AMARCORD

Capturing the motion of dance in a flowing, data-driven physical installation

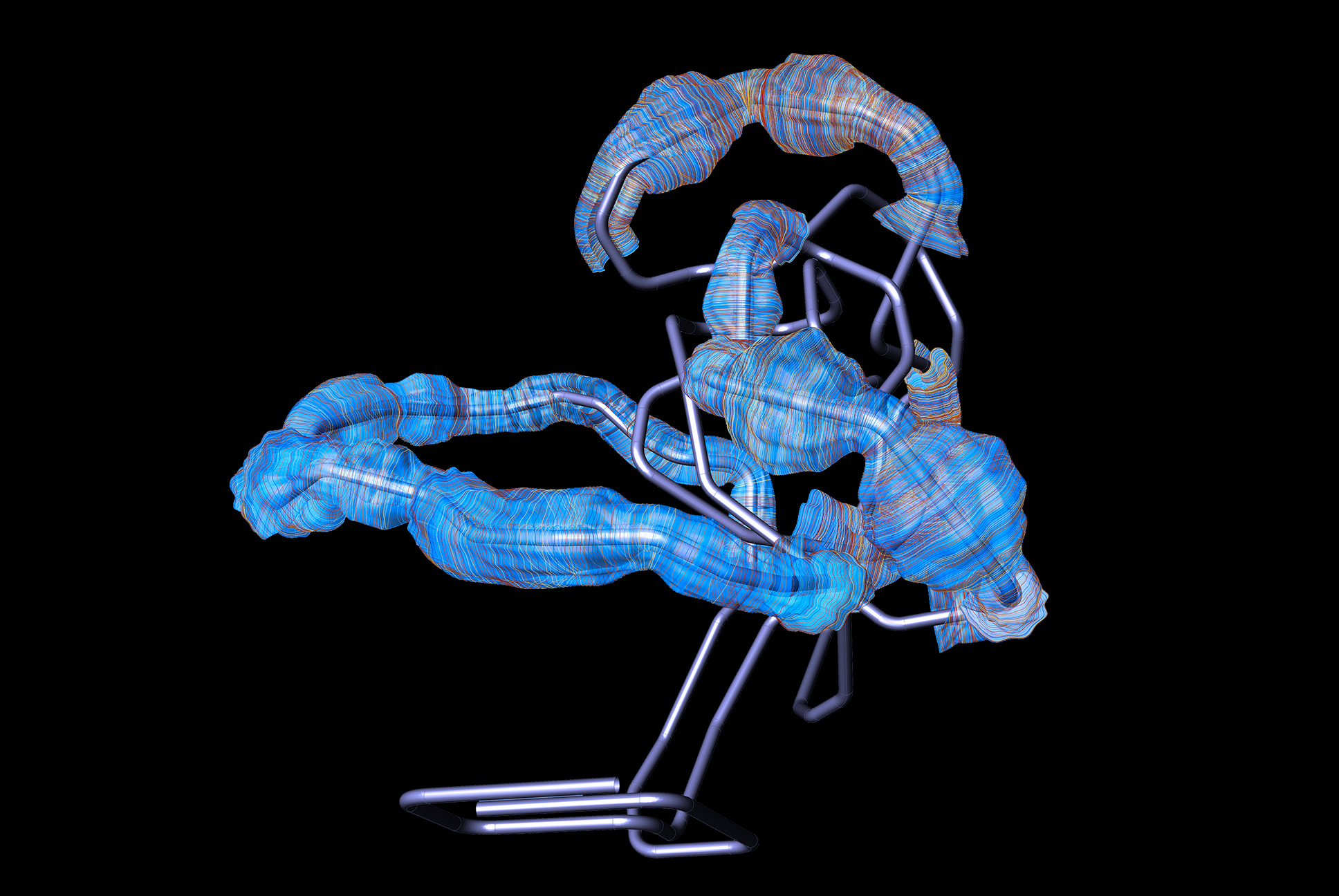

AMARCORD bridges the worlds of art and technology, transforming the fleeting essence of dance into a tangible, abstract installation. By tracing a dancer’s movements, parametric modeling generates a tubular structure where each element reflects temporal and kinetic variations. Advanced 3D printing produces polycarbonate modules with dynamic cross-sections, while a CNC tube-bending machine shapes unique curves, guided by a custom algorithm developed by Indexlab. Augmented reality integrates the assembly process, aligning a digital twin with physical components to ensure seamless construction. The result is an artwork that redefines motion in material form, demonstrating the potential of computational design and digital tools in creative representation.

AMARCORD reinterprets the transient beauty of dance into a material and technological form. The project aims to convey immediacy and movement through a sculptural installation, combining cutting-edge fabrication techniques and algorithmic design. By translating the motion of a dancer into a tubular structure, the work explores the interplay between the ephemerality of performance and the permanence of material.

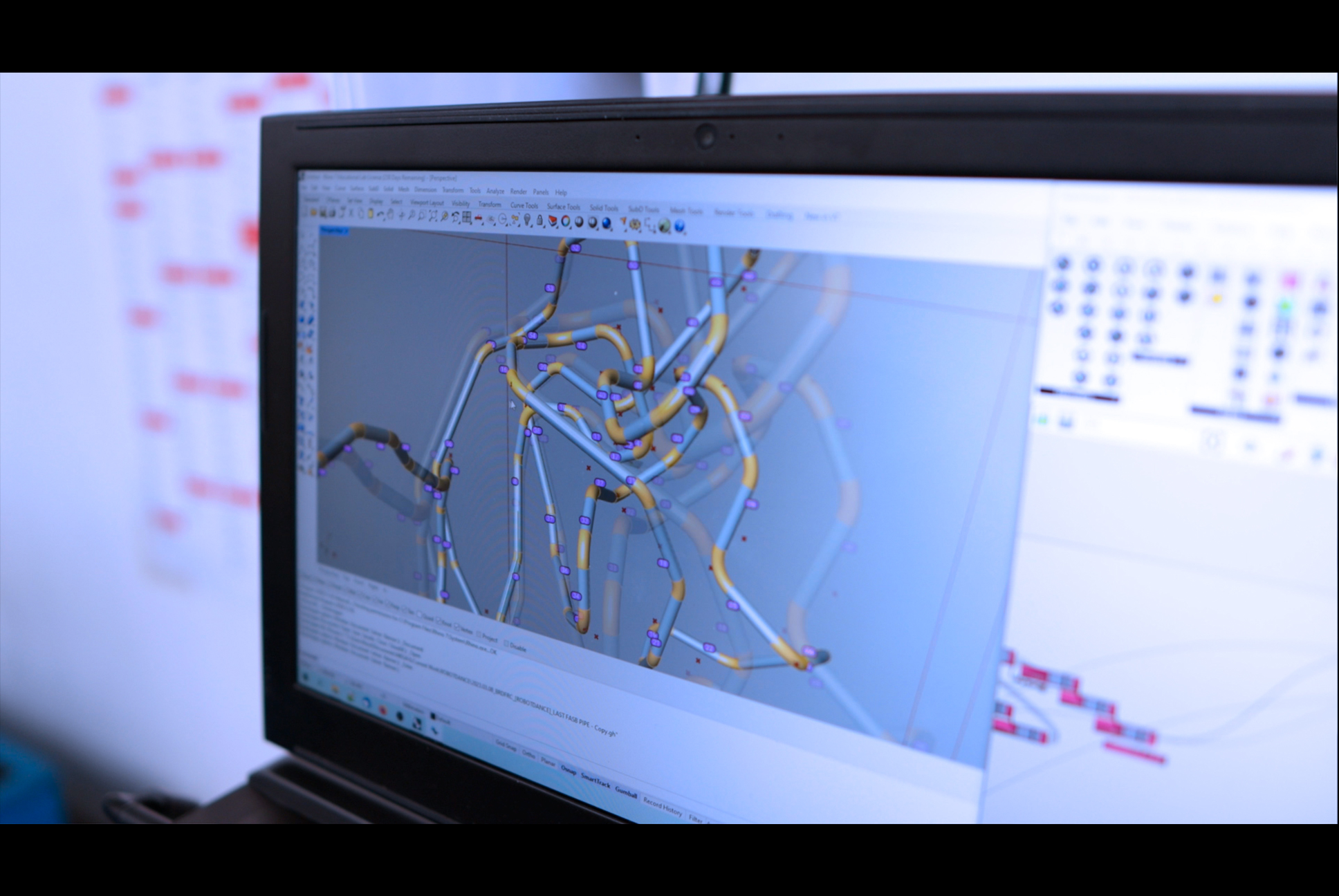

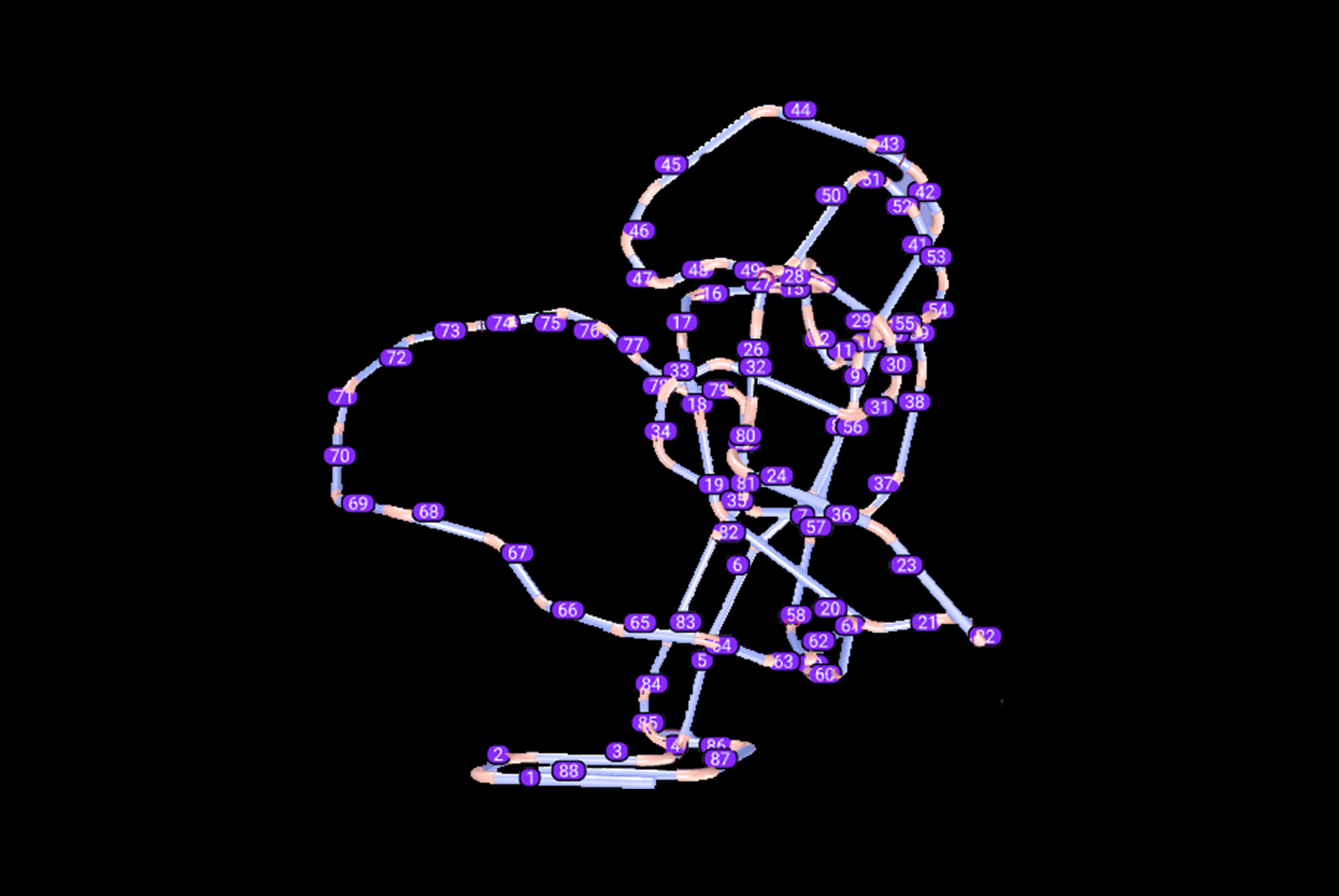

The dancer’s movements are captured and traced into dynamic trajectories using motion-tracking technology. These trajectories are reinterpreted as continuous curved lines in a parametric model, designed in Rhino and Grasshopper. The model incorporates temporal and kinetic variations, expressed through changing cross-sections along the tubular framework.

A CNC tube-bending machine shapes the structure’s unique curves, with no two bends repeating. A custom algorithm, developed by Indexlab, translates parametric data into instructions for the machine, ensuring the physical tubes reflect the computational design.

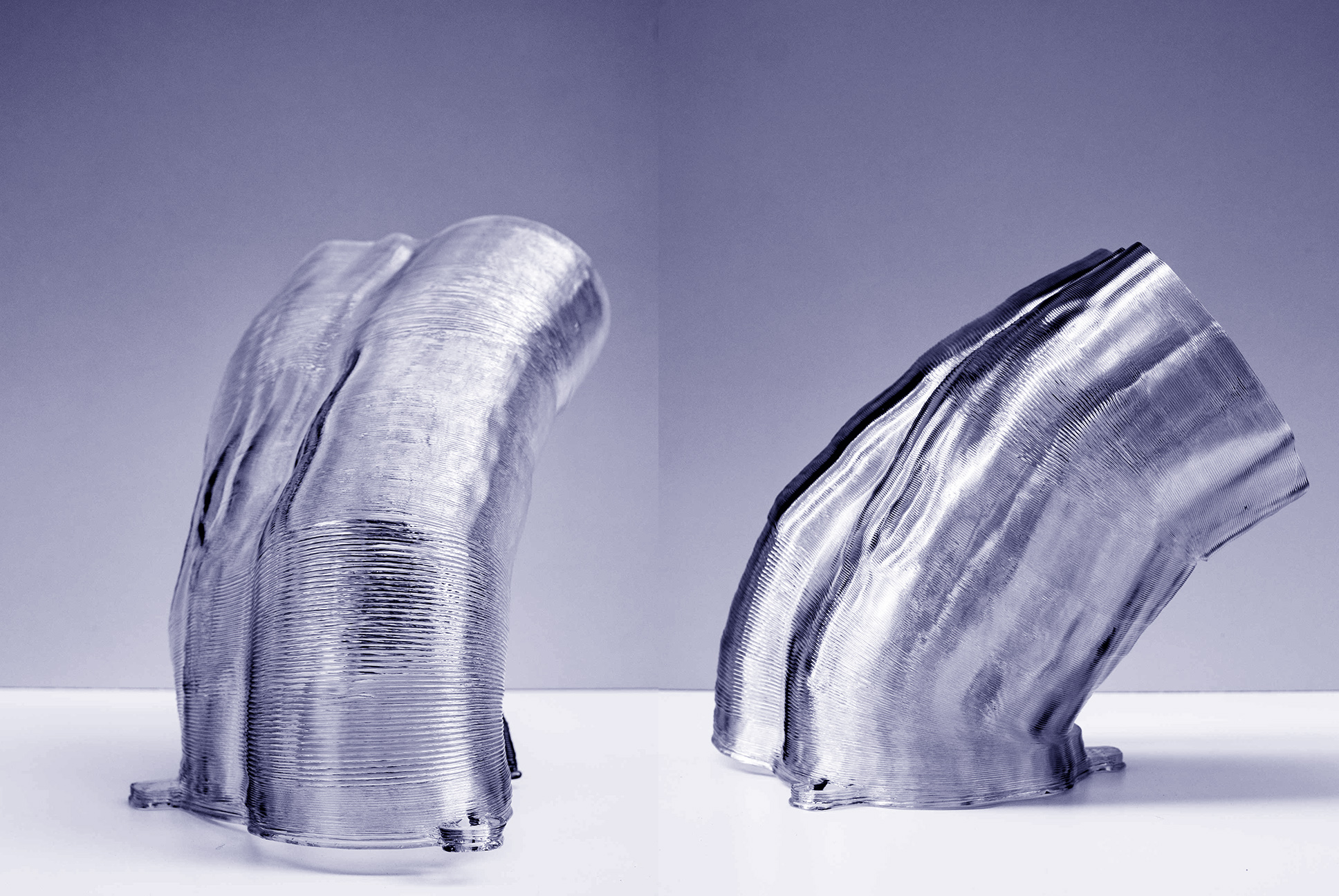

Polycarbonate modules, 3D-printed with layer variations, add another dimension of temporal expression. The assembly of these highly individualized components relies on augmented reality, which overlays a digital twin onto the physical structure. This process provides a guided sequence for accurate alignment and assembly, transforming complexity into an achievable reality.

The final installation materializes dance as a flowing, tubular structure, where every curve and cross-section embodies a specific moment of motion. CNC bending and algorithmic design create a unique identity for each segment, while augmented reality ensures precision in assembling the non-repetitive elements. The integration of parametric modeling, digital fabrication, and augmented reality highlights the ability of these tools to expand creative possibilities.

space

MATERIALS

Steel | Polycarbonate | Digital Materials

PROCESSES

Screw Extrusion | Tube Bending | Robotic 3D Printing | Augmented Reality

DESIGNS

Layering | Cardinal Splines

space

ROLES

.

STAKEHOLDERS

LOCATION

.

YEAR

2023

space