DISCRONIX

Filament-based screw-extrusion system for fabricating interlocking thermoplastic modules through discrete geometric logic

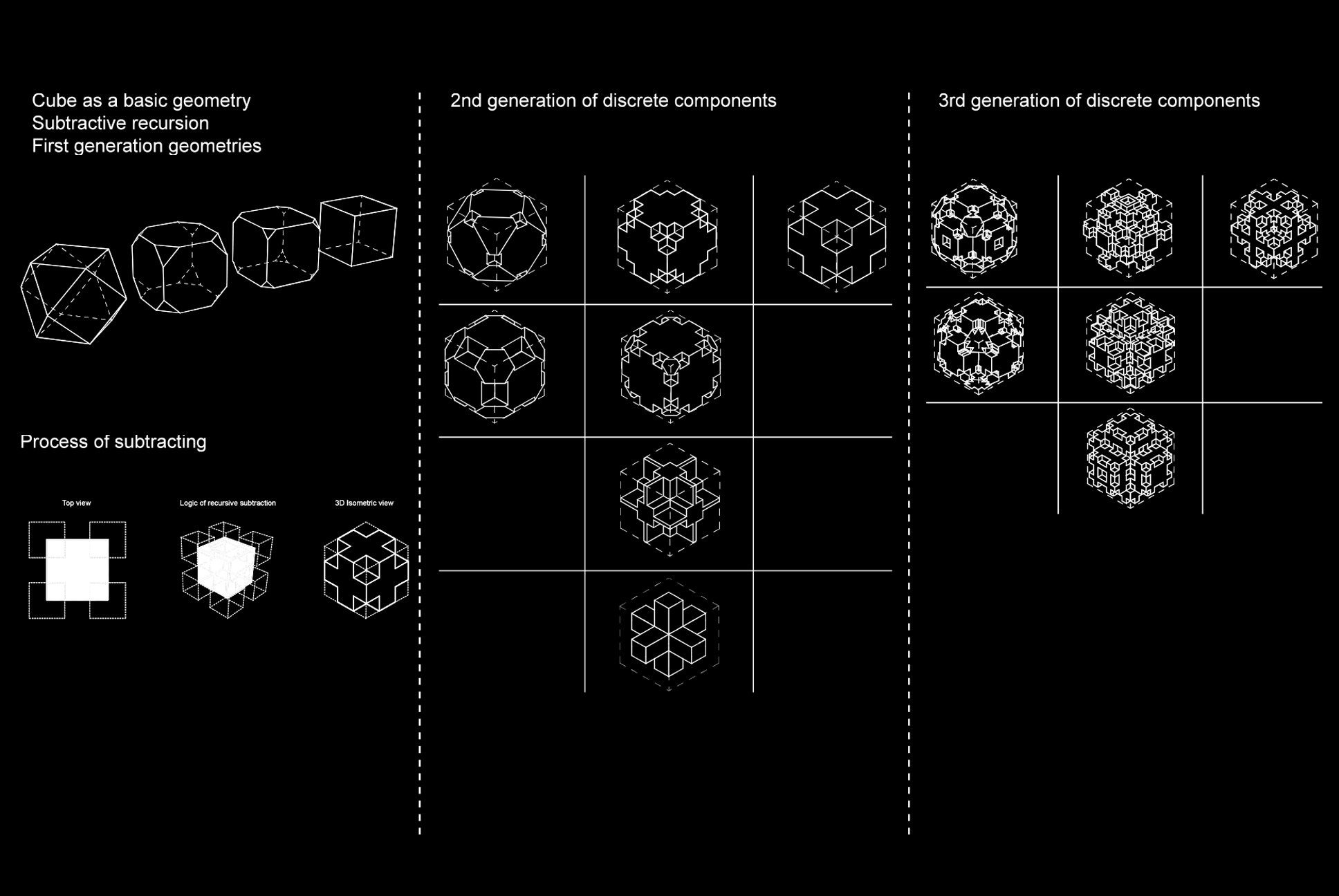

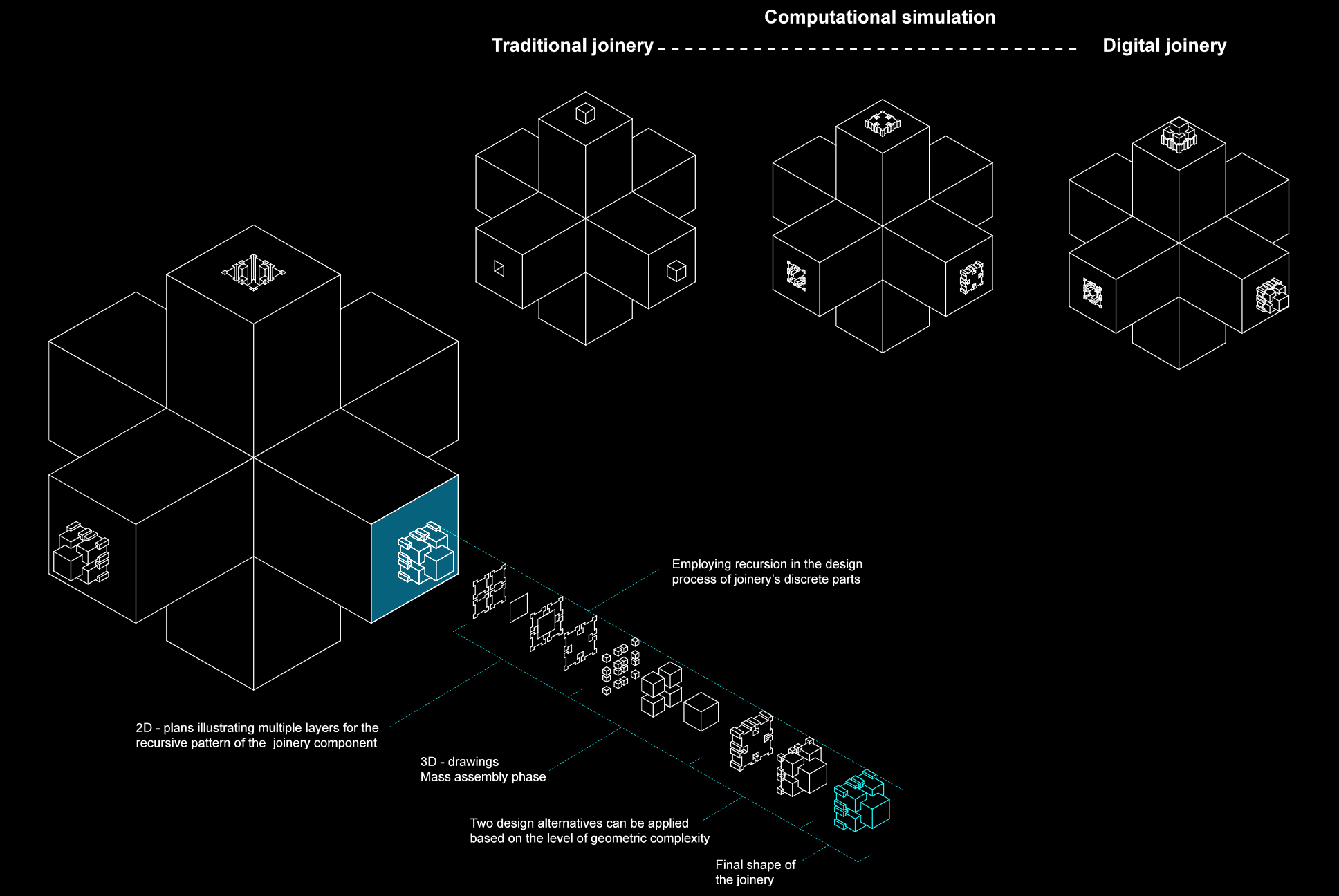

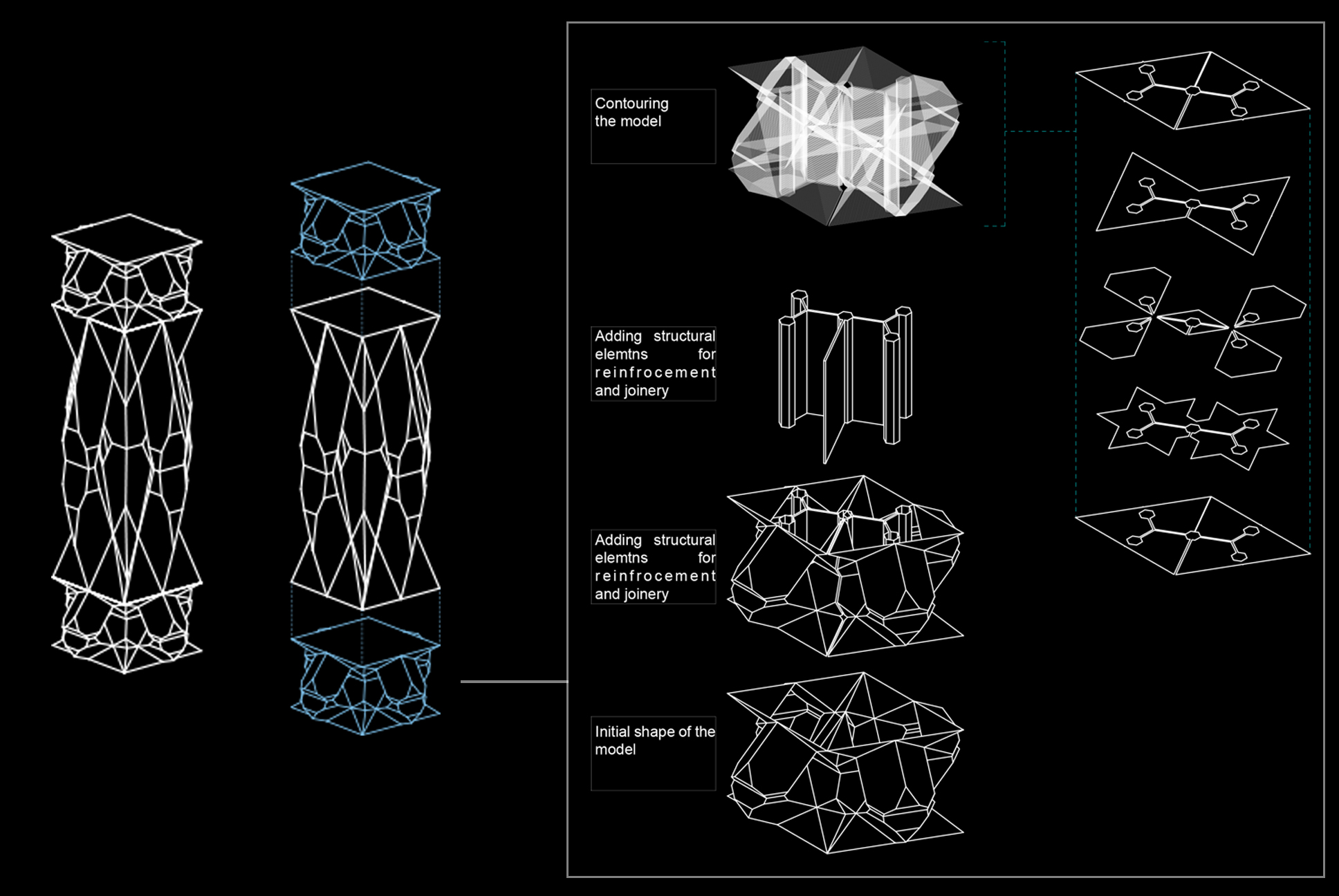

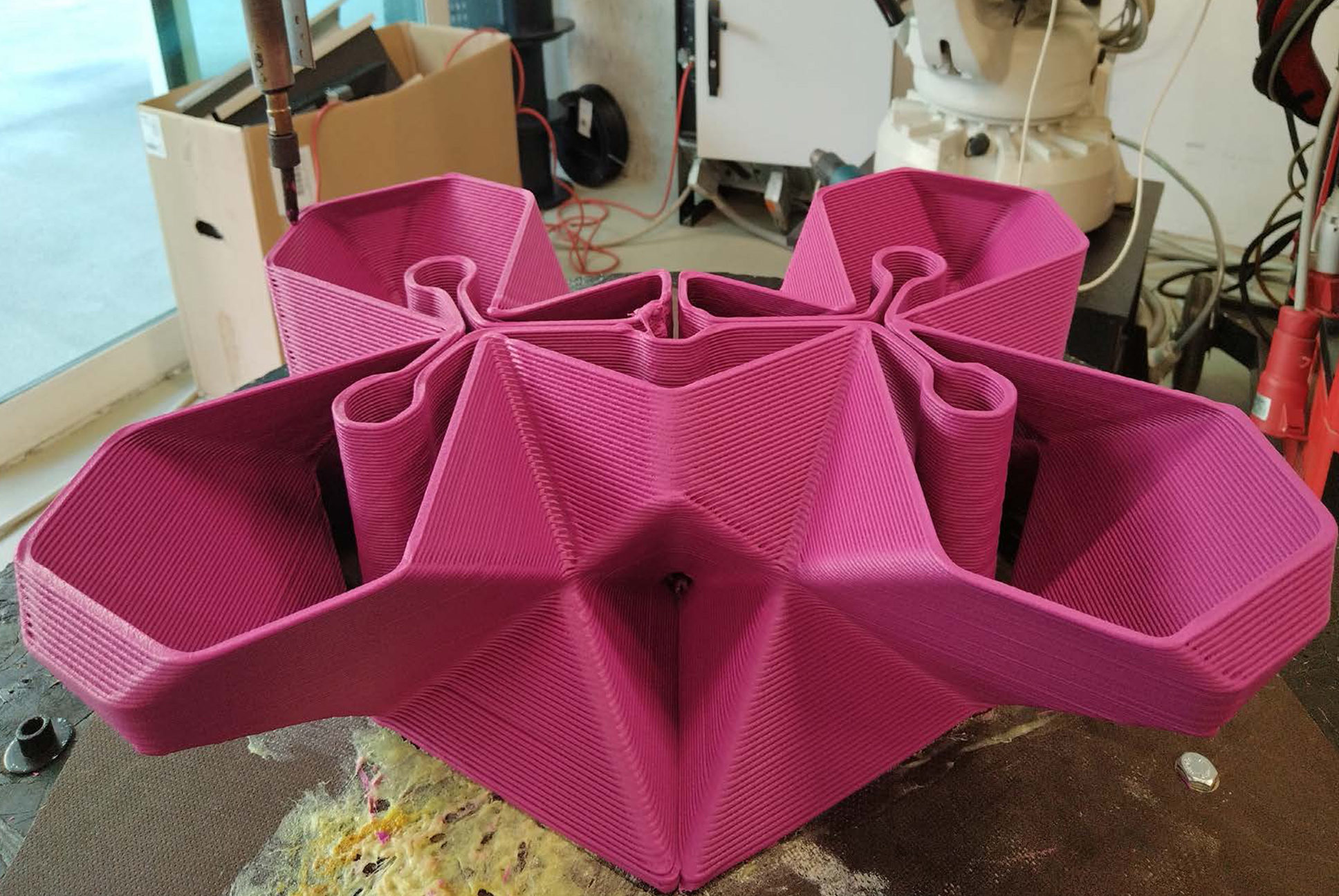

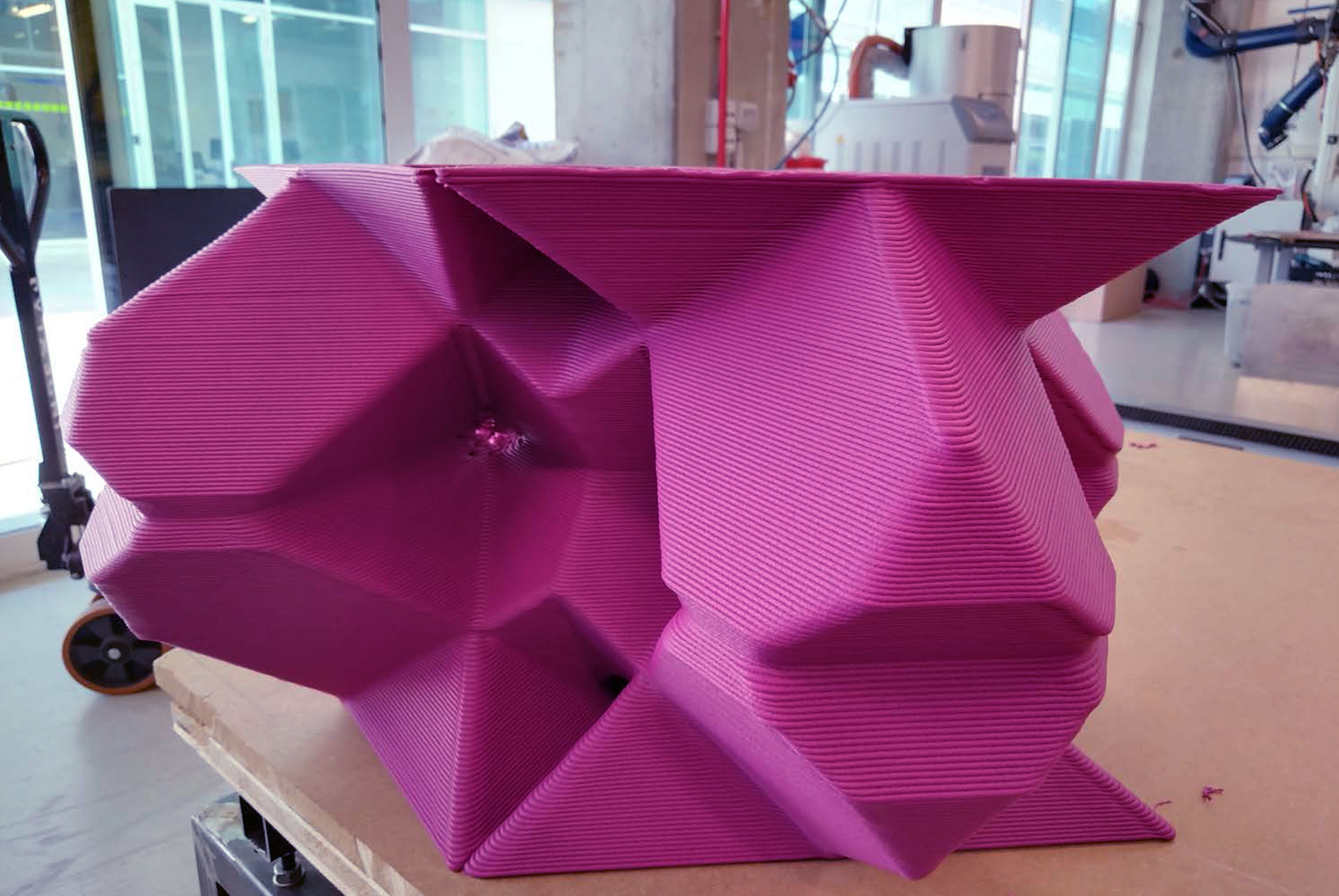

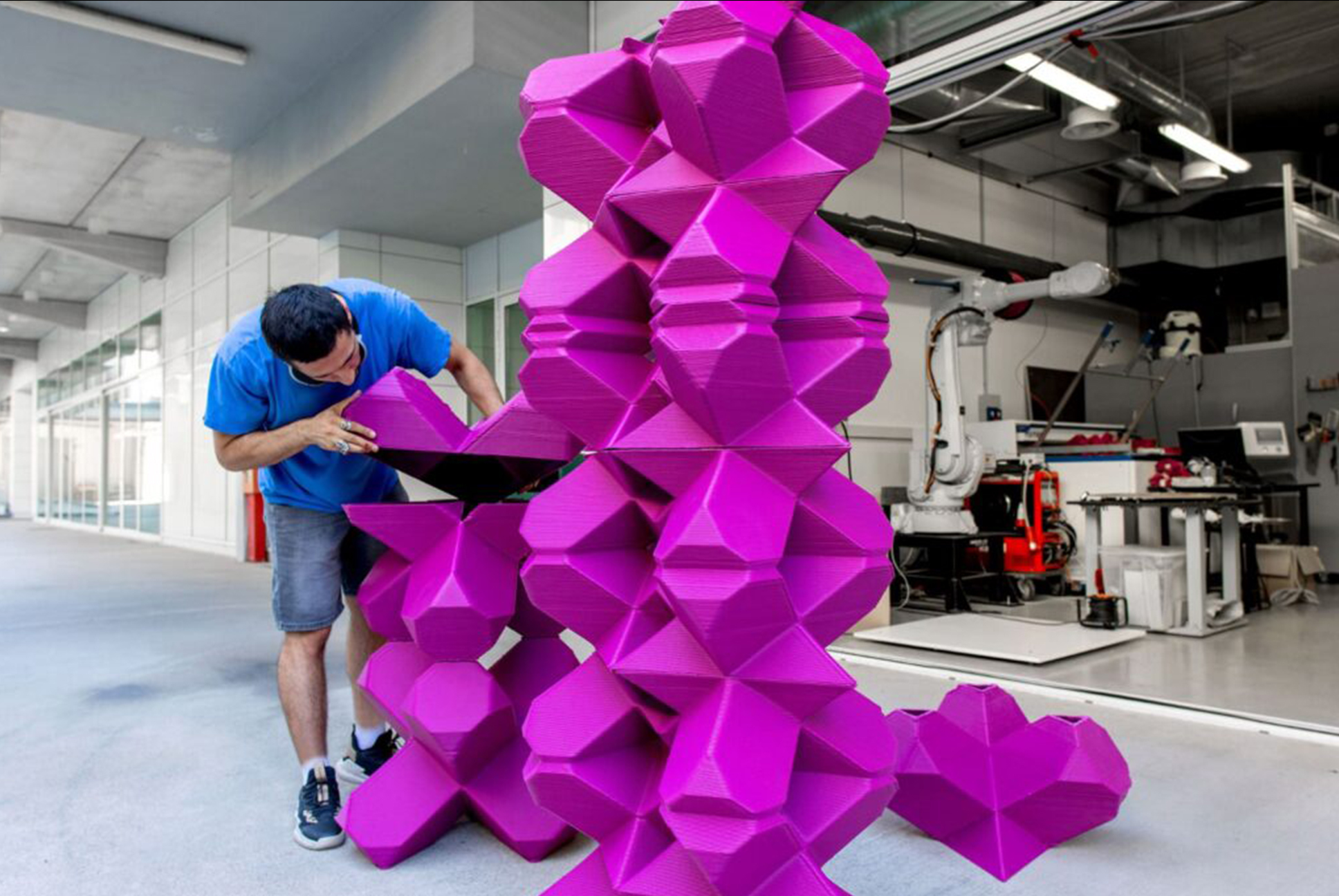

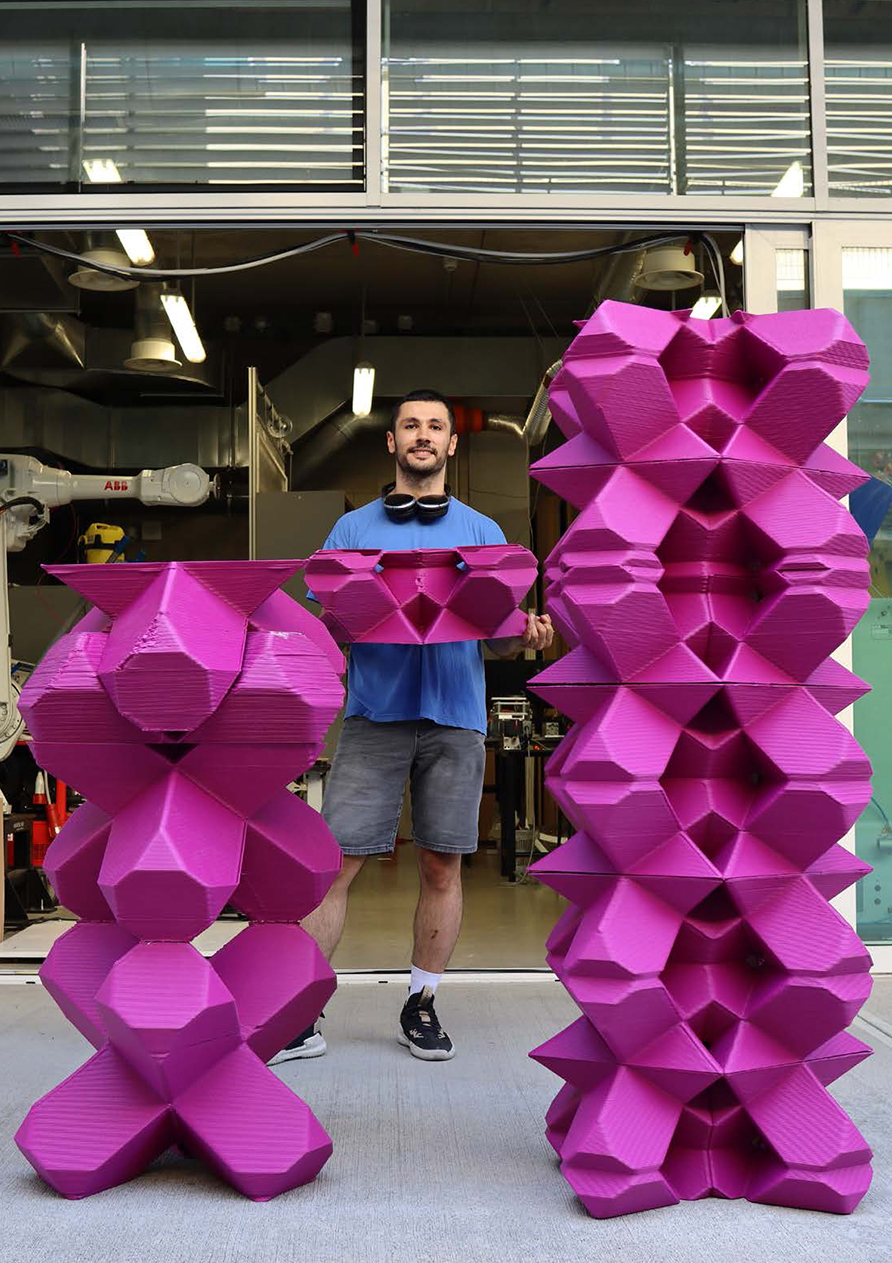

DISCRONIX investigates a system for producing structural ornaments through robotic extrusion and modular design logic. The project focuses on discrete geometry and a custom filament-based screw extrusion process to fabricate interlocking thermoplastic elements at architectural scale. It moves away from decorative surface treatments and generates ornaments through the geometry, assembly logic, and constraints of the fabrication process.

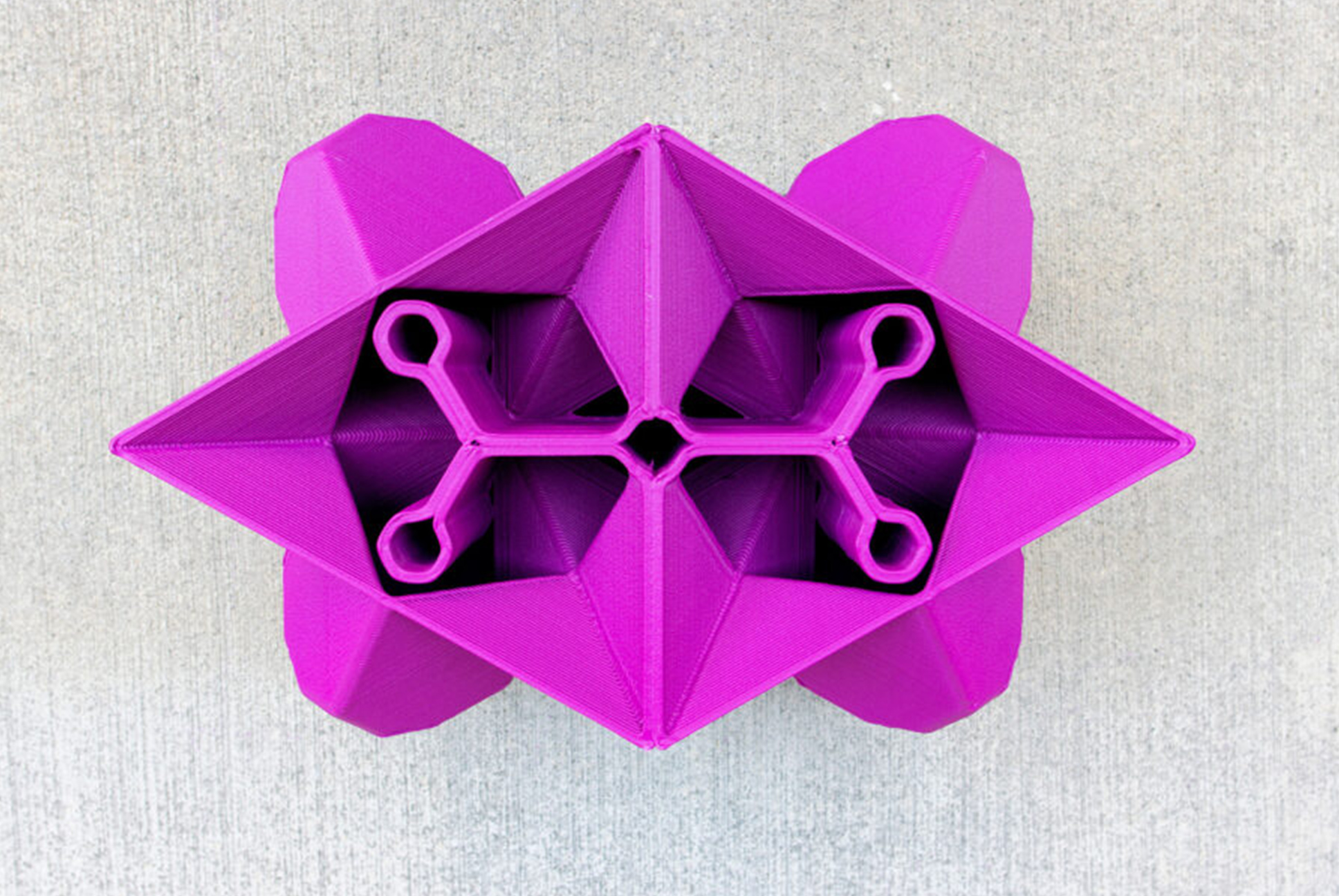

DISCRONIX redefines architectural ornament as a system of structural, interlocking components fabricated through robotic extrusion. It focuses on producing large-scale thermoplastic self-supporting parts, using discrete geometry, material-specific joinery, and a custom filament-based screw extrusion process.

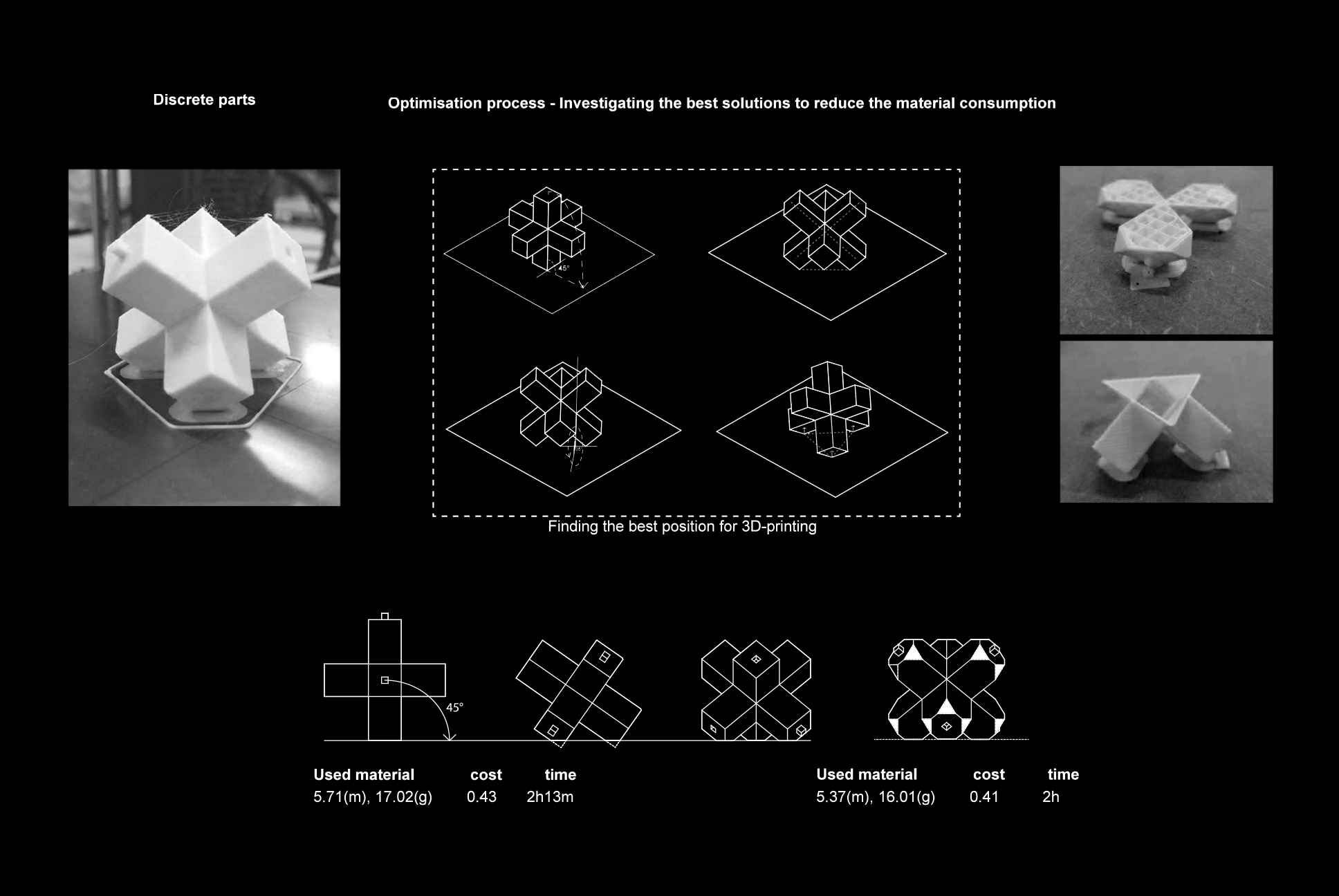

Key challenges include breaking continuous geometry into printable modules, designing joints for fast assembly, and aligning fabrication parameters such as seam placement, toolpath, temperature, and speed with both form and structural performance.

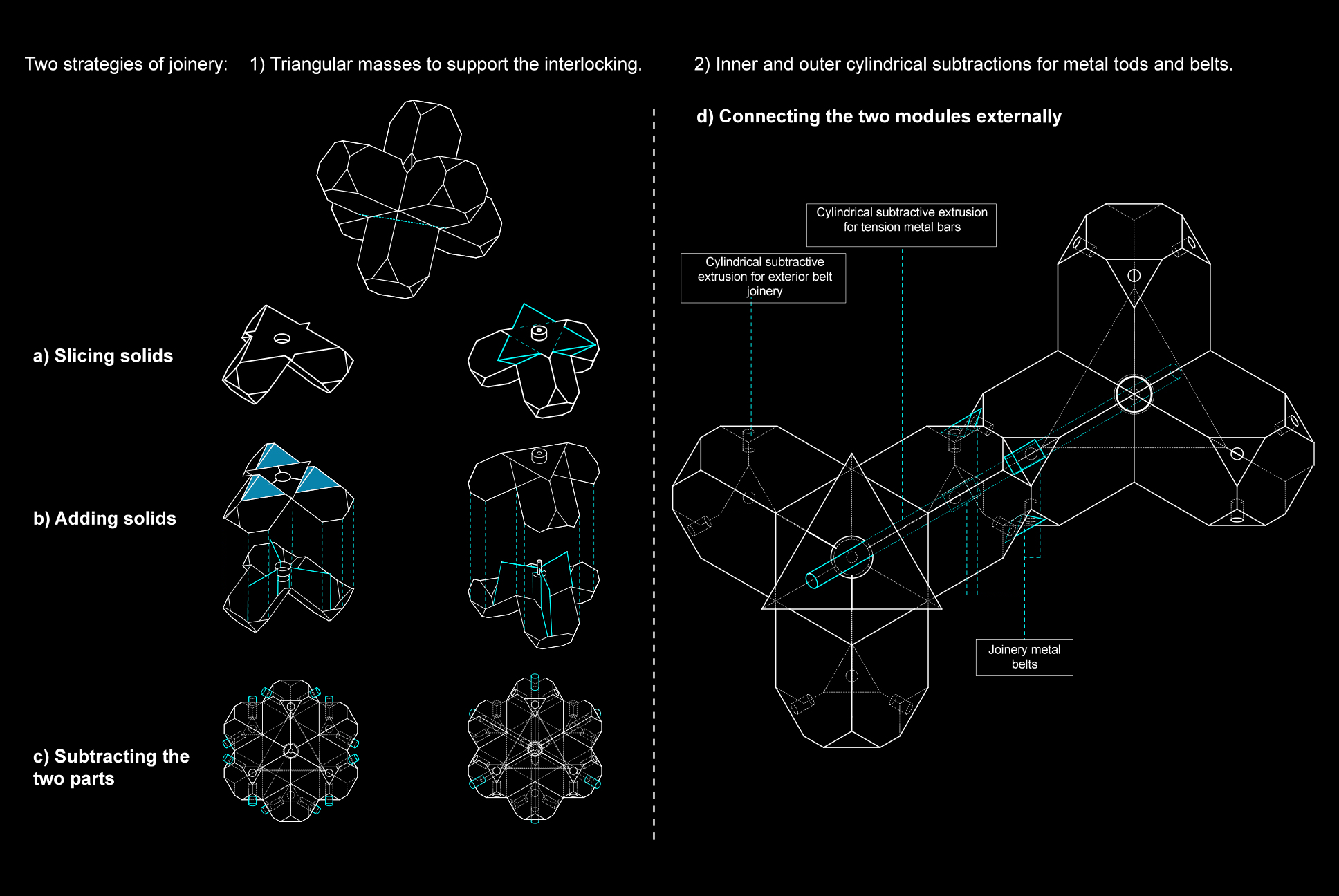

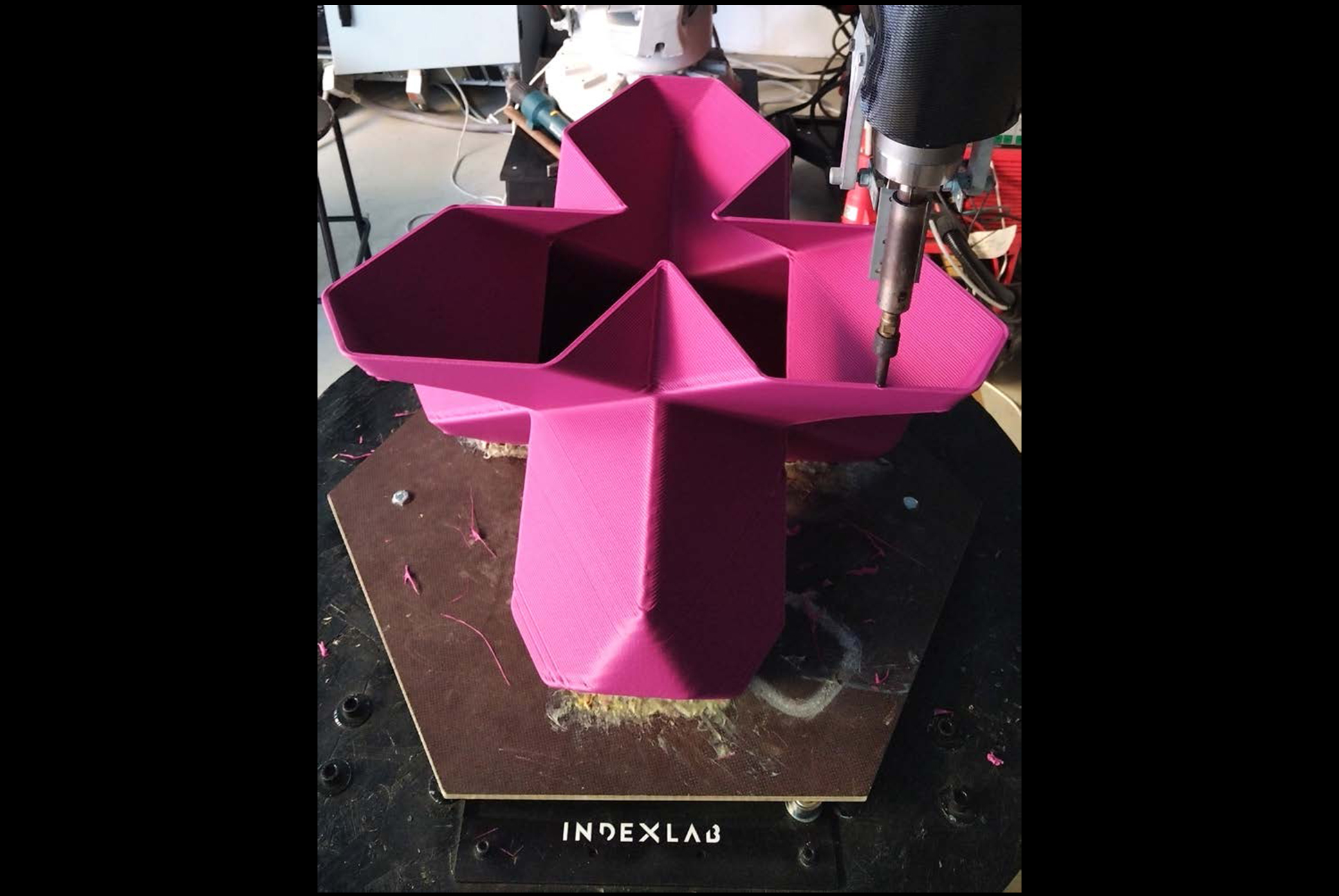

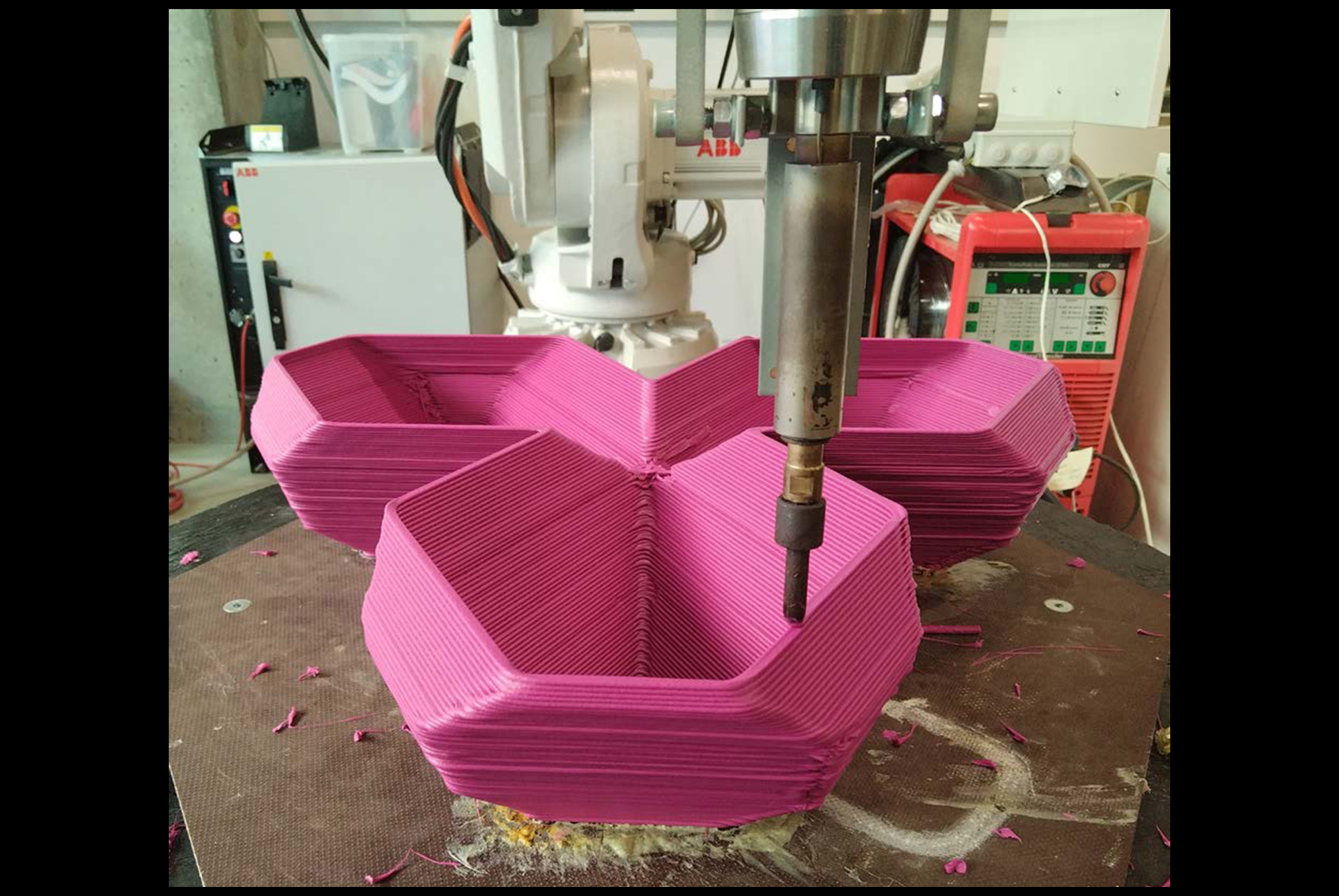

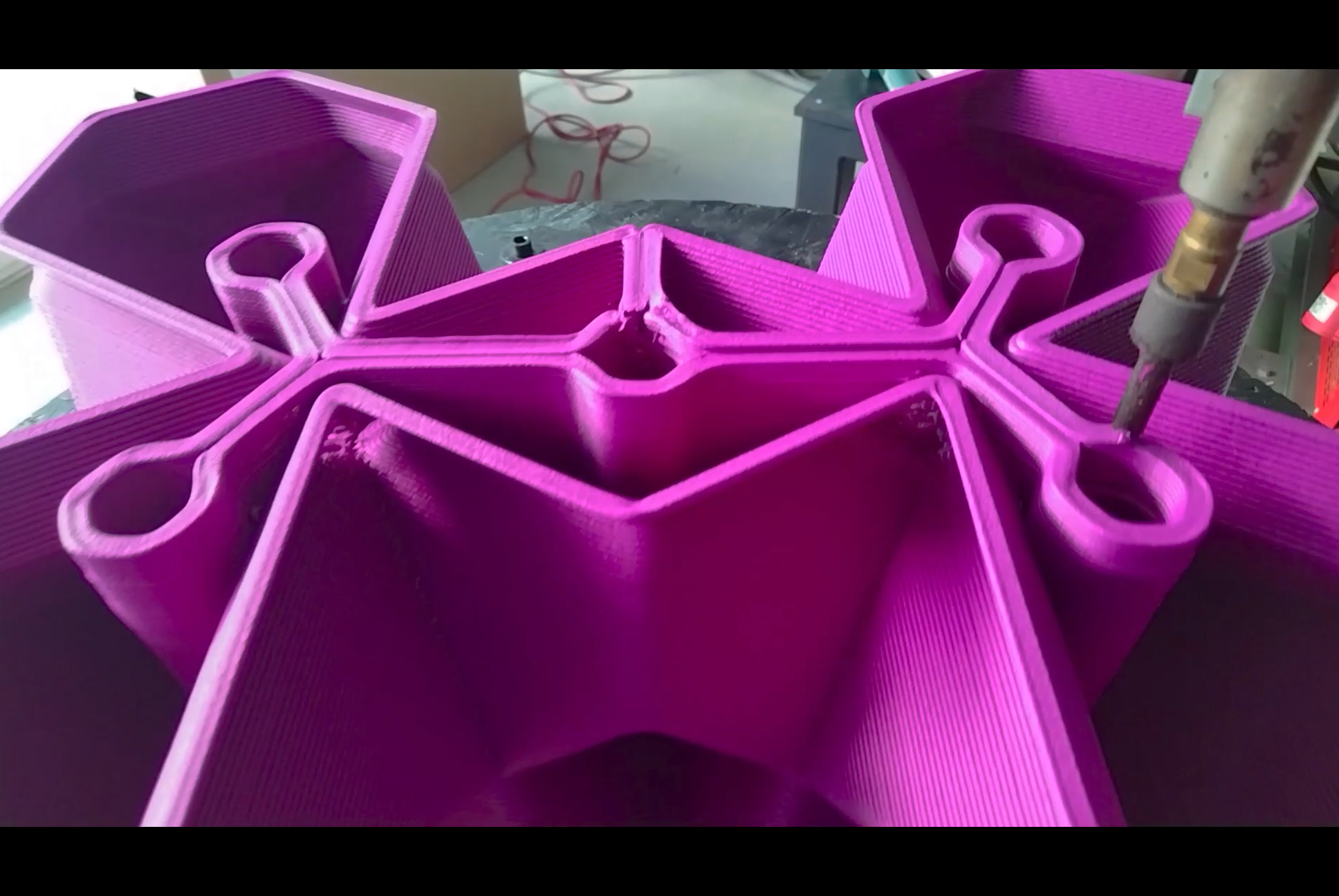

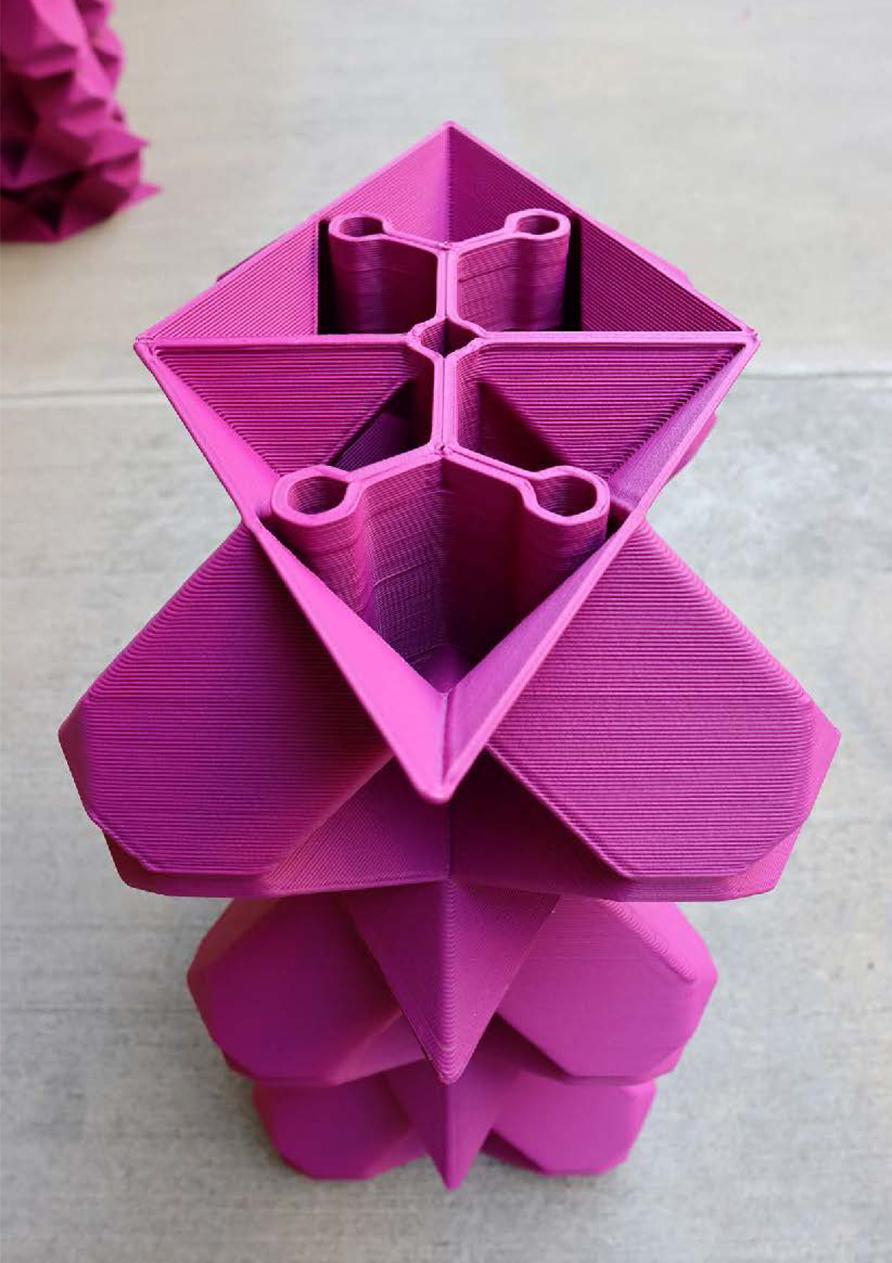

The process begins with patterned geometric subtraction, generating discrete components shaped for interlocking joinery using tongue-and-groove or nested seams. Glass fiber-reinforced polypropylene is fed, chopped, and melted within the Leister WELDPLAST 600, a welding machine repurposed as an extruder, enabling continuous, high-flow deposition at architectural scale. Each module’s geometry defines its toolpath, seam layout, and extrusion parameters, ensuring joint bonding and clean edges.

Support structures are avoided by limiting surface angles to a maximum of 45°, material stiffness, and directional printing.

Joints are further designed with integrated holes for post-tensioning, allowing later insertion of reinforcing steel cables or tensioning systems. This ensures that structural reinforcement can be added after fabrication. Following assembly, the structure can be enhanced through concrete casting, increasing overall stability and load-bearing performance.

Prototyping focused on orientation, seam control, and assembly fit, with refinements in joint design, path scripting, and robotic motion. Simulations were used to anticipate collisions and extrusion errors.

Printing and assembly tests confirmed the effectiveness of the joinery logic and the alignment between digital model and physical output.

space

MATERIALS

Steel | Concrete | Polypropylene

PROCESSES

DESIGNS

Filament-Based Screw Extrusion | Casting | Groove Joint | Robotic 3D-Printing

Slicing | Discrete Part-Based Modularity

space

ROLES

.

STAKEHOLDERS

LOCATION

.

YEAR

2022

space