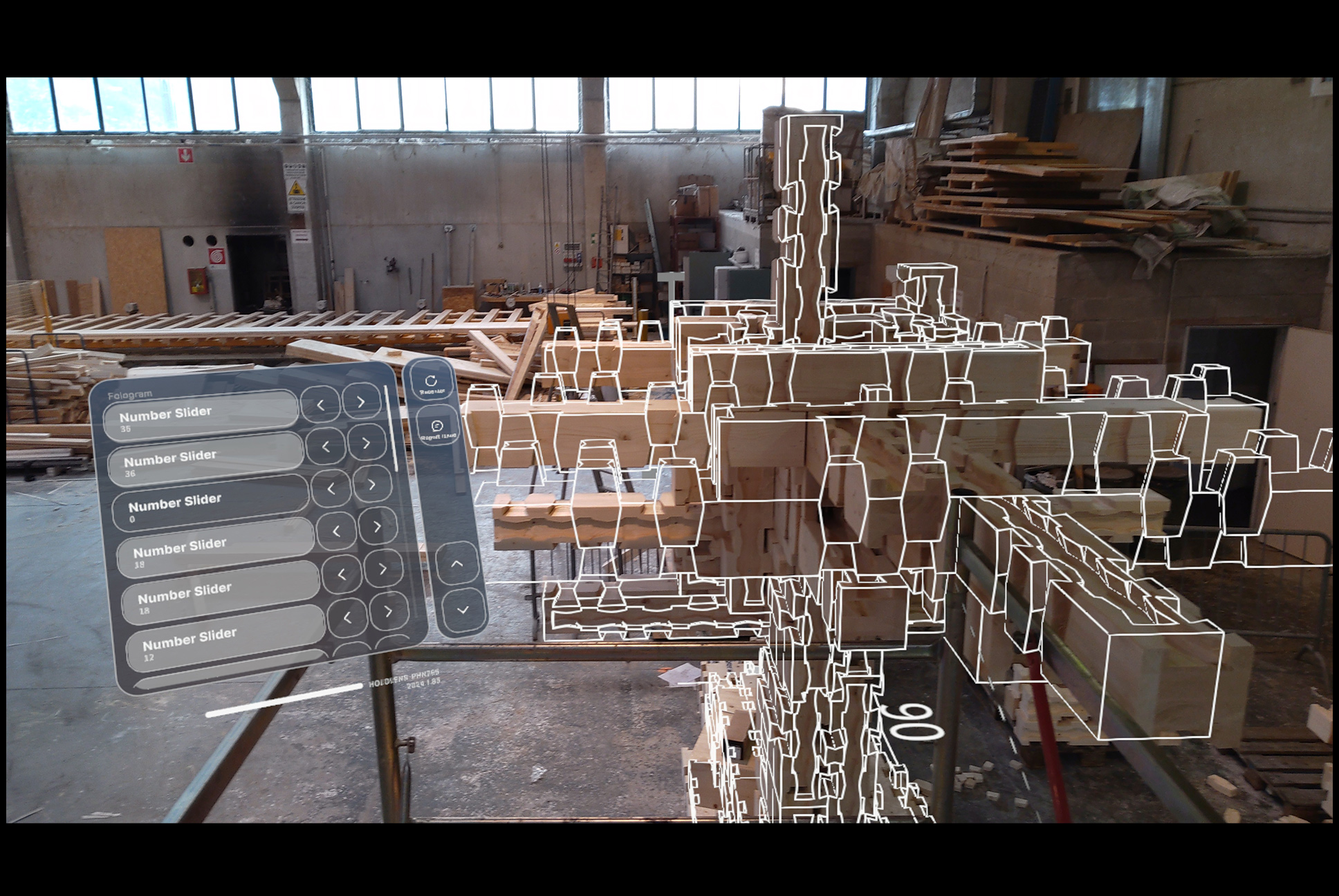

The simulated robotic fabrication process is based on a 6-axis robot, a centering platform, and a dovetail milling table. The material used is a CLT block measuring 160×160×960 mm. The robot grips the wooden block using a mechanical gripper, places it on the centering platform, and then performs planar toolpath milling on one of the six faces. After completing one face, the robot repositions the component on the platform to change the gripping side. This cycle is repeated for all six faces of the component. Once production is complete, assembly is carried out by a human operator using Augmented Reality glasses. Three printed QR codes are placed on the floor for tracking. Through a pre-written script, the operator can visualize each construction step in chronological order.

LOKALP enables a more efficient and sustainable reuse of by-products from the CLT industry, reducing emissions while offering greater design freedom for architects. Robotic simulation has shown a production time reduction of up to 56% compared to traditional methods. Additionally, the use of Augmented Reality glasses has demonstrated significant benefits in terms of assembly time and complexity management.

space

MATERIALS

Cross-Laminated Timber (CLT) | Digital Materials

PROCESSES

Milling | Dovetail Joints | Robotic Pick and Place | Robotic Wood Processing | Prefabrication and Modular construction | Augmented Reality

DESIGNS

Interlocking Systems | Discrete Part-Based Modularity

space

ROLES

Indexlab invented the construction system and production process behind Lokalp, a patented discrete assembly method based on universal dry-joint blocks. The team developed both the hardware and software components, including the programming of robotic workflows and the implementation of an augmented reality interface that links digital twins with physical assembly.

STAKEHOLDERS

LOCATION

First exhibited at SAIE Fair in Bari, Italy

YEAR

2023

space