STRAINFORM

Robotic sheet forming system for mold-free fabrication of complex architectural geometries

This research investigates the use of Single Point Incremental Forming (SPIF) for producing complex architectural elements without relying on traditional dies or molds. By integrating computational design, custom toolpath generation, and robotic fabrication, the project explores how SPIF can enable the digital manufacturing of freeform geometries. The methodology focuses on adapting this flexible forming process for architectural applications through controlled experimentation and rationalized fabrication workflows.

SPIF enables mold-free fabrication of complex architectural elements by incrementally deforming metal sheets with a robotic tool. This research adapts the process for architecture, where mold-based methods are costly and inflexible. The goal is to build a digital workflow that connects design, material response, and robotic control. Main challenges include forming accuracy without formwork, managing deformation over varied curvatures, and aligning simulation with physical execution.

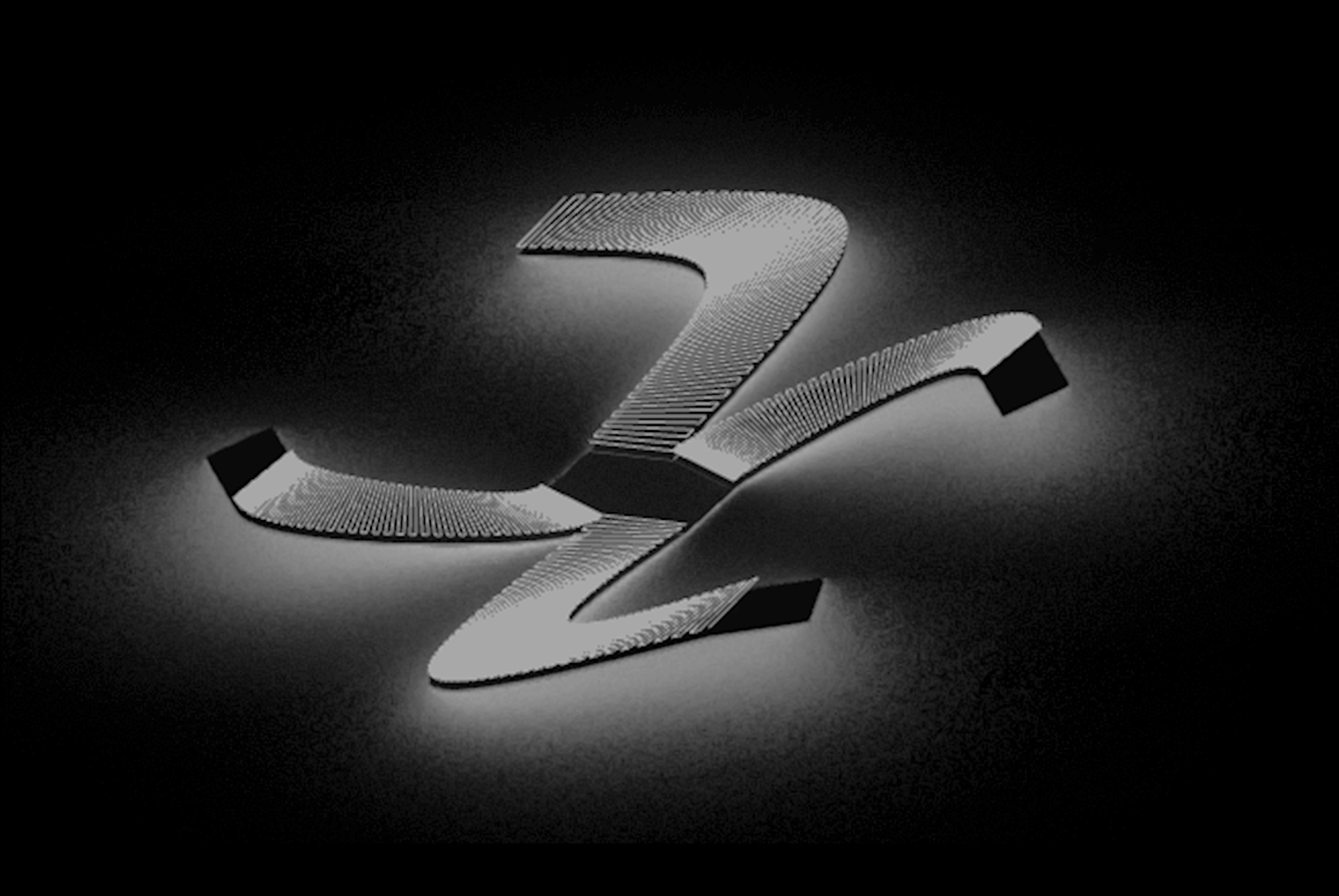

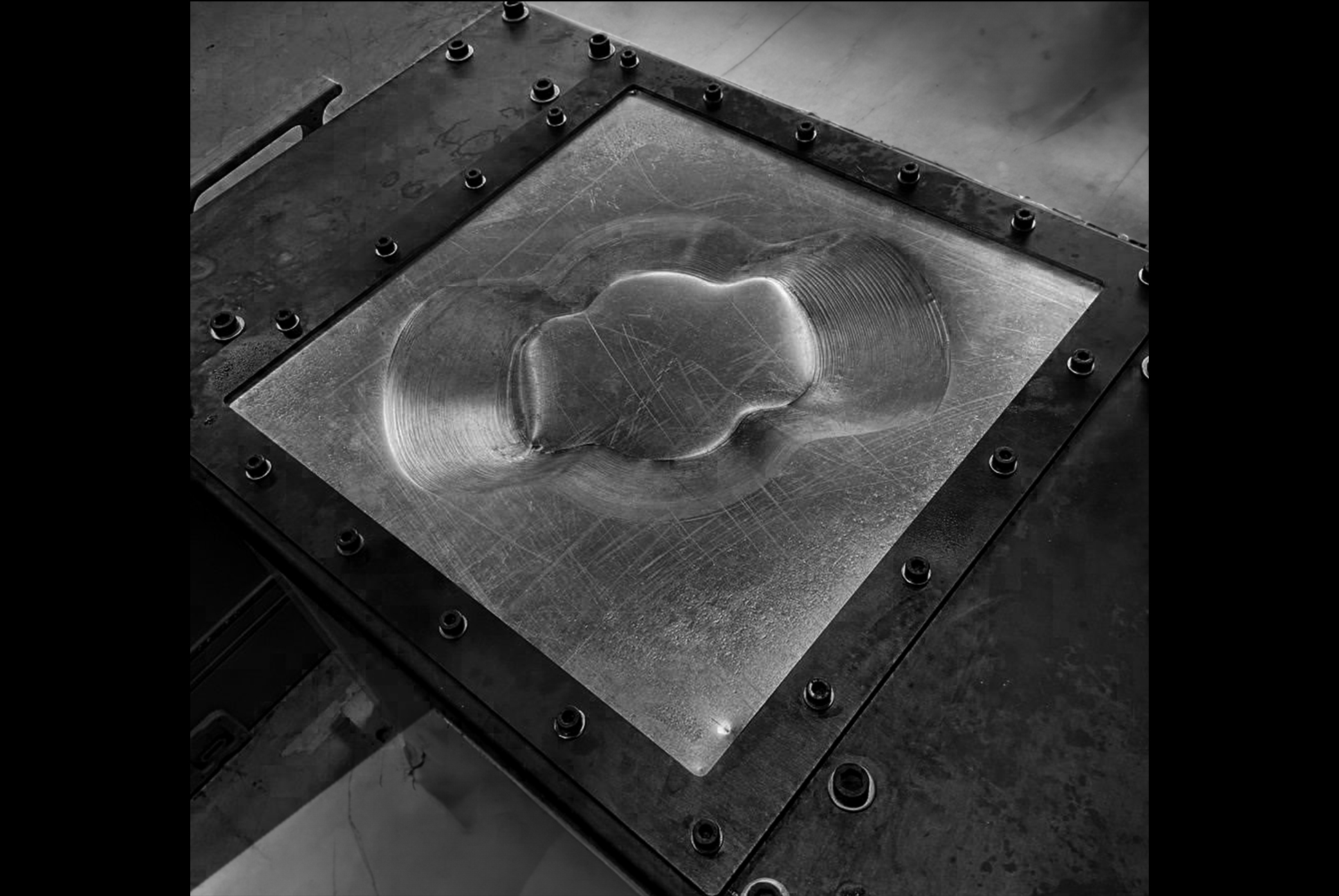

A 6-axis ABB IRB 4600-45/2.05 robot conducts SPIF tests on 500 mm by 500 mm aluminum and steel sheets in 0.6 mm, 0.8 mm, and 1.0 mm thicknesses. A custom steel end effector with a fixed 10 mm toolhead mounts directly to the robot flange. Sheets are clamped onto a welded steel frame using machined plates and bolts to ensure stability during forming. Toolpaths are generated in Grasshopper using custom scripts with the Robots plugin, combining spiral and tweening strategies based on surface curvature. Geometries are rationalized into planar segments with overlapping seams to reduce tool variation and support panel-to-panel continuity. Toolpaths are simulated in RobotStudio and calibrated through a four-point method aligning the digital model with the physical setup. A series of forming tests evaluate deformation behavior, toolpath performance, and forming consistency under different material and motion parameters.

The first test with 0.8 mm steel shows poor formability; the material is too stiff for SPIF, causing tool deflection and a collision. Tests with 0.8 mm and 1.0 mm aluminum show better deformation and process stability. Springback occurs in both, with 1.0 mm sheets retaining shape more predictably. The 10 mm toolhead performs consistently, and calibrated toolpaths closely follow the intended geometries.

space

MATERIALS

Aluminum | Steel

PROCESSES

Robotic Incremental Sheet Forming

DESIGNS

Tweening

space

ROLES

Indexlab promotes the R&D agenda on Incremental Sheet Forming, designing and building the tools and frameworks needed to explore the technology and identify scalable applications.

STAKEHOLDERS

LOCATION

INDEXLAB - Politecnico di Milano, Polo Territoriale di Lecco, Lecco, Italy

YEAR

2024

space