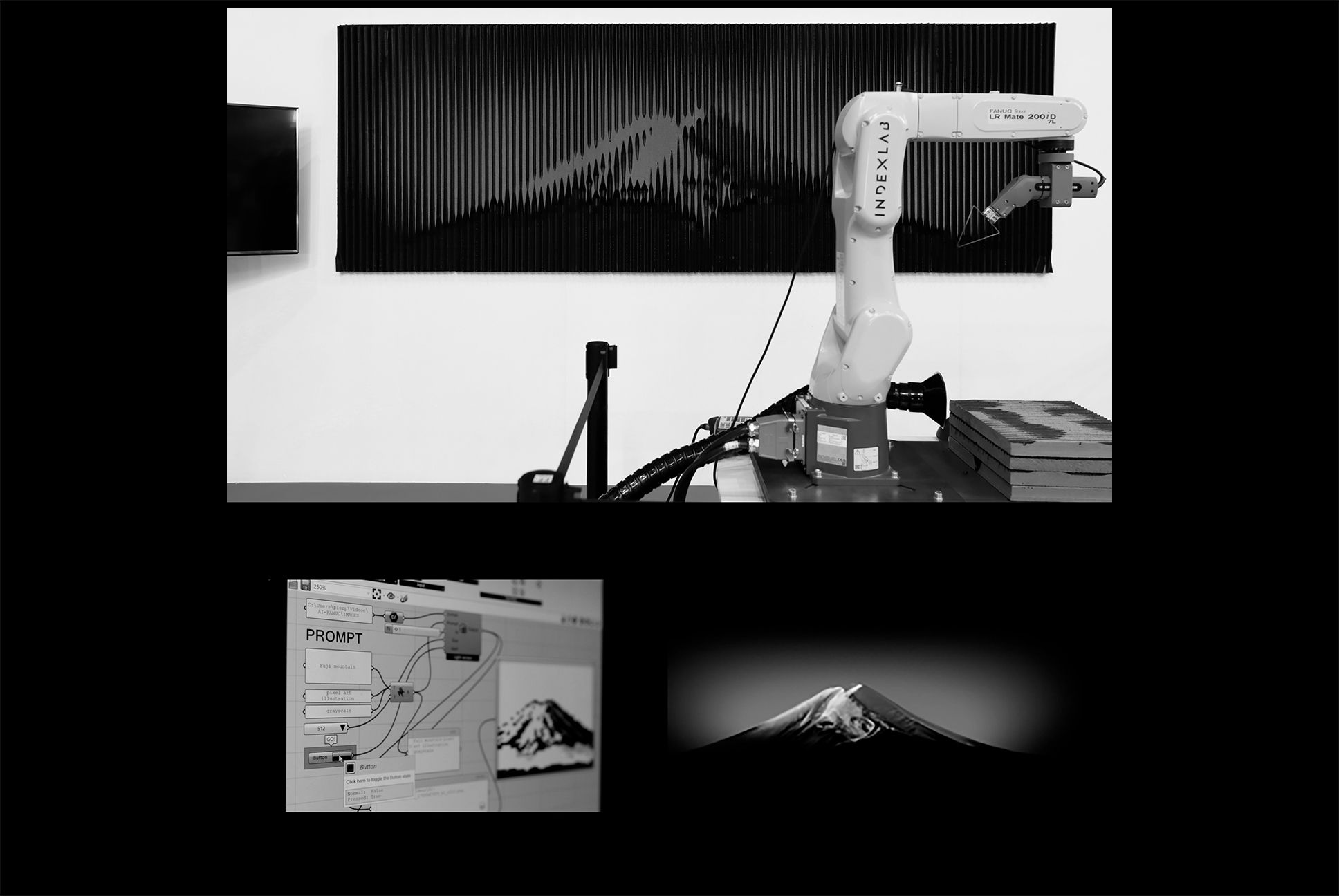

PROMPT2CARVE

automated toolpath generation and carving via generative AI

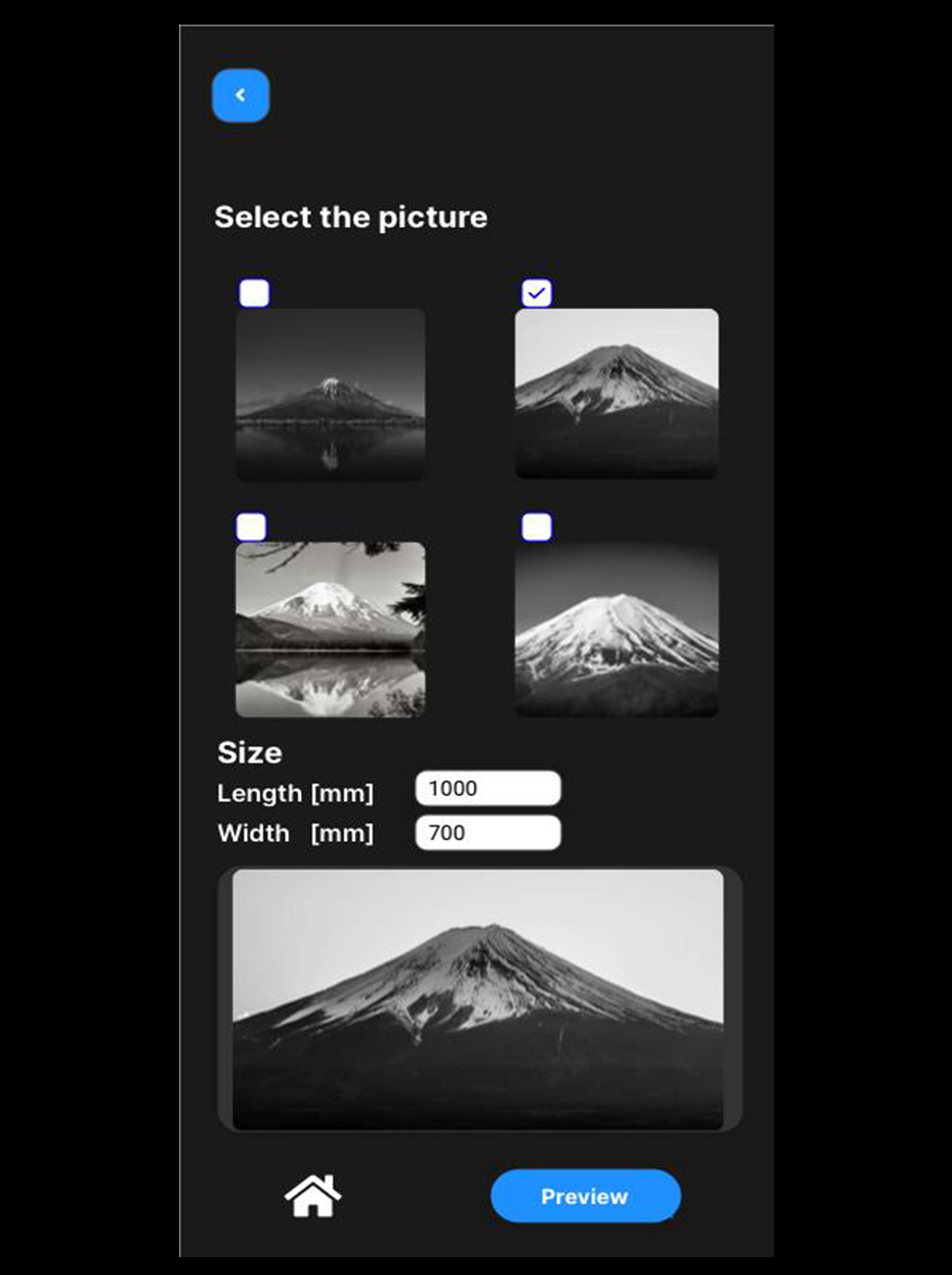

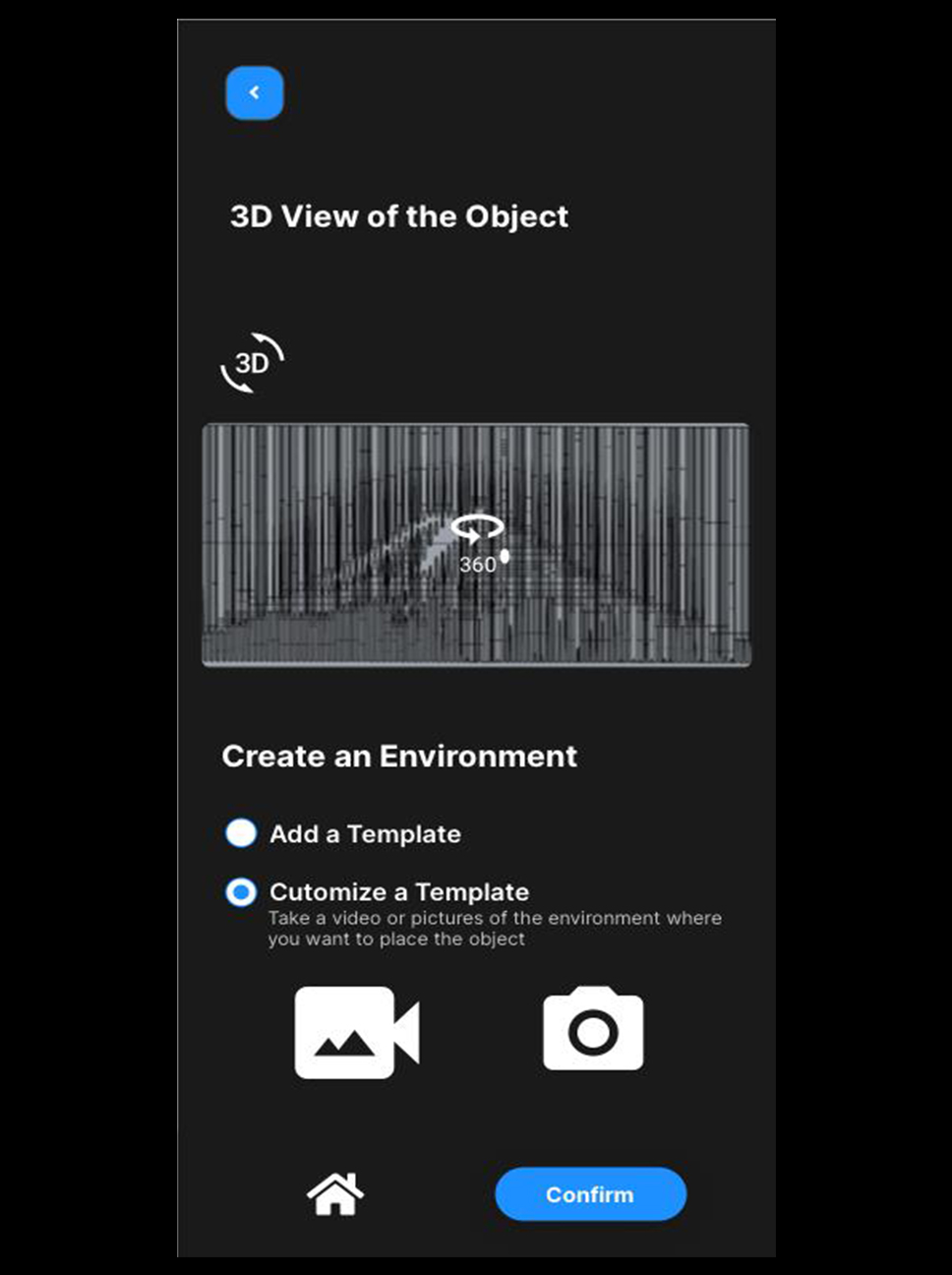

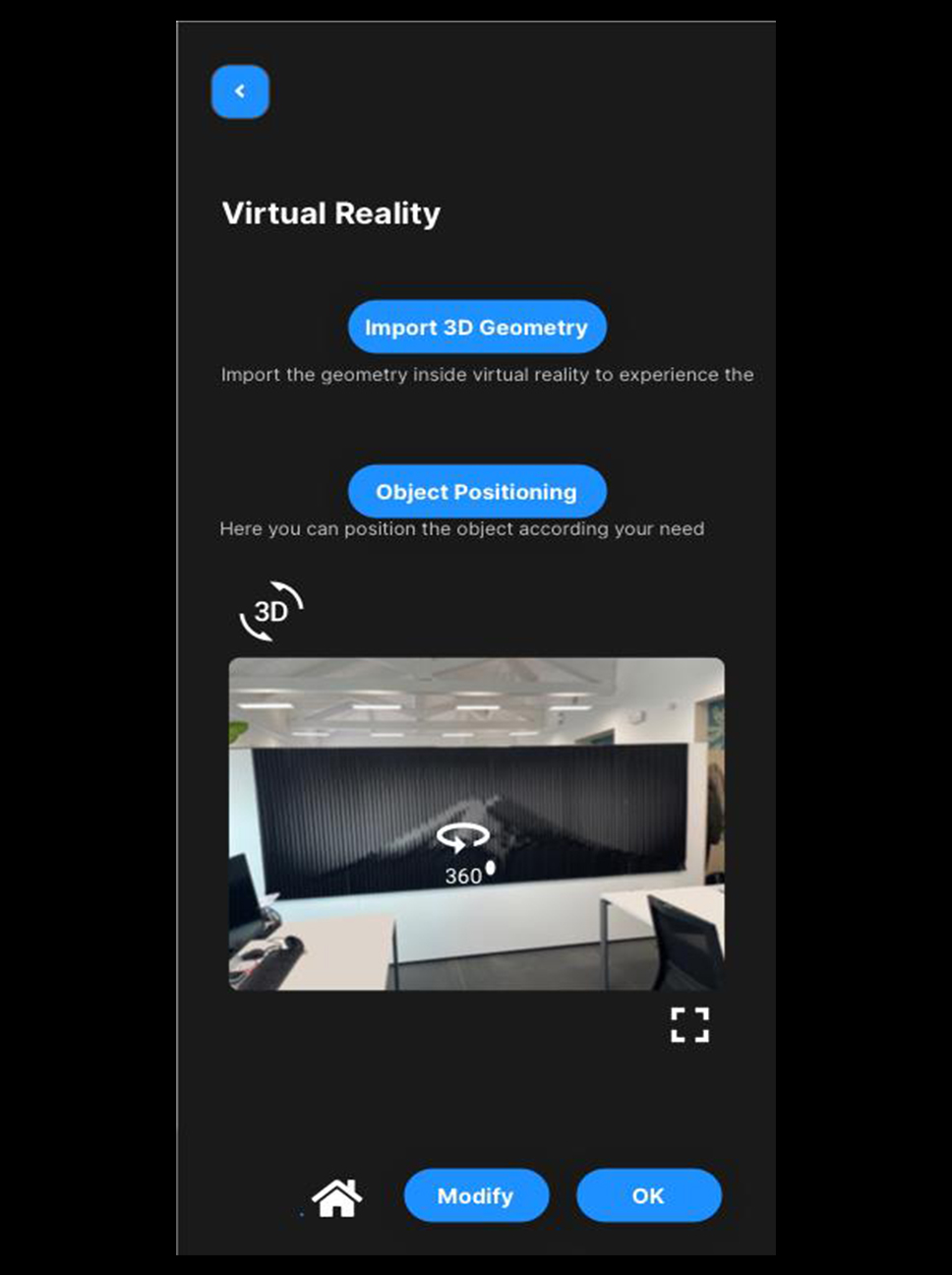

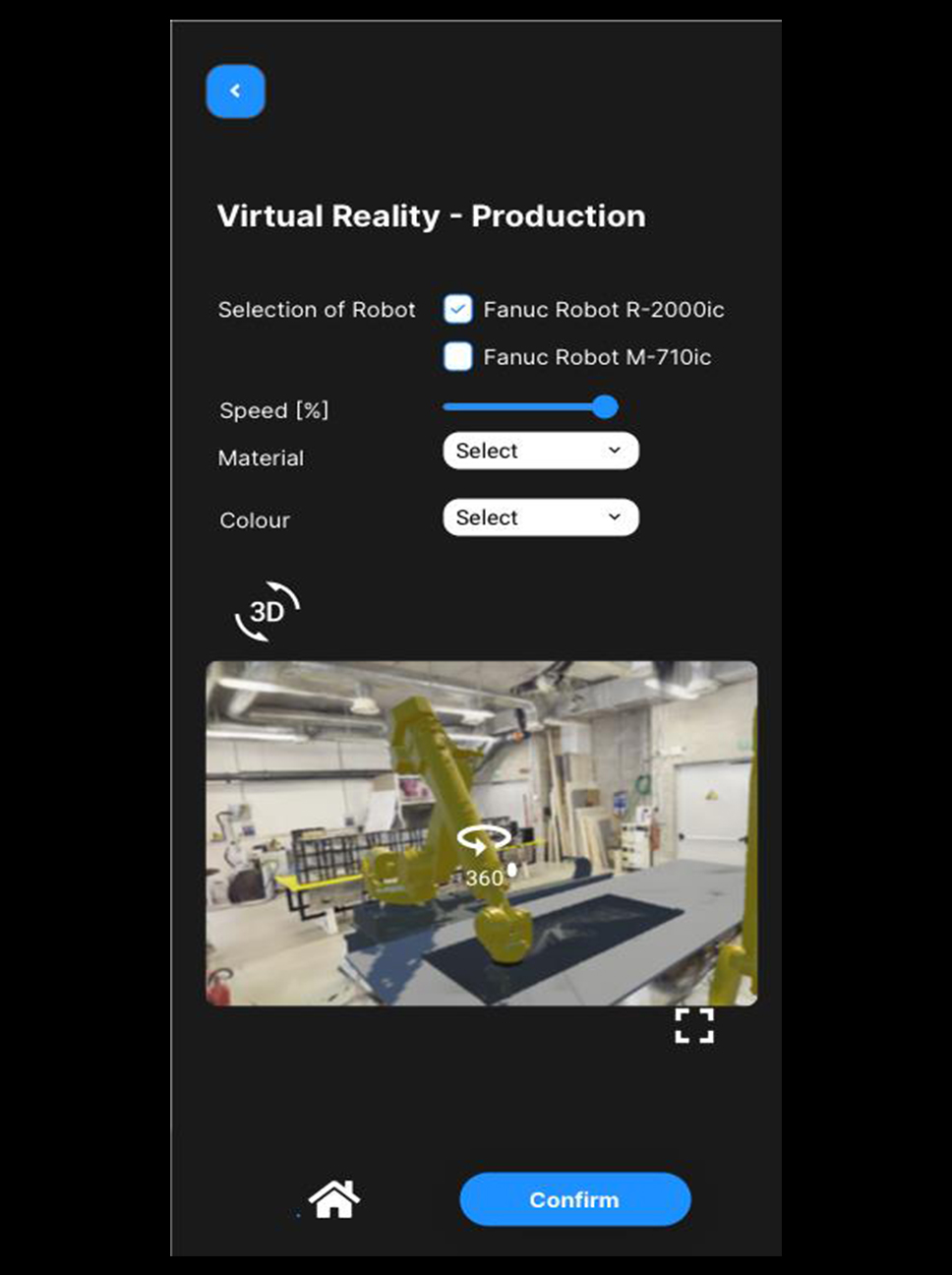

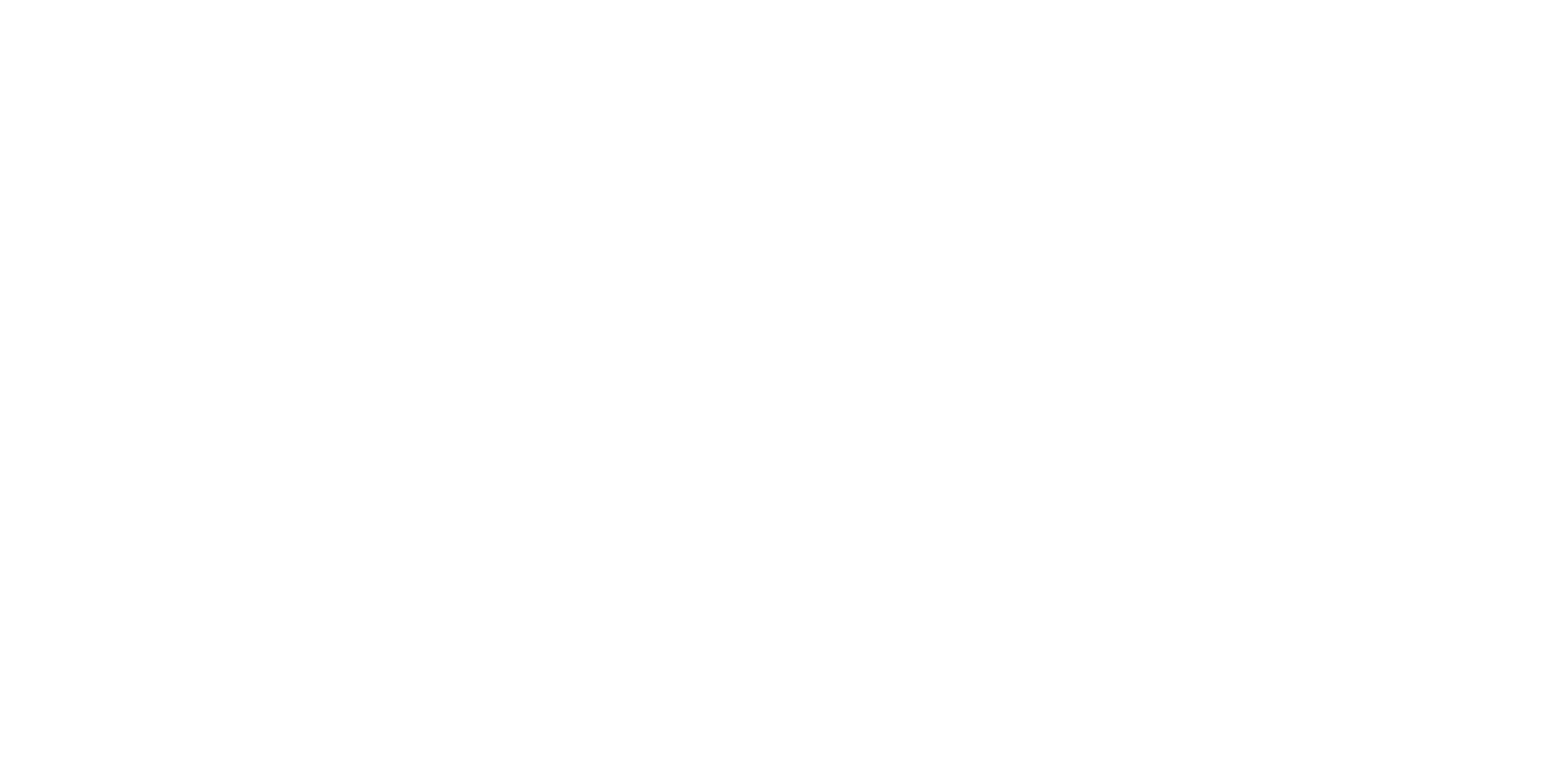

PROMPT2CARVE integrates generative artificial intelligence with robotic hot-tool carving to translate textual descriptions into bas relief panels. It overcomes traditional hand crafting bottlenecks by automating the entire pipeline - from prompt to finished relief. A prototype example successfully depicted Mount Fuji in extruded insulation foam. A companion app connects end users directly to on demand production systems, enabling custom acoustic panels or decorative elements. The process applies to multiple materials and carving methods, potentially transforming architectural panel production with flexible, just in time customization.

Recent advancements in text to image AI and CNC machining offer new avenues in digital fabrication. However, end to end automation that takes users from prompt to physical relief remains uncommon. PROMPT2CARVE seeks to fill this gap by combining AI image generation, automated toolpath creation, and robotic hot-tool execution. The goal is to enable users to produce personalized bas relief panels with minimal technical knowledge, within diverse material systems and production contexts.

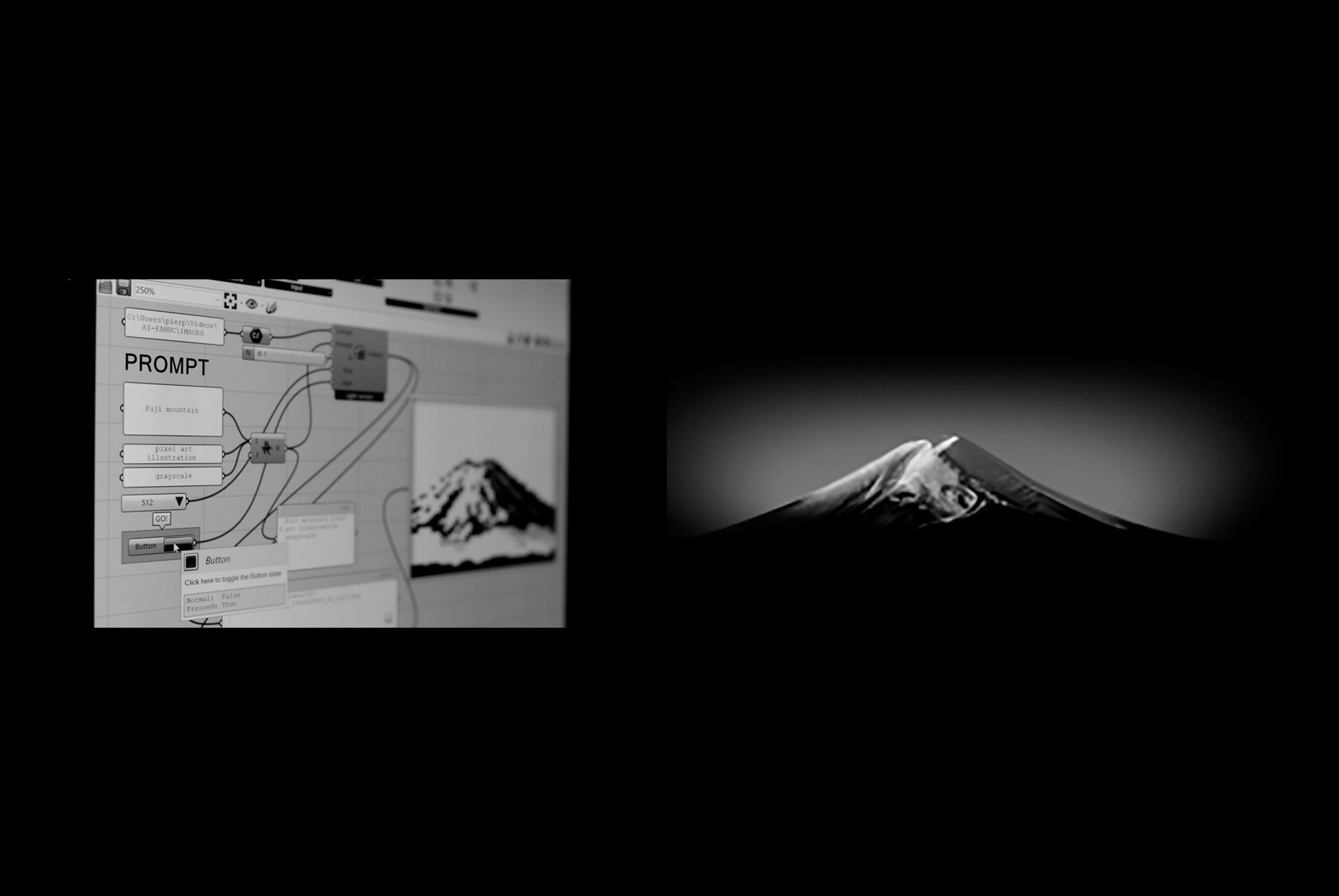

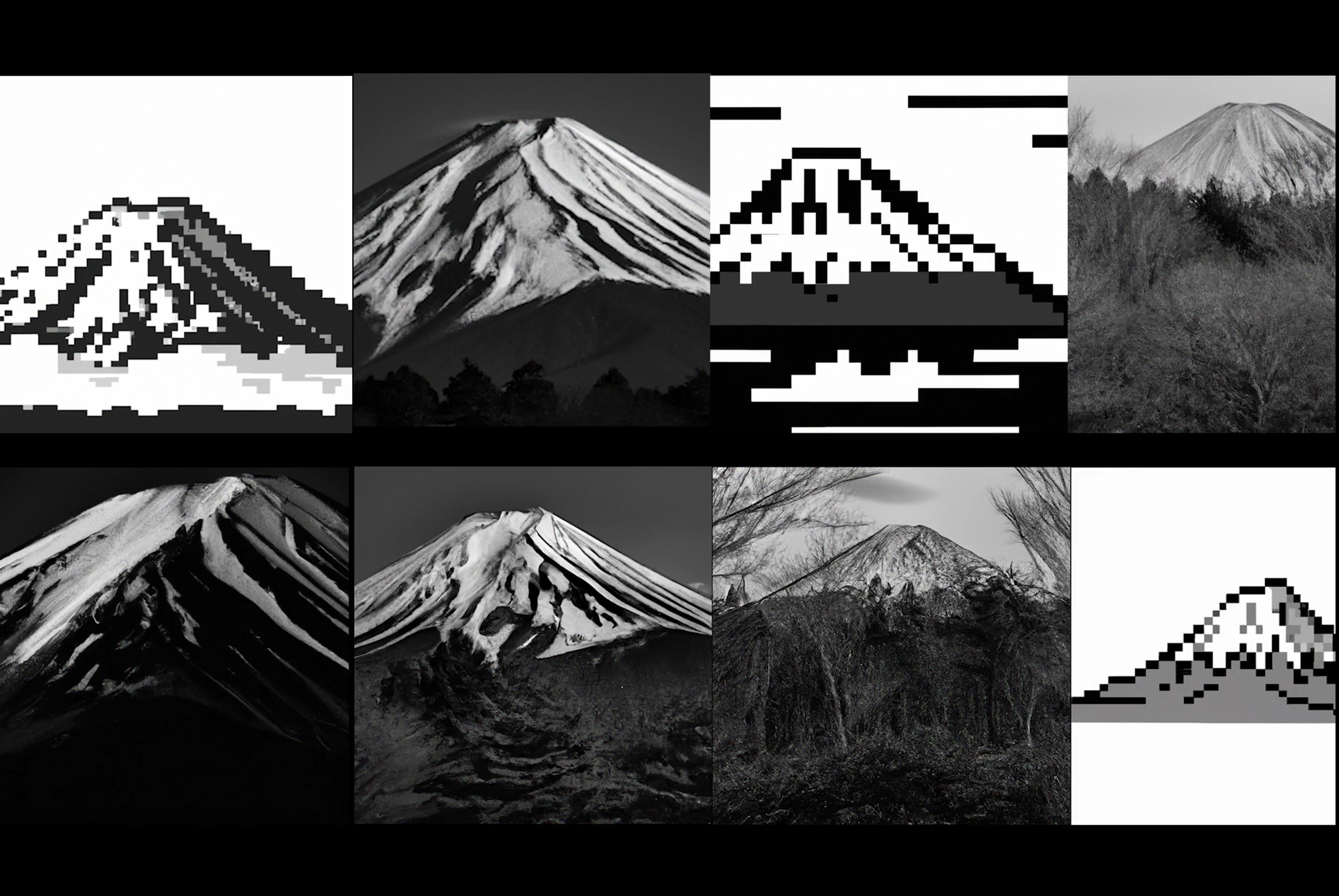

The system begins with a user-supplied textual prompt, processed by an AI model to instantly generate a 2D image. A conversion algorithm then translates the image into toolpaths.

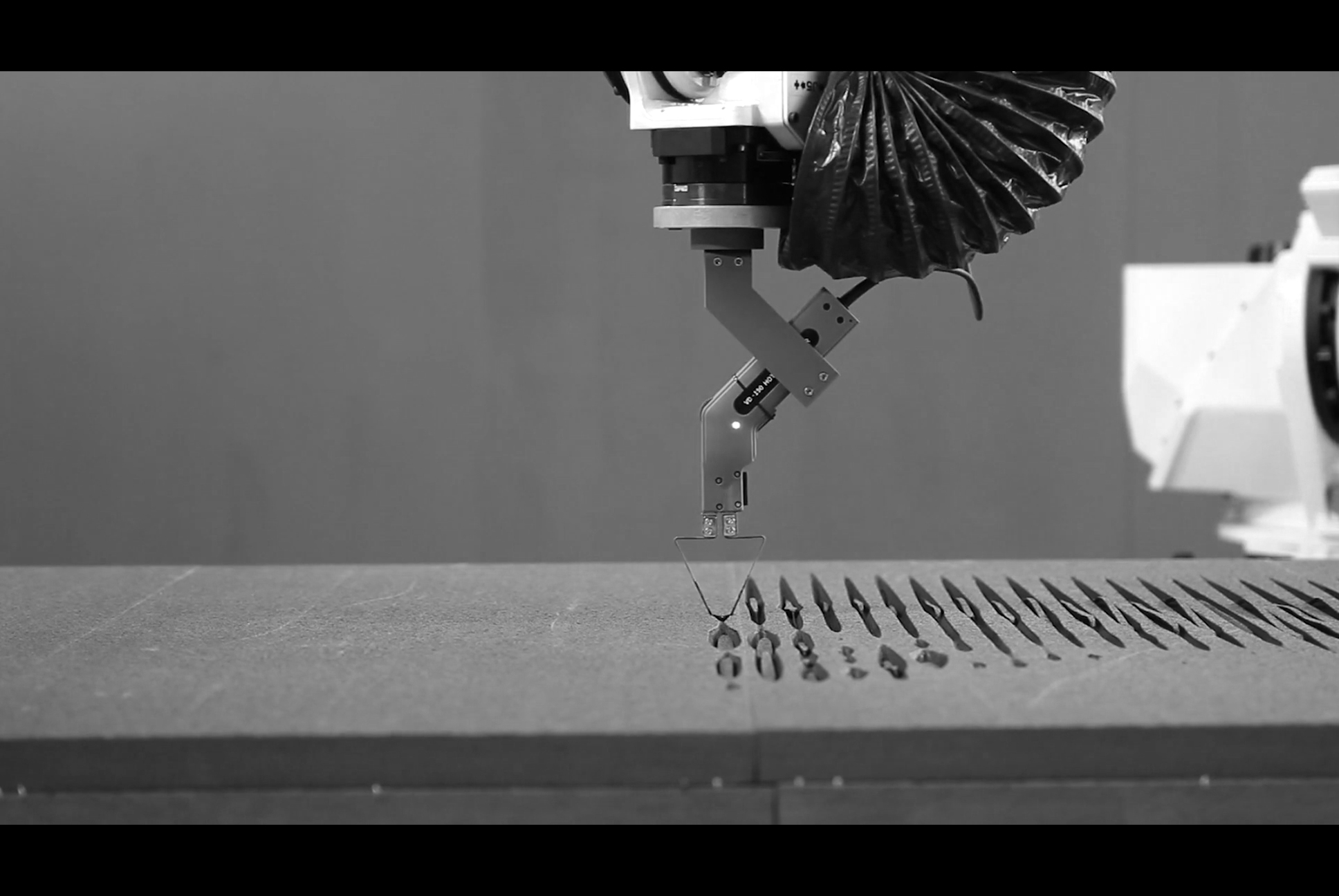

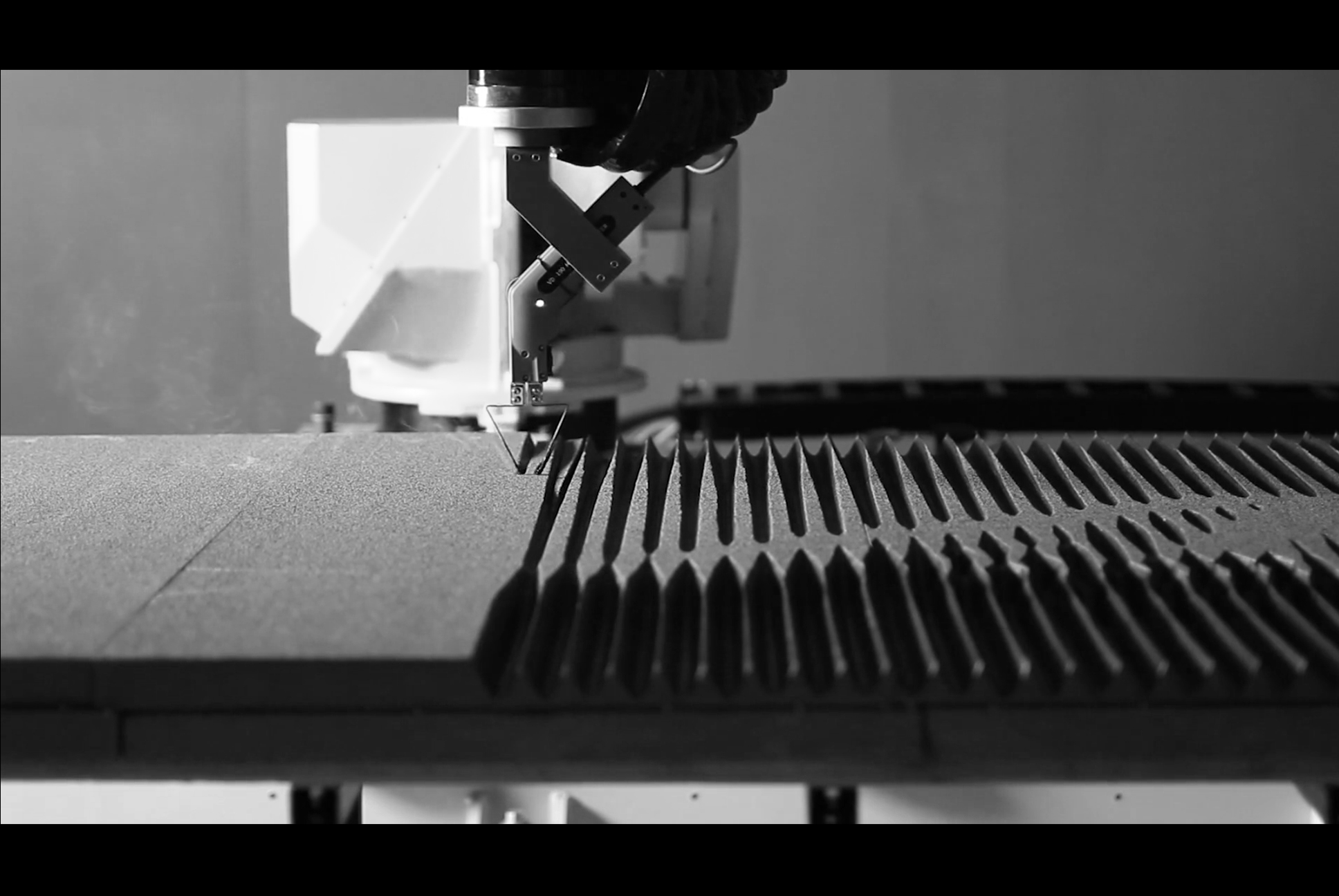

A robot-mounted hot blade executes the carving on XPS panels, following the calculated relief map. A mobile/web app interfaces with this pipeline, sending prompts, triggering carving tasks, and tracking production.

The modular architecture allows substitution of materials, machining heads, and fabrication environments to suit various applications.

A working prototype carved the silhouette of Mount Fuji in XPS using the automated sequence. The carved relief closely matched the generated image, demonstrating accurate shape reproduction and smooth toolpath execution. The integrated app interface successfully bridged end user input and robotic fabrication, establishing proof of concept for on demand, user-driven production.

space

MATERIALS

Extruded Polystyrene (XPS) | Digital Materials

PROCESSES

Robotic Hot Tool Cutting | Artificial Intelligence & Machine Learning

DESIGNS

Using a Moving Frame Along a Curve | AI Image Generation

space

ROLES

Indexlab developed the concept, defined the method, and prototyped multiple mock-ups at various scales. The team adapted tools and processes to enable end-to-end automation, from user input to finished product. PROMPT2CARVE paves the way for customizable, on-demand architectural elements across various materials and applications.

STAKEHOLDERS

LOCATION

INDEXLAB - Politecnico di Milano, Polo Territoriale di Lecco, Lecco, Italy

YEAR

2024

space