PIECE BY PIECE

Modular architectural system using interlocking wooden units for participatory, adaptable design

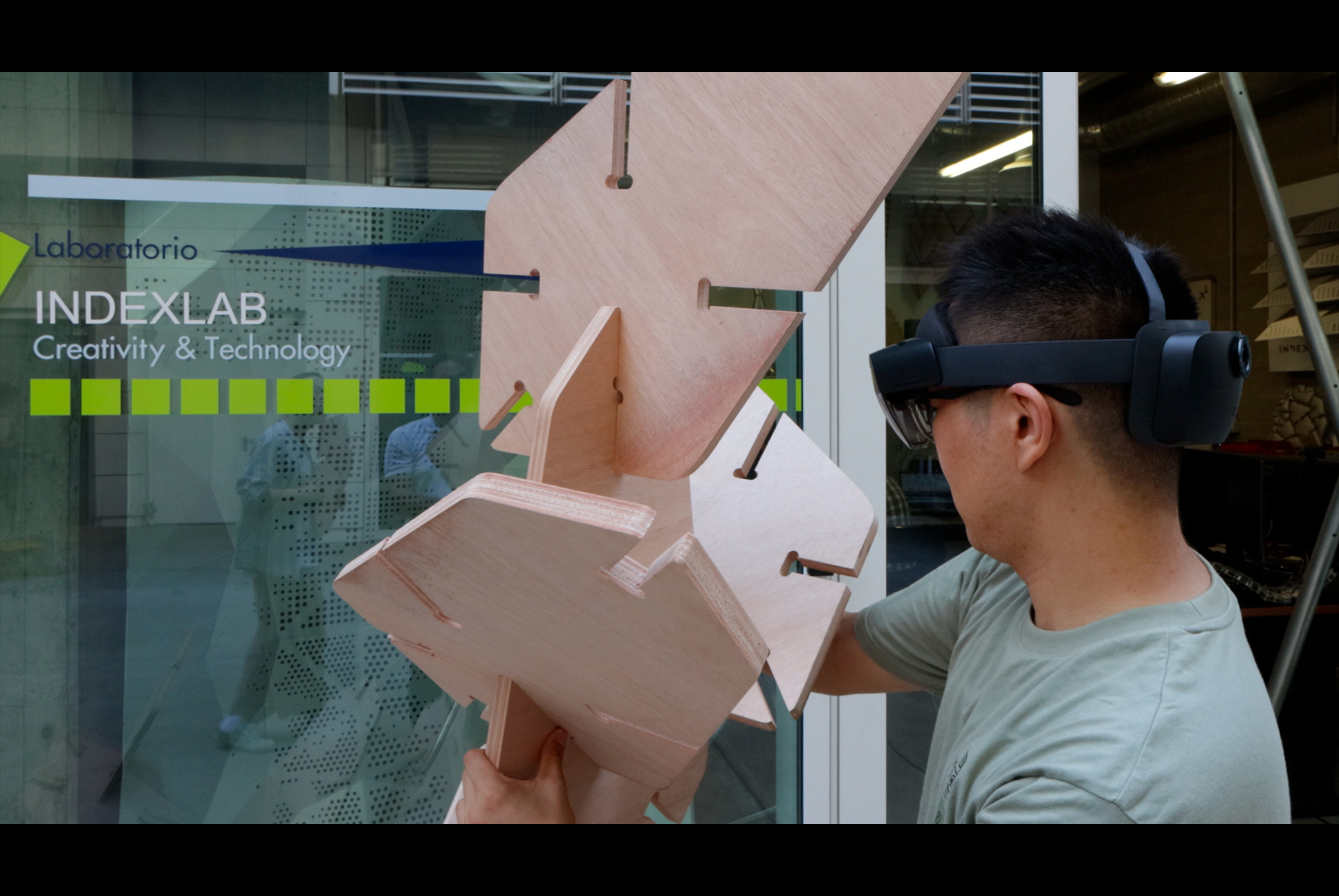

PIECE BY PIECE explores discrete architectural systems through modular, interlocking wooden units developed via algorithmic design and physical prototyping. Inspired by alpine topologies and floral geometry, the project combines top-down digital optimization with bottom-up participatory construction. The outcome is a fabrication-ready system that embeds social interaction, spatial adaptability, and material clarity into a single architectural language.

Continuous surfaces and freeform geometries often dominate computational design, yet they remain difficult to fabricate and adapt in socially driven, low-tech contexts. PIECE BY PIECE confronts this by shifting focus to discrete systems—where space is built through aggregation, not smoothing. The project seeks to merge local identity, public engagement, and architectural logic using repeatable parts that support variation, reversibility, and hands-on participation. Its core challenge is to translate symbolic forms and digital rules into a tangible structure without losing responsiveness to material and social input.

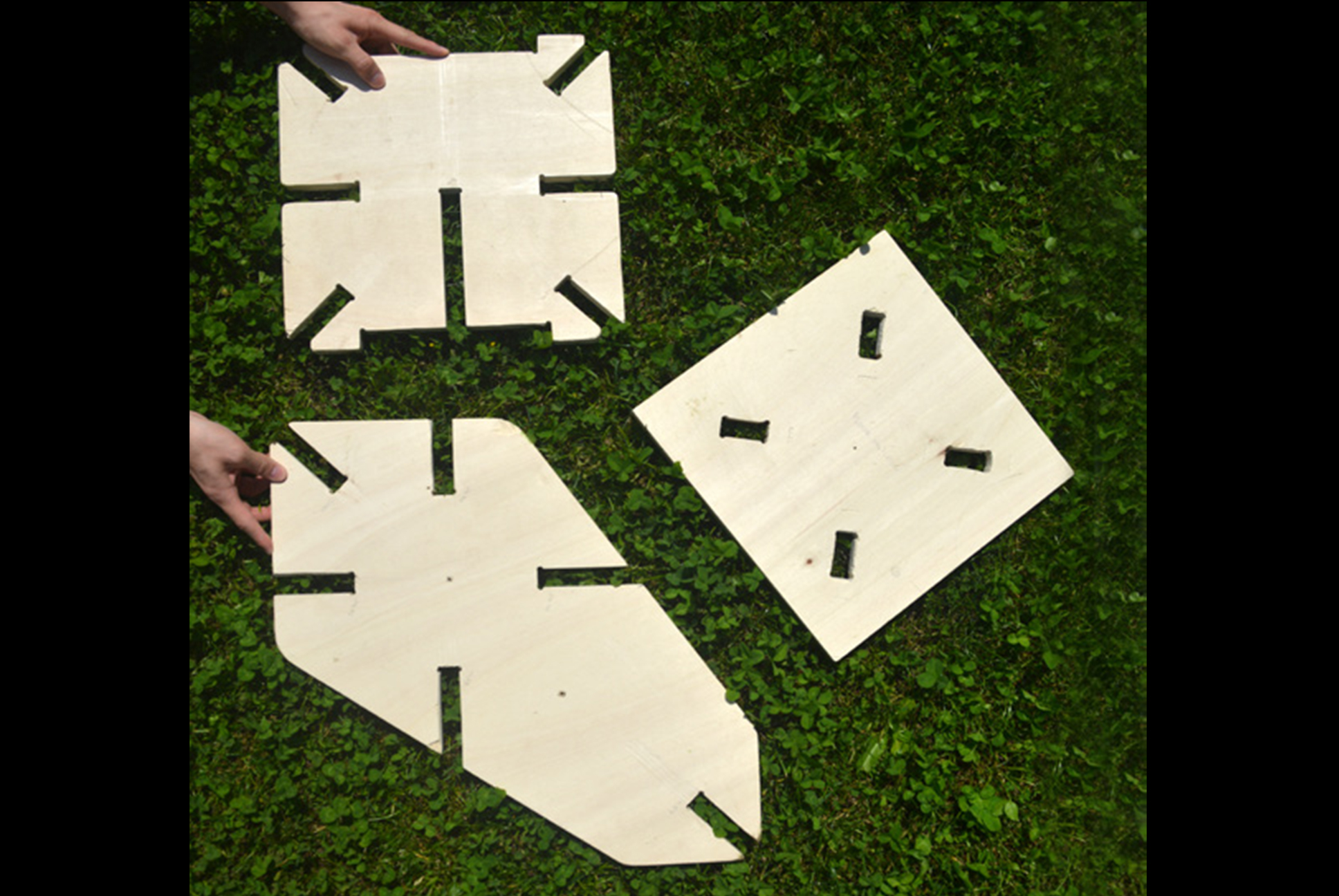

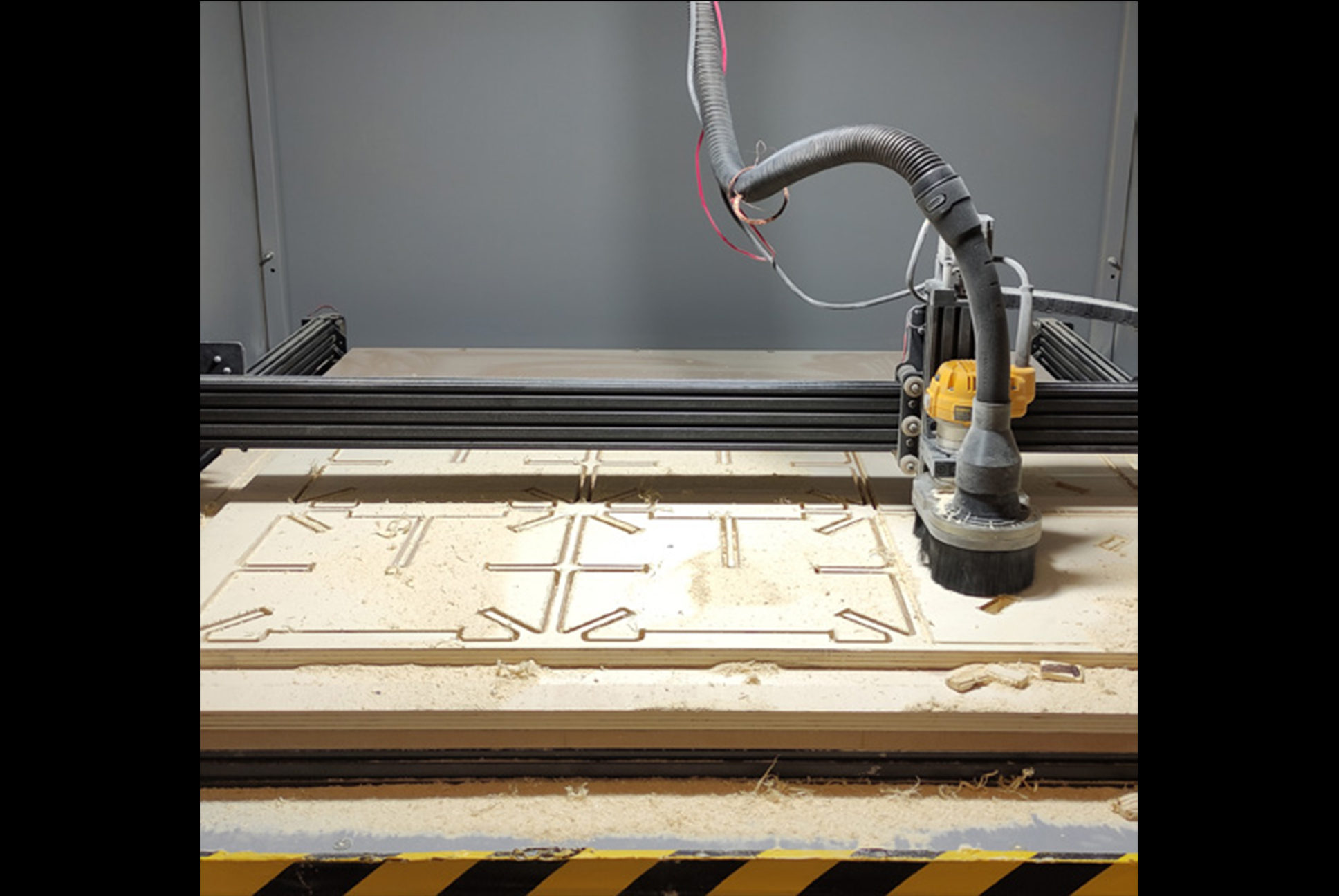

The design begins with a symbolic reference: the crocus flower, native to the Alpine region, serving as a morphological seed for the modules. Using Rhino and Grasshopper, a parametric model is developed to generate triangular cells with variable angles and thicknesses. These are aggregated using the Wasp plugin, which simulates combinations based on proximity and rule sets. Early iterations are fabricated using 3D printing to validate geometry and joint logic. Final modules are CNC-milled in wood, tested for alignment, tolerance, and joinery. The logic supports flat-packing, dry assembly, and modular recombination.

The system produces stable, non-hierarchical structures from a minimal part library. Overlapping modules maintain formal legibility while allowing open-ended growth and reconfiguration. A participatory workshop tested the assembly logic through PLA-printed components, allowing users to explore combinations, spatial potentials, and symbolic interpretations. CNC routing validated the transition from digital logic to material output, with no adhesives or fasteners required.

space

MATERIALS

Plywood | Digital Materials

PROCESSES

Routing | Cross Lap Joint | Augmented Reality

DESIGNS

Interlocking Systems | Discrete Part-Based Modularity

space

ROLES

Indexlab conceived, designed, and developed the construction system known as Piece by Piece, ultimately inventing and patenting the solution. Indexlab also combined digital optimization with participatory construction methods to create a fabrication-ready system that integrates social interaction, spatial adaptability, and material expressiveness.

STAKEHOLDERS

LOCATION

INDEXLAB - Politecnico di Milano, Polo Territoriale di Lecco, Lecco, Italy

YEAR

2024

space